Sweco Fab, Inc. designed and fabricated several steam drums for the Melamine Project at Donaldsonville, Louisiana.

Want to learn more about our products? Visit our webinar archives today!

Resources

Sweco Fab, Inc. designed and fabricated several steam drums for the Melamine Project at Donaldsonville, Louisiana.

Want to learn more about our products? Visit our webinar archives today!

Pictured above is a deaerator built by Sweco Fab, Inc. and is destined to go into service for one of the larger chemical companies at their Plaquemine, Louisiana Fields.

The upper vessel shown is a 120” diameter 304L stainless unit connected to a 144” carbon steel storage tank of approximately 38,000 lb.

Do you require a tank or vessel for an upcoming project? Let us price it for you today!

Sweco Fab, Inc. designed and fabricated a complete duct system for a major engineering and construction firm in Houston.The project is a carbon dioxide facility for a food processing plant being constructed in Massachusetts.

Two unique features of the 96” ID fabrication are the very light materials with close tolerances and the painting system for food grade product.

Do you have a need for a duct system? Get pricing on a duct system today!

Pictured above are Big-Ton Spring Supports specially designed by Piping Technology & Products, Inc. These types of supports are used in supporting large and heavy units such as compressors, vessels and pumps in power and petrochemical plants. The ones below were used to support vessels in excess of 120,000 pounds. The Big-Ton Spring Support are designed to allow limited movement in confined areas. By doing this, it saves the customer from having to entirely redesign the piping system and saves thousands of dollars.

Do you need a big ton for one of your upcoming projects. Let us price one for you today!

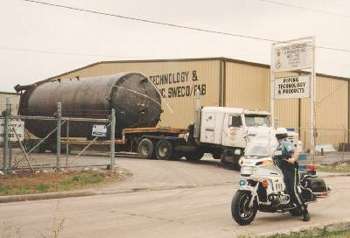

The picture above shows two views of launcher-receivers loaded on a truck. These devices are installed in pipelines to launch and receive pipeline pigs. Pigs can be used for cleaning or for separation of two products in the same pipeline. Modern pigs with sensing devices are used in old pipelines to look for damage or corrosion problems. These launcher-receivers part of several being built by the SWECO Fab, Inc. division of Piping Technology & Products, Inc. for a large MTBE plant in Saudi Arabia.

In need of some pig launchers and receivers for an upcoming project? Let us price one for you today!

The photograph above shows a computer-controlled bank of gas torches used to burn patterns of small components from large metal plates. The geometry of the components is used to program the computer. The metal plate is on a “water table” which catches the melted material to be utilized in the national program to conserve natural resources.

Piping Technology & Products, Inc. supplies hardware, pipe supports, expansion joints and other fabricated items for petrochemical, paper and electric power plants throughout the U.S. and overseas.

Want to learn more about our various products? Visit our webinar archives today!

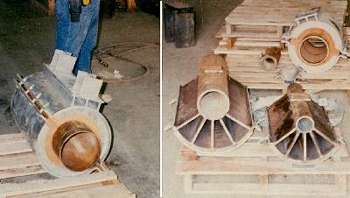

Sweco Fab, Inc., a wholly subsidiary of Piping Technology & Products, Inc., and an ASME and API code vessel shop recently unveiled their design of a wet air fan cyclone for a new high density polyethylene project.

The barrel, which is a twenty-one feet long, tapers upward from a twelve-inch diameter base to a six foot diameter top. Ears on the exterior of the barrel are provided for support and alignment. Air inlet is designed to mate with other components forming part of the process equipment. The fan cowling has outboard ears to facilitate ease of test, assembly and maintenance. The cyclone was rolled and formed from ¼ inch carbon steel and weighs 4,000 lb.

Want to learn more about Sweco Fab, Inc.? Visit out webinar archives!

The picture above shows special components of today’s piping systems. At the top are two rings with machined surfaces required to help seal the system when operating at high pressures. Rings and spacers can be fabricated from a variety of metals including carbon steels, stainless steels, alloys such as Inconel®, Hastelloy or Titanium. The choice of materials depends on the temperatures and pressures the system is designed for. Holes can be drilled to produce bleed rings which relieve pressure slowly. The above picture shows orifice plates which are made from the same materials.

Pictured above is one of the six identical tanks Sweco Fab, Inc. supplied for the expansion of City of Houston’s Sims Bayou Waste Treatment Plant.

These carbon steel tanks are rubber lined and have a special paint outside. Each tank has 6,000 gallon capacity.

Do you require ASME pressure vessels or tanks? Let us price them for you today!

