TYPES & SIZES

Technical Information

Methods of Protecting against Corrosion

Considering All Movement in Pipe Support Design

Comparative Corrosion Resistance Guide

Request a Quote

Pipe support hardware is used to assemble a pipe hanger assembly.

Methods of Protecting against Corrosion

Considering All Movement in Pipe Support Design

Comparative Corrosion Resistance Guide

Ammonia Plant

Chemical Plant

Clean Fuels

Commercial

Electric Plant

Energy Facility

Ethylene Plant

LLDPE Chemical Plant

LNG Plant

MTBE Plant

Natural Gas Combined Cycle Facility

Natural Gas Processing & Separation

Oil Refinery

Oil Sand Mine

Paper Manufacturer

See All

U-bolts can be utilized as pipe guides when the horizontal forces are relatively small (usually 10% or less) compared with ...Continue Reading

Linked eye rods are primarily used in rod hanger assemblies where lateralor axial pipe movement must be accommodated. Linked Eye ...Continue Reading

An eye rod is a hanger rod where the lower section consists of either a formed portion (to form an ...Continue Reading

Long tangent refers to the length of the straight leg portion of the u-bolt which specifies the height of the ...Continue Reading

In order to specify a u-bolt for pipes, you must provide the diameter of the pipe, the material, the tangent ...Continue Reading

When installing clevises, first you should disengage the pin connection of the clevis. Then align the clevis pin holes with ...Continue Reading

Fabricated Forged

MATERIAL: Carbon steel

FINISH: Black or galvanized, furnished black unless otherwise specified.

SERVICE: Provides adjustment up to 6” for heavy loads.

ORDERING: Specify figure number, rod size, description and finish. We may supply fabricated or forged.

|

ROD SIZE

|

MAX. RECOM. LOAD (lb.) |

S

|

T

|

WEIGHT (lb. per 100) |

|

|---|---|---|---|---|---|

|

A

|

@650° F

|

@750° F

|

|||

|

3/8

|

730

|

572

|

7 1/4

|

5/8

|

34

|

|

1/2

|

1350

|

1057

|

7 1/2

|

3/4

|

47

|

|

5/8

|

2160

|

1692

|

7 3/4

|

7/8

|

86

|

|

3/4

|

3230

|

2530

|

8 1/4

|

1 1/8

|

134

|

|

7/8

|

4480

|

3508

|

8 1/2

|

1 1/4

|

190

|

|

1

|

5900

|

4620

|

9

|

1 1/2

|

247

|

|

1 1/8

|

7660

|

5560

|

9 1/4

|

1 5/8

|

338

|

|

1 1/4

|

9500

|

7440

|

9 1/4

|

1 5/8

|

330

|

|

1 1/2

|

13800

|

10807

|

9 3/4

|

1 7/8

|

530

|

|

1 3/4

|

18600

|

14566

|

10 1/2

|

2 1/4

|

780

|

|

2

|

24600

|

19265

|

11

|

2 1/2

|

1195

|

|

2 1/4

|

32300

|

25295

|

12 1/4

|

3 1/8

|

2700

|

|

2 1/2

|

39800

|

31169

|

12 1/4

|

3 1/8

|

2690

|

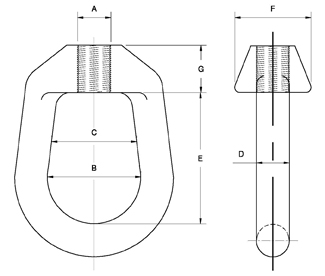

MATERIAL: Forged steel

SERVICE: For use on high temperature piping installation.

FEATURES:

• Supports loads equal to the full limitation of the hanger rod.

• Provides flexible connection when used with straight thread rods.

