Reliable Load Transfer Without Installation Headaches

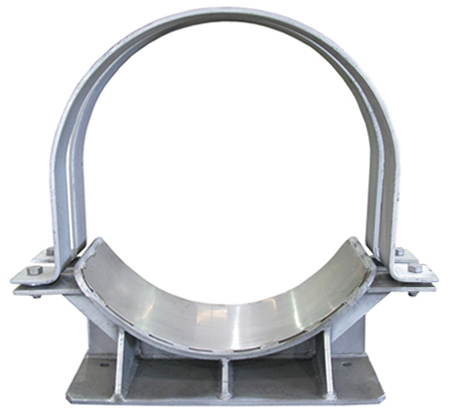

Pipe saddles are critical solutions for securing heavy pipelines and managing load transfer to structural elements. More than just supports, our engineered pipe saddles help reduce localized stress and maintain system alignment by stabilizing the pipe and minimizing deformation at critical support points.

What is a Pipe Saddle?

A pipe saddle consists of a curved base designed to partially wrap around a pipe, paired with a vertical stanchion that anchors it to a supporting structure. Pipe saddles are essential for:

- Managing high loads over long pipe spans.

- Preventing deformation, wear, and stress fractures.

- Ensuring system stability when support points are limited.

Piping Technology & Products manufactures pipe saddles to exact specifications using durable materials such as carbon steel, with options for specialized coatings to resist corrosion. Whether you need a standard design or a custom configuration, we deliver saddle supports built for your project’s diameter, load, and structural interface requirements.

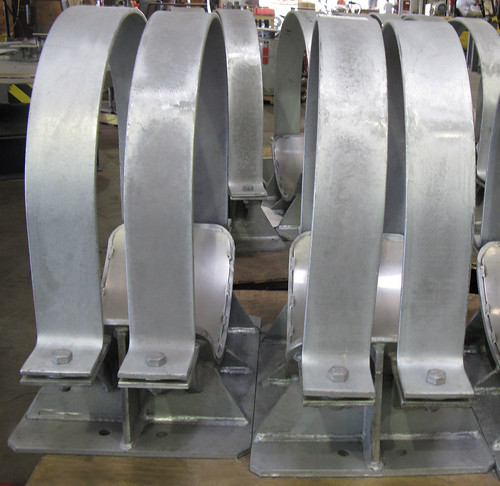

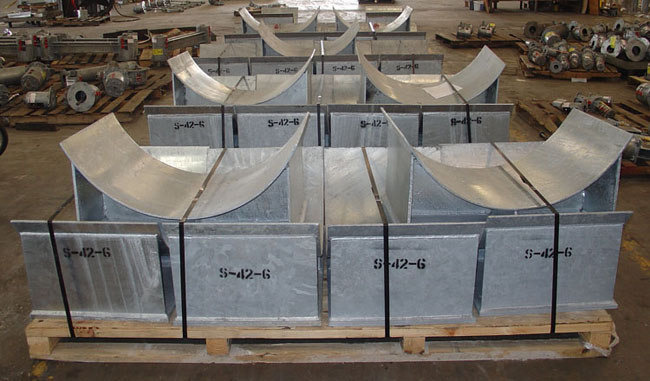

Case Study: Custom Pipe Saddles for a Midstream Gas Facility

For a midstream natural gas project in the Midwest, Piping Technology designed and delivered a large order of custom-fabricated pipe saddles:

- Pipe Size: 36-inch diameter.

- Load Requirements: Engineered for substantial dynamic loads.

- Finish: Hot-dip galvanized for long-term outdoor durability.

- Compliance: Designed to meet ASME standards.

Our in-house engineering team worked directly with the EPC contractor to accelerate the design and fabrication cycle. This proactive collaboration ensured a perfect field fit, eliminated rework, and helped keep the overall project on schedule, addressing a key priority for EPC managers while avoiding any installation setbacks.

Designed for Midstream Energy Demands

In the midstream oil and gas sector, performance, quality, and reliability are non-negotiable. Piping systems must withstand:

- Thermal expansion and contraction across long distances.

- Environmental exposure to moisture, temperature fluctuations, and corrosive agents.

- Variable load conditions over the system’s operational lifespan.

Our pipe saddles deliver the durability and stability midstream operators require, minimizing downtime risks and safeguarding critical infrastructure.

Additional Solutions for Midstream Applications

In addition to heavy-duty saddles, PT&P offers a full range of custom supports engineered for the challenges of midstream energy projects:

- Constant and Variable Spring Hangers: Manage vertical movement due to thermal expansion.

- Pipe Shoes

- Pipe Anchors and Guides: Control axial loads and direct pipe movement safely.

- Cryogenic Insulated Supports: Specialized designs for LNG and low-temperature systems.

- Custom U-bolts and Clamps: Engineered fastening solutions for complex configurations.

Each product is manufactured to meet project-specific load, movement, and environmental requirements, ensuring seamless system integration.

Why Project Managers Trust Piping Technology

When you partner with us, you get more than just products; you gain a reliable team committed to helping you deliver flawless projects.

We offer:

- Engineering Expertise: Real-time collaboration with seasoned engineers.

- Proven Product Quality: Materials and manufacturing processes that meet or exceed ASME, ASTM, and API standards.

- Manufacturing: Deep manufacturing expertise to deliver scale, large volume, fastest time to market customized solutions with a sharp focus on constructability and site needs.

- On-Time Delivery: A proven track record of meeting tight project timelines.

- Cost Efficiency: Competitive pricing without compromising quality or performance.

- Responsive Support: Fast answers to RFIs, urgent field issues, and design changes.

For Project Managers, that means reduced risk, minimized rework, and higher confidence in project success.

Get the Right Saddle Support for Your Next Project

Talk to an engineer today to discuss your application and receive a custom solution for your project needs.

Talk to an engineer today or Request a Quote