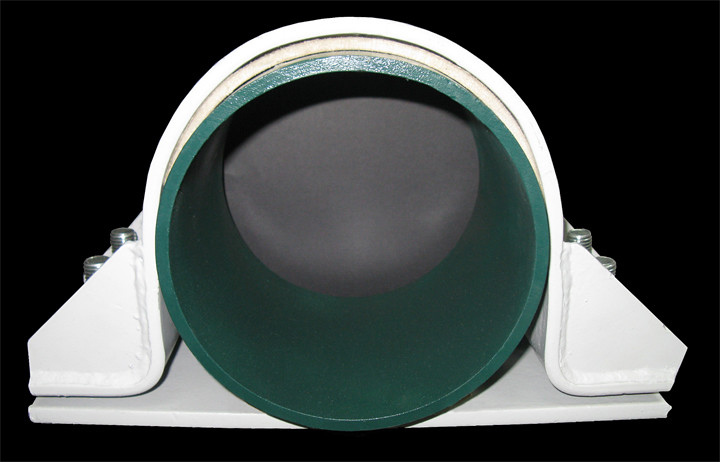

The photographs above show insulated pipe supports designed for a system being installed in a very cold climate in Russia. The insulating components are inside next to the pipe. The outside components are galvanized steel. In the foreground of the photo at the right are two fixtures which were built for load testing these pipe supports by applying known forces with a hydraulic load cell. Piping Technology & Products, Inc., fabricated prototype units for a Houston Engineering Firm and tested the units. After successful tests a number of similar units were built for shipment to Russia.

In need of some new insulated pipe supports? Let us price one for you today!

The photograph above shows a launcher-receiver designed to be installed in a six inch pipe to launch and receive pipeline pigs. Pigs can be used for cleaning or for separation of two products in the same pipeline. This launcher-receiver was one of two built by the SWECO Fab, Inc. division of Piping Technology & Products, Inc. for a major Gulf Coast Refinery.

Would you like to learn more about our pig launcher and receivers? Visit our webinar archives today!

The photograph above shows a surge protection vessel fabricated to ASME code specifications by Sweco Fab, Inc. This vessel was purchased by a major Houston E&C firm for export to an overseas project.

Do you require a tank or vessel for an upcoming project? Let us price it for you today!

The photograph above shows hydraulic snubbers which are used to protect critical components in refineries, power plants and other industrial systems from sudden movement by the attached piping system. Engineers specify these devices for systems which are subject to sudden accelerations caused by earthquakes, extreme wind loads or water hammer. The insert at the upper left shows eight snubbers, some are different sizes and six have dust covers to protect the piston seal. The snubber at the bottom has hardware attached so it is ready to be installed. Hydraulic snubbers resist sudden rapid movement of the pipe by limiting the flow rate of the fluid inside the snubber. The device is designed so slow movement, such as would be expected during thermal expansion, has practically no resistance, but sudden rapid movement is resisted with a force proportional to the velocity raised to a power, where the power is determined by the orifice valve and flow pattern in the design. Selection of materials and liquids used will depend on the environment where the snubber is installed.

Want to learn more about hydraulic snubbers? Visit our webinar archives!

The above photo shows an arrestor type hold down. This type of restraint is used when there is very low thermal movement. Its radius is lined with a belting material designed to absorb shock from movement. It is widely used on compressor lines or similar applications. The restraint type hold down’s clamp radius and base is lined with PT&P’s PTFE slide plate which allows for axial movement while restraining lateral movement and used on compressor lines where temperatures are high and thermal movement is great. This anchor type hold down is utilized on pipelines and require little or no insulation. It is fabricated from carbon steel and can be used in temperatures up to 750oF.

Would you like to learn more about hold down clamps and slide plates? Visit our website archives today!

Shown above is one of three neutralization tanks engineered and fabricated by Sweco Fab, Inc. This particular tank is being shipped to the paint contractor for painting and special interior coating.

These tanks are 12 feet in diameter, 39 feet 7 inches high, and have a storage capacity of 25,000 gallons. Special features requested by the client include clips welded on the interior for mounting of headers.

Do you require a tank or vessel for an upcoming project? Let us price it for you today!

Piping Technology & Products, Inc. announces the latest design of their “Horizontal Upthrust” base type constant support. The table or load flange move straight up or down as the weight of the pipe is transferred to the helical coil (spring) via the internal camlinkage. PTFE, 25% glass filled, slide bearings on the four corners eliminate the possibility of binding if undue axial or lateral forces are exerted. Also, PTFE, 25% glass filled, or graphite slide bearings can be added to the table to ease movement along the axis of the pipe. The Big-Ton and Type F Base Constant Supports are still available for other applications.]

Are you in need of constant supports? Receive a quote within 48 hours!

Piping Technology & Products, Inc. has designed and built thirty-two constant effort supports ranging in loads from eighty to eighty-seven kips with seven and one half inches of total travel on each.Six of the thirty-two are shown in position and they will support critical portions of the heater. The balance in other parts of the plant will support equally critical lines such as main steam and boiler reheat.

Located near Calvert, Texas, this is the second generating facility for Texas – New Mexico Power at this site. Piping Technology & Products, Inc. supplied the same material on the previous installation for this client.

Learn more about our constant supports, visit the webinar archive today!

Pictured above are spectacle blinds. Piping Technology & Products, Inc. builds these for any pipe size up to 60”. A variety of metals can be used including carbon steels, stainless steels or exotic alloys depending on the pressure rating required and the environment where they must function.

Do you need any spectacle blinds for an upcoming project? Let us price it for you today!

The photograph above shows one of 72 of these supports fabricated by Piping Technology & Products, Inc. for shipment to Alaska. Note that the distance between the top pipe where other components are attached and the base the support rests on can be changed by selecting the holes for the arms. These removable supports are used during installation of pipelines. Pipe sections may have other permanent supports if the pipe is above ground or the lines may be underground.

Would you like to learn more about pipe supports? Visit out webinar archives today!