ORDERING: Specify figure number, rod size, description, rod tapping and finish.

|

SIZE NO.

|

ROD SIZE A

|

MAX. RECOM. LOAD (lbs.) |

B

|

C

|

D

|

E

|

F

|

G

|

APPROX. WEIGHT (lbs. per 100) |

|

|---|---|---|---|---|---|---|---|---|---|---|

|

@650°F

|

@750°F

|

|||||||||

|

1

|

3/8

|

730

|

572

|

1 1/2

|

1 3/16

|

1/2

|

2

|

1 3/8

|

11/16

|

68

|

|

1/2

|

1350

|

1057

|

69

|

|||||||

|

5/8

|

2160

|

1692

|

66

|

|||||||

|

3/4

|

3230

|

2530

|

59

|

|||||||

|

2

|

7/8

|

4480

|

3508

|

2

|

1 11/16

|

3/4

|

2 5/8

|

1 15/16

|

1

|

170

|

|

1

|

5900

|

4620

|

170

|

|||||||

|

3

|

1 1/8

|

7660

|

5560

|

2 1/2

|

1 13/16

|

1

|

3 3/8

|

2 3/8

|

1 1/4

|

380

|

|

1 1/4

|

9500

|

7440

|

380

|

|||||||

|

1 1/2

|

13800

|

10807

|

350

|

|||||||

|

4

|

1 3/4

|

18600

|

14566

|

4

|

4

|

1 1/2

|

6 1/4

|

4

|

2 1/4

|

1890

|

|

2

|

24600

|

19265

|

1890

|

|||||||

|

2 1/4

|

32300

|

25295

|

1800

|

|||||||

|

2 1/2

|

39800

|

31169

|

1660

|

|||||||

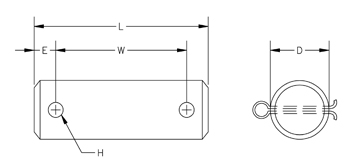

MATERIAL: Carbon steel

FINISH: Black or galvanized

SERVICE: To be used as an option to support the load on Type C variable spring hangers, Type C constant supports,Fig. 95 clevises, and Fig. 20 welded beam attachment.

ORDERING: Specify figure number, pin diameter, description, finish, and if cotter pins are needed. If planning to use the clevis pin with any of the above mentioned figures, please list which figure in the order instructions.

|

PIN DIA. D

|

MAX. LOAD (lb.)

