U.S. Bellows, Inc. has spoken to many customers who complain about premature failure of expansion joints. In the vast majority of these cases, the issue is not a poorly made expansion joint but another issue in the piping system that places excess stress on the expansion joint.

|

|

Expansion joints are placed into piping systems for the following reasons:

- Thermal Growth (piping engineer) – The preferred method for absorbing thermal growth is an expansion loop, bend, or z. However, when there is not enough room in the system an expansion joint can be used to absorb large amounts of thermal growth in a limited space.

- Alignment and vibration (rotating equipment engineer) – Some rotating equipment engineers will use expansion joints to solve alignment and vibration issues to keep stress off of sensitive rotating equipment.

Thermal growth will move to the path of least resistance. Expansion joints are designed to be the path of least resistance with a spring rate that is much lower than expansion loops and bends. This is also what makes expansion joints the weakest element in the piping system. The issue with expansions joints is they can be sensitive to excess movement and are very sensitive to torsion. As a result, when the required movements in the piping system or overall process parameters change, it can adversely impact expansion joints. This can be caused by a lack of preventative maintenance, process changes to obtain greater output, poor installation, etc. The following are some of the scenarios PT&P has seen:

- Construction team using expansion joints for alignment – in order to save time, some construction teams will use an expansion joint to solve an alignment issue. This causes the following potential issues:

- Excess movement on expansion Joint – If the expansion is compressed to solve an alignment issue, then it will be required to compress further beyond its initial design specification to absorb thermal growth. This can significantly reduce the life of the expansion joint.

- Excess stress in piping system – If the expansion joint has limit rods, the use of the expansion joint for alignment may leave no room for the expansion joint to absorb thermal growth. In this case, the tremendous force associated with thermal growth will move to another part of the piping system.

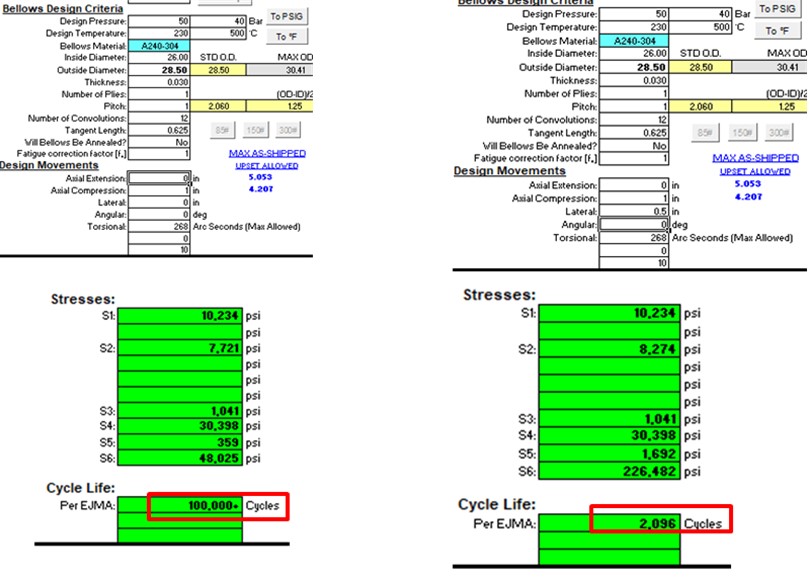

Spring support maintenance – When a spring support is not maintained, the stress and movements in the piping system can be altered significantly. For example, PT&P worked with a large chemical plant that was experiencing repeated expansion joint failures on a specific expansion joint. Upon review, the cause of the failure was that a constant spring supporting a long vertical run of piping was not being maintained. This was causing an issue for the expansion joint which was on a horizontal run of piping that was feeding the vertical piping. The chart below shows an example of the impact of expansion joint designed for 1” of axial movement when it is required to also support 0.5” of lateral movement. The requirement to support 0.5” of lateral movement reduces rates cycle life from 100,000+ cycles to 2096 cycles!

