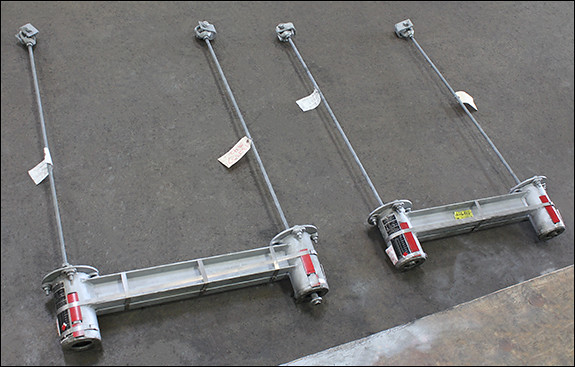

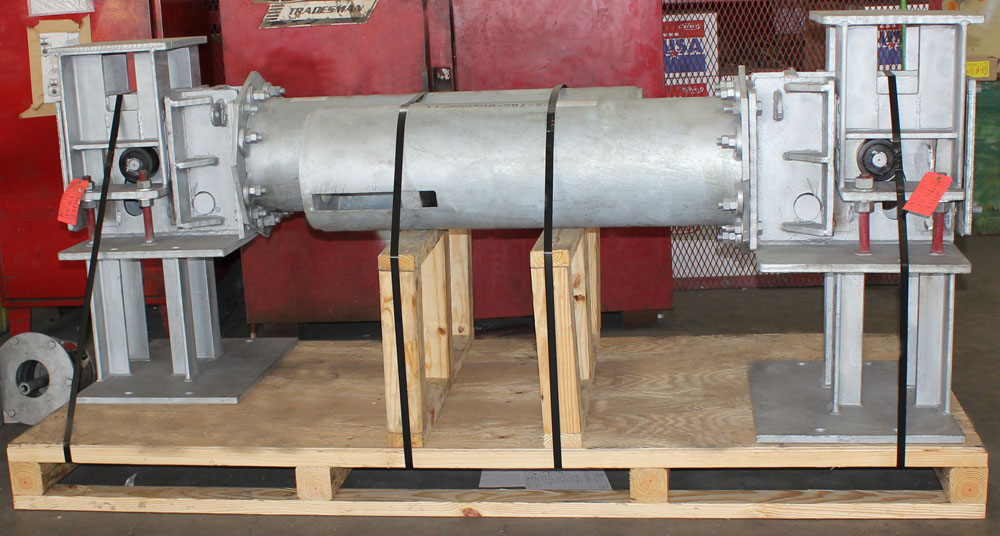

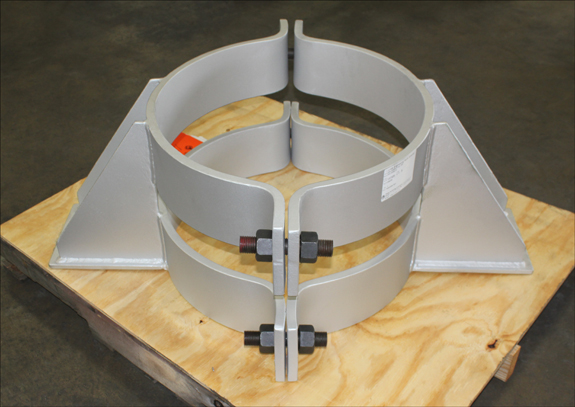

PT&P designed these G-Type variable spring support assemblies for an LNG facility in Saudi Arabia. The variables are comprised of two standard spring housing joined together with an intermediate bridge assembly. They are designed for an upwards travel range of 0.078″ to 0.118″. The variables were fabricated from carbon steel with a hot-dipped galvanized finish. Standard load and travel testing was completed prior to shipment.