|

WEIGHT

|

L

|

W

|

E

|

H

|

COTTER PIN SIZE

|

|

|---|---|---|---|---|---|---|---|---|

| @650°F | @750°F | |||||||

|

1/2

|

730

|

572

|

0.12

|

2 7/8

|

2 1/8

|

3/8

|

3/32

|

1/8 x 1 1/4

|

|

5/8

|

1350

|

1057

|

0.18

|

3 1/8

|

2 3/8

|

3/8

|

3/32

|

1/8 x 1 1/4

|

|

3/4

|

2160

|

1691

|

0.29

|

3 5/8

|

2 7/8

|

3/8

|

7/32

|

3/16 x 1 1/2

|

|

7/8

|

3230

|

2529

|

0.47

|

4

|

3 1/4

|

3/8

|

7/32

|

3/16 x 1 1/2

|

|

1

|

4480

|

3508

|

0.67

|

4

|

3 1/4

|

3/8

|

7/32

|

3/16 x 2

|

|

1 1/8

|

5900

|

4620

|

1.00

|

4 3/4

|

4

|

3/8

|

7/32

|

3/16 x 2

|

|

1 1/4

|

7410

|

5802

|

1.70

|

4 7/8

|

4 1/4

|

3/8

|

9/32

|

1/4 x 2

|

|

1 3/8

|

9500

|

7439

|

2.10

|

5 3/8

|

4 3/8

|

1/2

|

9/32

|

1/4 x 2

|

|

1 5/8

|

13800

|

10805

|

3.30

|

6

|

5

|

1/2

|

9/32

|

1/4 x 2

|

|

1 7/8

|

18600

|

14564

|

4.80

|

7 1/8

|

5 7/8

|

5/8

|

3/8

|

3/8 x 3

|

|

2 1/4

|

24600

|

19262

|

7.20

|

7 1/8

|

5 7/8

|

5/8

|

3/8

|

3/8 x 4

|

|

2 1/2

|

32300

|

25291

|

9.30

|

7 5/8

|

6 3/8

|

5/8

|

3/8

|

3/8 x 4

|

|

2 3/4

|

39800

|

31163

|

12.50

|

7 7/8

|

6 5/8

|

5/8

|

3/8

|

3/8 x 4

|

|

3

|

49400

|

38680

|

16.60

|

8 1/4

|

6 3/4

|

3/4

|

1/2

|

1/2 x 5

|

|

3 1/4

|

60100

|

47058

|

20.00

|

8 1/2

|

7

|

3/4

|

1/2

|

1/2 x 5

|

|

3 1/2

|

71900

|

56298

|

23.90

|

8 3/4

|

7 1/4

|

3/4

|

1/2

|

1/2 x 5

|

|

3 3/4

|

84700

|

66320

|

25.10

|

9 1/2

|

8

|

3/4

|

1/2

|

1/2 x 6

|

|

4

|

98500

|

77125

|

34.80

|

9 3/4

|

8 1/4

|

3/4

|

1/2

|

1/2 x 6

|

MATERIAL: Carbon Steel

FINISH: Black

SERVICE: For use on top of channels or angles to support pipe with rods or U-Bolts

ORDERING: Specify figure number, rod size, description and finish.

|

ROD SIZE

|

HOLE DIAMETER

|

SIZE OF STEEL

|

APPROXIMATE WEIGHT lbs. per 100

|

|---|---|---|---|

| A x A x B | |||

|

3/8

|

1/2

|

3 x 3 x 1/4

|

6.2

|

|

1/2

|

5/8

|

3 x 3 x 1/4

|

6.2

|

|

5/8

|

3/4

|

3 x 3 x 3/8

|

9.1

|

|

3/4

|

7/8

|

4 x 4 x 3/8

|

16.0

|

|

7/8

|

1

|

4 x 4 x 1/2

|

22.0

|

|

1

|

1 1/4

|

4 x 4 x 1/2

|

21.0

|

|

1 1/4

|

1 1/2

|

5 x 5 x 1/2

|

33.0

|

|

1 1/2

|

1 3/4

|

5 x 5 x 3/4

|

48.0

|

|

1 3/4

|

2

|

5 x 5 x 3/4

|

47.0

|

|

2

|

2 1/4

|

5 x 5 x 3/4

|

45.0

|

|

2 1/4

|

2 1/2

|

6 x 6 x 3/4

|

66.0

|

|

2 1/2

|

2 3/4

|

6 x 6 x 3/4

|

64.0

|

|

2 3/4

|

3

|

6 x 6 x 3/4

|

62.0

|

|

3

|

3 1/4

|

6 x 6 x 3/4

|

59.0

|

|

3 1/4

|

3 1/2

|

6 x 6 x 3/4

|

56.0

|

|

3 1/2

|

3 3/4

|

7 x 7 x 3/4

|

81.0

|

|

3 3/4

|

4

|

7 x 7 x 3/4

|

78.0

|

MATERIAL: Carbon steel

SERVICE: For use on high temperature piping installation.

FEATURES:

• Complies fully with the code for pressure piping.

• Supports loads equal to the full limitation of the hanger rod.

ORDERING: Specify figure number, body size, description, rod tapping, size of pin hole, size of pin, size of grip and finish. We may supply fabricated or forged.