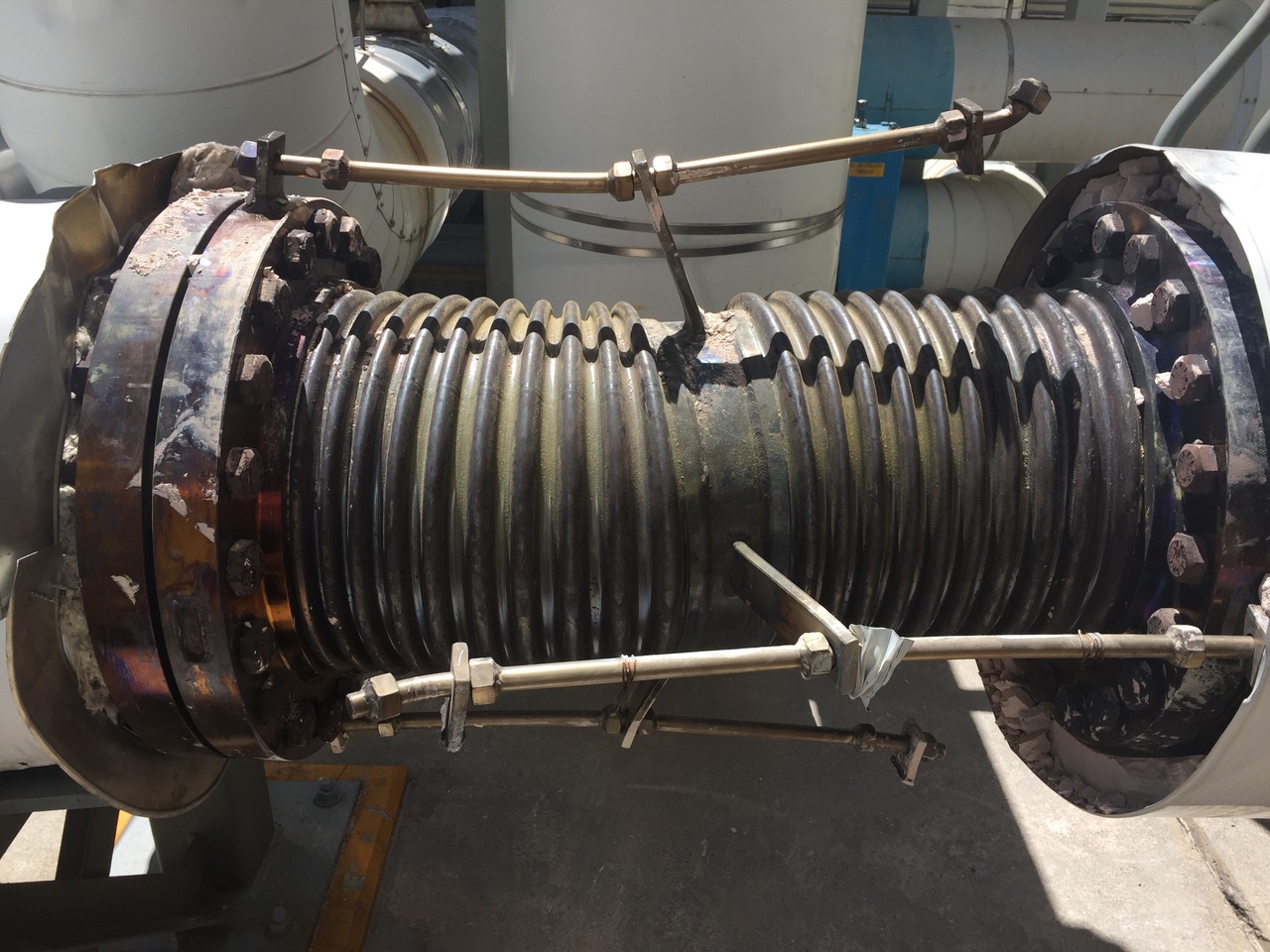

- Change in process parameters – The picture below is from a customer that experienced in-plane squirm because they raised the pressure in the piping system beyond the rated pressure of the expansion joint. Changes in pressure and temperature can move the system beyond the capability of the expansion joint. The picture below shows an in-plane squirm caused by an increase in process pressure in the piping system.

- Issues with pipe stress analysis – One of the challenges with expansion joint design in pipe stress analysis is that pipe stress software does not provide detailed specifications for expansion joints the way it does for Spring Supports and other components. As a result, a design which places excess stress on an expansion joint can pass pipe stress analysis. For example, Caesar will not keep a designer from placing excess torsional force on an expansion joint (Pipe Stress Case Study).

US Bellows recommends a strong maintenance program to avoid these issues. This includes the following:

- Maintain records of expansion joints – It is critical to know why the expansion joint was placed in the system and its intended movements.

- Regular inspection of expansion joints – Expansion joints should be inspected for cracks, corrosion, and proper movement. Given the design parameters, the expansion joint should be checked for proper positioning in hot and cold position to ensure it is being used as intended and there are no issues in the system that are going to impact the expansion joint.

- Ensure installation dimensions prior to install – To ensure that construction teams do not use expansion joints for alignment, measurements of the installation should be taken prior to installation to ensure that proper alignment has been done without the expansion joint.