Resources

Resources

Product Highlights from 2015

|

|

|

| 108″ Dia. Storage Tank and Containment Tank | Heavy Duty Yoke U-Bolt Pipe Clamps | F-Type Spring Supports for LNG |

|

|

|

|

|

| 12″ Tied Universal EJ | 46″ Dia. Inline P.B. EJ | 30″ Dia. Single Tied EJ | 84″ Dia. EJ for FCC Unit | 20″ Dia. Double Gimbal Expansion Joint |

|

|

|

| 14′ Long Sway Struts | 54″ Hot Shoes | U-Type Constant Springs |

|

|

|

| 90″ Dia. Duct Work for an Ammonia Plant | 11′ Long Fabric EJfor a Gas Turbine | 16″ Dia. Stainless Steel Single EJ’s |

|

|

|

| F-Type Constant Spring Support Assemblies | SS Rollers for a Wastewater Treatment Plant | 24″ Hold-down Clamps w/ PTFE Slide Plates for a Natural Gas Plant |

|

|

|

| 44″ Dia. Fabric EJ’s for a Chemical Plant | Tied Universal EJ for a Nitrogen Plant | 8″ Dia. Tied Universal Expansion Joints |

|

|

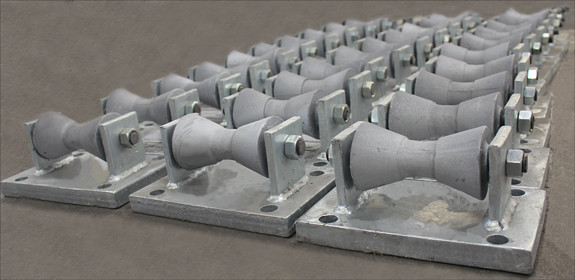

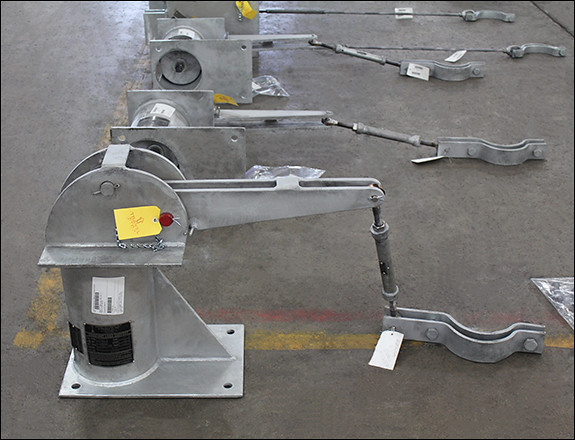

| Roller Stands Designed for a 10″ Dia. Pipeline | Sway Struts Custom Designed for a Chemical Plant |

|

|

|

| 136″ Universal EJ for a Thermal Power Plant | 10′ Long EJ for a Nuclear Energy Facility | Stainless Steel Universal EJ’s for a Pipeline |

|

|

|

| Insulated Supports for an Ammonia Project | Pipe Hanger & Clamps for Flue-gas Desulfurization | 16″ Dia. Insulated Supports for High Temperatures |

|

|

|

| 16″ Dia. Tied Universal Expansion Joints | 6″ Single Expansion Joints | 28″ Dia. Gimbal EJ with Floating Rings |

|

|

|

| C-Type Variable Spring Hangers for a Power Plant | 48″ Dia. Cold Shoes for Light Hydrocarbon Production Facility | Compact Spring Supports for a Heat Exchanger |

|

|

|

| 10″ Dia. EJ for HVAC Service | 75″ Long EJ for a Boiler Exhaust Application |

153″ Fabric EJ for a Gas Turbine Facility |

|

|

|

| Variables for a Furnace Application in an Ammonia Plant | 36″ Dia. Cryogenic Pipe Saddles for LNG Service | 42″ Dia. Chrome-Moly Pipe Clamps |

|

|

|

| 32″ Dia. Externally Pres. EJ | G-Type Variables | 20″ Dia. Inline Pressure Balanced EJ’s |

|

|

|

| F-Type Variables for a Chemical Processing Plant | Constants for a Steam Methane Reformer | Pipe Clamp Assembly for Partial Oxidation Unit in Synthetic Gas Plant |

|

|

| Gimbal EJ’s for a Flare Gas and Steam Application | Single EJ’s for a Hydrocarbon Vapor Pump |

Happy Holidays from Everyone Here at Piping Technology & Products, Inc.