|

ROD SIZE

|

MAX RECOM. LOAD, lbs. |

APPROX. WEIGHT lb./ each |

BODY SIZE NO. |

PIN SIZE P

|

A

|

D

|

N

|

T

|

W

|

MAX. GRIP

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

650 °F

|

750 °F

|

||||||||||

|

3/8

|

730

|

572

|

1

|

2

|

1/2

|

3 7/8

|

1 7/16

|

5/8

|

5/16

|

1 1/16

|

5/8

|

|

1/2

|

1350

|

1057

|

.9

|

5/8

|

3 7/8

|

1 7/16

|

5/8

|

5/16

|

1 1/16

|

5/8

|

|

|

5/8

|

2160

|

1692

|

.9

|

3/4

|

3 7/8

|

1 7/16

|

5/8

|

5/16

|

1 1/16

|

5/8

|

|

|

3/4

|

3230

|

2530

|

2.5

|

2 1/2

|

7/8

|

4

|

2 1/2

|

1 1/8

|

5/16

|

1 1/4

|

7/8

|

|

7/8

|

4480

|

3508

|

2.5

|

1

|

4

|

2 1/2

|

1 1/8

|

5/16

|

1 1/4

|

7/8

|

|

|

1

|

5900

|

4620

|

4

|

3

|

1 1/8

|

5

|

3

|

1 5/16

|

1/2

|

1 1/2

|

1 1/4

|

|

1 1/8

|

7660

|

4620

|

4

|

1 1/4

|

5

|

3

|

1 5/16

|

1/2

|

1 1/2

|

1 1/4

|

|

|

1 1/4

|

9500

|

7440

|

4

|

1 3/8

|

5

|

3

|

1 5/16

|

1/2

|

1 1/2

|

1 1/4

|

|

|

1 1/2

|

13800

|

10807

|

6

|

3 1/2

|

1 5/8

|

6

|

3 1/2

|

1 5/8

|

1/2

|

1 3/4

|

1 1/2

|

|

1 3/4

|

18600

|

14566

|

8

|

4

|

1 7/8

|

6

|

4

|

1 3/4

|

1/2

|

2

|

1 1/2

|

|

2

|

24600

|

19265

|

16

|

5

|

2 1/4

|

7

|

5

|

2 1/4

|

5/8

|

2 1/2

|

2 1/2

|

|

2 1/4

|

32300

|

25295

|

26

|

6

|

2 1/2

|

8

|

6

|

2 3/4

|

3/4

|

3

|

2 1/2

|

|

2 1/2

|

39800

|

31169

|

26

|

2 3/4

|

8

|

6

|

2 3/4

|

3/4

|

3

|

2 1/2

|

|

MATERIAL: Cast iron roll, carbon steel yoke, roll rod, and hex nuts.

SERVICE: For suspension of pipe from a single rod where horizontal movement may occur because of expansion or contraction.

HOW TO SIZE: If the roll is to support bare pipe, select the size directly from the nominal pipe size (see table below).

ORDERING: Specify figure number, pipe size, description and finish.

|

NOMINAL PIPE SIZE |

MAX. O.D. OF COVERING |

MAX. RECOM. LOAD, lb. |

APPROX. WEIGHT (lb. per 100) |

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

|---|---|---|---|---|---|---|---|---|---|---|---|

|

2 1/2

|

3

|

225

|

170

|

1/2

|

5 3/4

|

3 1/4

|

1 15/16

|

2 7/8

|

1/2

|

3/16 x 1

|

1 11/16

|

|

3

|

3 5/8

|

310

|

220

|

1/2

|

6 3/8

|

3 7/8

|

2 1/4

|

3 1/8

|

1/2

|

1/4 x 1

|

1 5/8

|

|

3 1/2

|

4 1/8

|

390

|

253

|

1/2

|

7

|

4 3/8

|

2 9/16

|

3 1/2

|

1/2

|

1/4 x 1 1/4 |

1 11/16

|

|

4

|

4 11/16

|

475

|

321

|

5/8

|

7 9/16

|

4 15/16

|

2 13/16

|

3 5/8

|

1/2

|

1/4 x 1 1/2 |

1 5/8

|

|

5

|

5 3/4

|

685

|

627

|

5/8

|

9 1/8

|

6

|

3 7/16

|

4 1/2

|

5/8

|

3/8 x 1 3/4 |

1 15/16

|

|

6

|

6 7/8

|

780

|

927

|

3/4

|

10 5/16

|

7 1/8

|

4

|

5

|

3/4

|

3/8 x 2

|

1 7/8

|

|

8

|

9

|

780

|

1454

|

7/8

|

12 11/16

|

9 1/4

|

5 1/8

|

6 1/8

|

7/8

|

3/8 x 2 1/2 |

2

|

|

10

|

11

|

965

|

1880

|

7/8

|

15 1/16

|

11 1/4

|

6 3/8

|

7 1/4

|

7/8

|

3/8 x 2 1/2 |

2 1/16

|

|

12

|

13

|

1200

|

2774

|

7/8

|

17 7/16

|

13 1/4

|

7 7/16

|

8 3/8

|

1

|

1/2 x 2 1/2 |

2 1/4

|

|

14

|

14 1/4

|

1200

|

3913

|

1

|

18 7/8

|

14 1/2

|

8 3/8

|

8 3/4

|

1 1/8

|

1/2 x 2 1/2 |

2

|

|

16

|

16 1/4

|

1200

|

4905

|

1

|

20 13/16

|

16 1/2

|

9 3/8

|

9 11/16

|

1 1/4

|

1/2 x 2 1/2 |

1 15/16

|

|

18

|

18 1/4

|

1400

|

5780

|

1 1/8

|

23 3/4

|

18 1/2

|

10 7/16

|

11 7/16

|

1 1/4

|

1/2 x 3

|

2 11/16

|

|

20

|

20 1/4

|

1600

|

7594

|

1 1/4

|

26

|

20 1/2

|

11 5/8

|

12 1/4

|

1 3/8

|

5/8 x 3

|

2 1/2

|

MATERIAL: Cast iron roll and sockets; steel roll rod.

SERVICE: For suspension of pipe from two rods where longitudinal movement due to expansion or contraction may occur.

ADJUSTMENT: Adjustment socket permits vertical adjustment at the roll.

HOW TO SIZE:

1. If the roll is to support non-insulated pipe, select the size directly from nominal pipe size.

2. If used with pipe covering protection saddle, see Fig, 184, 185, 186, 187, 188, and 189 for size of pipe roll.

3. If roll is to support covered pipe, select the nominal pipe size (column 1) which corresponds to the O.D. of covering and saddle (column 2).

ORDERING: Specify figure number, nominal pipe size, description and finish.

|

NOMINAL PIPE SIZE |

MAX. O.D. OF COVERING |

ADJUSTED SOCKET No. |

MAX. RECOM.SAFE LOAD (lb.) |

APPROX. WEIGHT (lb. per 100) |

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

J

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

1

|

2

|

1 — 3/8

|

600

|

45

|

4 1/8

|

3

|

1 1/2

|

1

|

3/4

|

3/8

|

3/8

|

1 1/16

|

9/16

|

|

1 1/4

|

2 1/2

|

1 — 3/8

|

600

|

48

|

4 1/2

|

3 3/8

|

1 7/8

|

1 1/16

|

3/4

|

3/8

|

3/8

|

1 1/4

|

9/16

|

|

1 1/2

|

2 3/4

|

1 — 3/8

|

600

|

51

|

4 3/4

|

3 5/8

|

2 1/8

|

1 1/8

|

3/4

|

3/8

|

3/8

|

1 3/8

|

9/16

|

|

2

|

3 1/4

|

1 — 3/8

|

600

|

57

|

5 1/4

|

4 1/8

|

2 5/8

|

1 3/16

|

3/4

|

3/8

|

3/8

|

1 5/8

|

9/16

|

|

2 1/2

|

3 3/4

|

2 — 1/2

|

660

|

100

|

6 1/4

|

4 7/8

|

3 1/8

|

1 3/8

|

7/8

|

1/2

|

1/2

|

1 15/16

|

11/16

|

|

3

|

4 1/2

|

2 — 1/2

|

700

|

110

|

6 7/8

|

5 1/2

|

3 3/4

|

1 7/16

|

7/8

|

1/2

|

1/2

|

2 1/4

|

11/16

|

|

3 1/2

|

5

|

2 — 1/2

|

750

|

135

|

7 1/2

|

6 1/8

|

4 1/4

|

1 5/8

|

1

|

1/2

|

1/2

|

2 9/16

|

3/4

|

|

3 — 1/2

|

150

|

7 3/4

|

6 1/4

|

5/8

|

3/4

|

||||||||

|

4

|

5 1/2

|

2 — 1/2

|

750

|

150

|

8

|

6 5/8

|

4 3/4

|

1 3/4

|

1

|

1/2

|

1/2

|

2 13/16

|

3/4

|

|

3 — 1/2

|

165

|

8 1/4

|

6 3/4

|

5/8

|

3/4

|

||||||||

|

5

|

7

|

2 — 5/8

|

750

|

226

|

9 7/16

|

8 1/16

|

5 13/16

|

2

|

1 1/8

|

5/8

|

1/2

|

3 7/16

|

13/16

|

|

3 — 5/8

|

257

|

9 11/16

|

5/8

|

7/8

|

|||||||||

|

6

|

8 1/4

|

2 — 3/4

|

1070

|

378

|

10 15/16

|

9 9/16

|

6 7/8

|

2 5/16

|

1 1/4

|

3/4

|

1/2

|

4

|

7/8

|

|

3 — 3/4

|

416

|

11 3/16

|

5/8

|

1

|

|||||||||

|

4 — 3/4

|

445

|

11 7/16

|

3/4

|

1

|

|||||||||

|

8

|

10 1/2