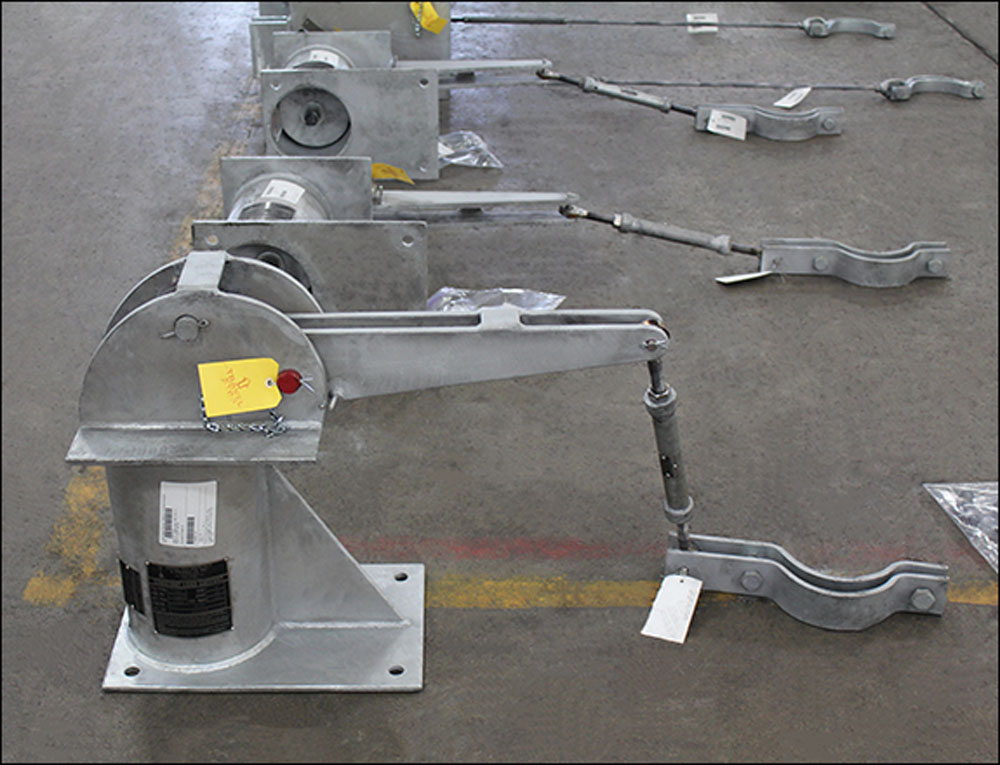

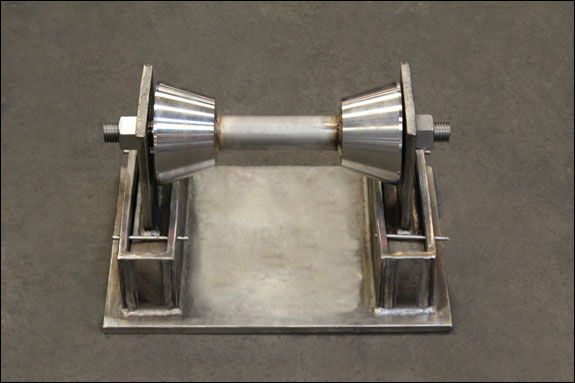

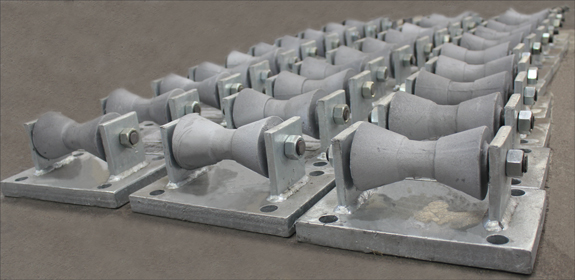

Roller Stands Designed for a Refinery in Mississippi

PT&P designed these roller stands for a refinery in Mississippi. The rollers were designed for ease of assembly to support a 10″ diameter pipeline. They are comprised of cast iron roll and sockets, steel roll rod, continuous thread rods and hex nuts. These rollers are designed to support a maximum load of 2,100 lb. and to allow axial movement of the pipeline.

Compact Spring Supports Designed for a Pump Application in Wyoming

These compact spring supports were custom designed and built within 4 weeks to support a pump for a facility in Wyoming. The housing was fabricated from A-36 carbon steel and hot-dipped galvanized to protect them against corrosion. The disc springs are engineered using the stainless steel Belleville disc springs designed for large loads but small movements. In this case, the springs are designed to support a load of 11,137 lb. and movement of 0.018″ (upward). Each assembly underwent load testing prior to shipment.

The compact size and resistance to corrosion attributes of these compact spring supports make them ideal for placement under the discharge piping of a pump at this facility. By using these compact spring supports directly on the pump, excessive thermal loading on the pump’s discharge nozzle is resolved and brings it within the pump manufacturer’s allowable limit, so the pump will operate safely, as intended which also results in extended life and low maintenance.

42" Dia. Chrome-Moly Pipe Clamps Designed for an Ammonia Plant

PT&P custom-designed pipe clamps for an ammonia facility in Louisiana. The clamps are designed for a 42″ diameter pipe and are fabricated from Chrome Moly and painted for a high heat application. The clamps support up to a 6,295 lb. load in an operating temperature range from -50 to 1000°F.