|

2 — 7/8

|

1350

|

585

|

13 5/16

|

11 15/16

|

8 7/8

|

2 13/16

|

1 1/2

|

7/8

|

1/2

|

5 1/8

|

15/16

|

|

3 — 7/8

|

625

|

13 9/16

|

5/8

|

1 1/16

|

|||||||||

|

4 — 7/8

|

690

|

13 13/16

|

3/4

|

1 3/16

|

|||||||||

|

5 — 7/8

|

715

|

14 1/16

|

7/8

|

1 1/8

|

|||||||||

|

10

|

12 3/4

|

2 — 7/8

|

1730

|

838

|

15 7/16

|

14 1/16

|

11

|

3 3/8

|

1 3/4

|

7/8

|

1/2

|

6 3/8

|

15/16

|

|

3 — 7/8

|

862

|

15 11/16

|

5/8

|

1 1/16

|

|||||||||

|

4 — 7/8

|

920

|

15 15/16

|

3/4

|

1 3/16

|

|||||||||

|

5 — 7/8

|

950

|

16 3/16

|

7/8

|

1 1/8

|

|||||||||

|

12

|

14 3/4

|

3 — 1

|

2400

|

1465

|

17 7/16

|

15 13/16

|

12 1/2

|

3 7/8

|

2

|

1

|

5/8

|

7 7/16

|

1 1/8

|

|

4 — 1

|

1525

|

17 11/16

|

3/4

|

1 1/4

|

|||||||||

|

5 — 1

|

1590

|

17 15/16

|

7/8

|

1 1/4

|

|||||||||

|

14

|

16 1/4

|

5 — 1 1/8

|

3130

|

2360

|

19 7/8

|

17 3/4

|

14 1/4

|

4 5/8

|

2 1/2

|

1 1/8

|

7/8

|

8 3/8

|

1 7/16

|

|

6 — 1 1/8

|

2425

|

20 1/8

|

1

|

1 3/8

|

|||||||||

|

16

|

18

|

5 — 1 1/4

|

3970

|

3080

|

21 7/8

|

19 3/4

|

16 1/4

|

5

|

2 5/8

|

1 1/4

|

7/8

|

9 7/16

|

1 1/2

|

|

6 — 1 1/4

|

3185

|

22 1/8

|

1

|

1 1/2

|

|||||||||

|

7 — 1 1/4

|

3260

|

22 3/8

|

1 1/8

|

1 1/2

|

|||||||||

|

18

|

20 1/4

|

5 — 1 1/4

|

4200

|

3370

|

24

|

21 7/8

|

18 1/4

|

5 7/16

|

2 3/4

|

1 1/4

|

7/8

|

10 1/2

|

1 1/2

|

|

6 — 1 1/4

|

3475

|

24 1/4

|

1

|

1 1/2

|

|||||||||

|

7 — 1 1/4

|

3550

|

24 1/2

|

1 1/8

|

1 1/2

|

|||||||||

|

20

|

22 1/2

|

8 — 1 3/8

|

4550

|

4700

|

27 1/4

|

24 1/4

|

20 1/4

|

6

|

3

|

1 1/4

|

1 1/4

|

11 5/8

|

1 5/8

|

|

24

|

26 1/2

|

6 — 1 1/2

|

6160

|

7255

|

31

|

28 5/8

|

24 1/4

|

7 3/16

|

3 5/8

|

1 1/2

|

1

|

14

|

1 13/16

|

|

7 — 1 1/2

|

7365

|

31 1/4

|

1 1/8

|

1 15/16

|

|||||||||

|

8 — 1 1/2

|

7500

|

31 5/8

|

1 1/4

|

2 1/16

|

|||||||||

|

9 — 1 1/2

|

7630

|

32 1/8

|

1 1/2

|

1 3/4

|

|||||||||

|

30

|

32 1/2

|

8 — 1 7/8

|

7290

|

12690

|

38 1/2

|

35 1/2

|

30 1/4

|

8 15/16

|

4 1/2

|

1 3/4

|

1 1/4

|

17 7/16

|

2 1/4

|

|

9 — 1 7/8

|

12990

|

39

|

1 1/2

|

2 7/16

|

|||||||||

|

10 — 1 7/8 |

13400

|

39 7/8

|

1 7/8

|

2 1/8

|

hbspt.forms.create({

portalId: “88145”,

formId: “387a2f0a-000b-4fec-ace9-674cd4cf472e”

});