Register for the next Webinar: Engineered Spring Supports (Practical, Hands-on Approach)

This webinar is over… view the recording at: https://pipingtech.com/resources/media/webinars/

Live Webinars are worth 1 PDH Credit for TX Professional Engineers

Learn how the theoretical applications of spring supports are put into use in the real world. We will start with a review of the working principles of both variable and constant springs. See how brand new spring looks at delivery, and review installation guidelines. Learn the key points to review through the total installation process and subsequently when the springs are in operation. See how to determine if springs need adjustments, re-calibration, refurbishment or replacement. View in field examples, shutdown and isolation procedures. See the selection process required when there are significant changes to the operating condition.

The featured presenter, Jerry Godina has over 16 years experience as a pipe support designer and manages PT&P’s engineer training development program. He also inspects existing supports, consults on site remediation projects and oversees installation on a regular basis.

Custom F-Type Constant Spring Supports for Oil Refinery

PT&P designed 100-F type constant spring supports for an oil refinery in Alabama. These custom constant spring supports are 32” x 12” x 23.5” and designed to support an operating load of 650 lb. with 14” of total travel. The constants are fabricated from A36 carbon steel and the coil is from 5160H alloy material. Standard load and travel testing were completed to ensure the quality and performance of these constants.

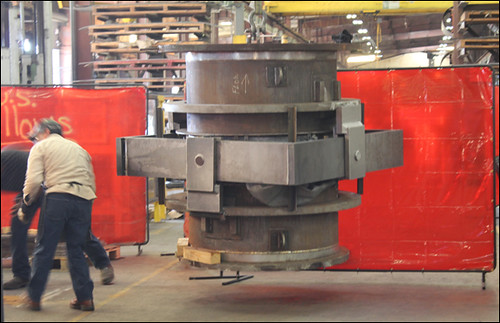

Custom Variable Spring Supports Designed for a Furnace Application in an Ammonia Plant

Custom Variable Spring Supports Designed for a Furnace Application in an Ammonia Plant.

PT&P custom designed variable spring supports and hangers for a furnace application in an ammonia plant. The furnace springs are fabricated from carbon steel and painted with a red-oxide primer to help prevent corrosion. The spring supports are designed to support loads ranging from 400 lb. to 12,500 lb. Over 150 spring coils underwent calibration test prior to fabrication and insertion into the variable support housing to ensure variance of less than 5%.

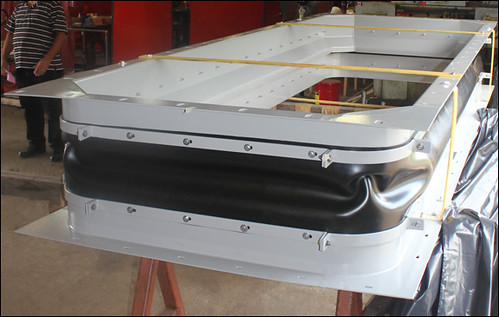

24" Hold-down Clamps for a Natural Gas Plant in Colorado

24″ Diameter HD-2 Hold-down Clamps for a Natural Gas Plant in Colorado.

PT&P designed and manufactured these standard HD-2 hold-down clamps for a natural gas plant in Colorado. They are fabricated from carbon steel and designed with PTFE slide plates. The hold-downs are designed for 8″ to 24″ diameter pipes and operating temperature up to 400°F.

What are individual Stress-Intensification Factors (SIF) applied for?

Welds, fittings, branch connections , and other piping components where the possibility of fatigue failure could occur.

What is the Stress-Intensification Factor?

The Stress-Intensification Factor is the ratio of the maximum stress intensity compared to the nominal stress.

Compact Disc Spring Support Designed for a Heat Exchanger Application

Compact Disc Spring Support Designed for a Heat Exchanger Application

In this application, the heat exchanger (vertical vessel), has thermal movement of 1/4″, vertically. As it expands thermally, the vessel lifts off its support structure and additional forces at the vessel’s lower nozzle are created. With many heat exchangers, as well as other process equipment, the space between the support structure and equipment is restricted. In this case, the space between the cantilever clamp attached to the vessel and the support structure is limited to only 5.1″. This lack of space is unsuitable for placing the conventional spring supports which require more space.

The Compact Disc Spring support is designed to support large loads in small confined spaces with limited thermal movement (from 0 to 3/4″). By supporting the vessel with Disc Springs, the thermal movement is allowed (or relieved), which helps reduce the excessive loads and local stress on the nozzles. This results in compliance with the ASME Piping and Vessel Codes. Due to a corrosive chemical plant environment, the two Compact Disc Spring supports were supplied with engineered 17-7PH Stainless Steel Belleville Disc Springs to combat corrosion.

What does the Maximum Shear Stress Theory state?

The maximum shear stress theory states that failure of a piping component occurs when the maximum shear stress exceeds the shear stress at the yield point in a tensile test.

What does the Maximum Principle Stress Theory state?

This theory states that yielding in a piping component occurs when the magnitude of any of the three mutually perpendicular principal stresses exceeds the yield strength of the material.

Out of the Six Theories of Failure, which are the 2 that are the most widely used?

The Maximum Principle Stress Theory and Maximum Shear Stress Theory

What are the 5 modes of failure of piping design?

Failure by general yielding, yielding at sub-elevated temperature, brittle fractures, and fatigue.

What is the purpose of Stress Analysis?

Stress analysis ensures the safety of piping and piping components, safety of connected equipment and supporting structure, and that piping deflections are within limits.

What is Stress Analysis?

A term applied to calculations, which address the static and dynamic loading, resulting from the effects of gravity, temperature changes, internal pressures, fluid flow, seismic activity, and any external loads.

What is the Stress-Strain curve?

It is a visual representation of the effects of various loading conditions on a piping system between stress and strain.