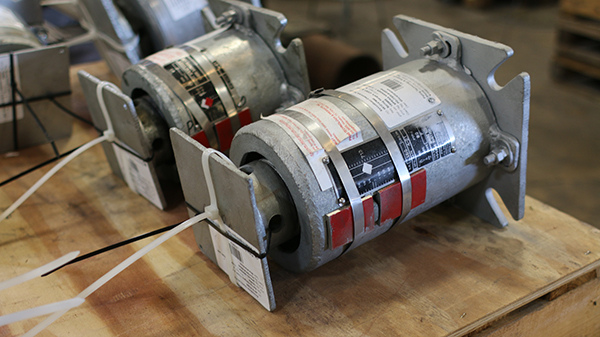

PT&P designed Fig. PTP 200-U upthrust constant spring supports modified to accommodate an increased installed height. PT&P fabricated these constant assemblies from A36 carbon steel. They were designed for temperatures up to 185°F, and a load of 15,737 lb. The constants are capable of a downward total travel of 2″ and are 61″ L x 25″ W x 39″ H. Standard load and travel tests were conducted prior to shipment.

When it comes to supporting piping and related components that experience significant vertical movement, constant spring supports are the go-to solution. These specialized supports are designed to keep the load consistent throughout the full range of movement, eliminating any significant deviations. But what makes them indispensable for industrial applications? Let’s break it down.

What Are Constant Spring Supports?

Constant springs maintain a steady supporting force as pipes expand and contract due to temperature changes. They come in horizontal or vertical designs and can be customized to handle various loads, movements, and configurations. Their ability to adapt to dynamic conditions ensures the integrity and efficiency of piping systems across diverse industries.

Key Benefits of Constant Spring Supports

- Manage Pipe Movement: Handle changes in pipe position caused by temperature fluctuations.

- Maintain Alignment: Prevent misalignment, ensuring pipes stay in proper positions.

- Reduce Thermal Stress: Minimize stress caused by thermal expansion and contraction.

- Adapt to Variable Loads: Provide reliable support in changing conditions.

- Versatility: Perfect for both high-temperature and cryogenic systems.

Constant spring supports find their way into a wide range of applications, including:

- Piping Systems: Essential in refineries, power plants, and chemical processing facilities.

- HVAC Systems: Support ducts in heating, ventilation, and air conditioning systems.

- Steam Systems: Ensure proper alignment in steam piping for manufacturing and power generation.

- Oil and Gas Pipelines: Compensate for temperature changes over long distances.

- Process Equipment: Safeguard reactors, heat exchangers, and vessels from stress-induced damage.

- Rotating Equipment: Reduce stress on pumps and compressors by supporting connected piping, prolonging equipment life.

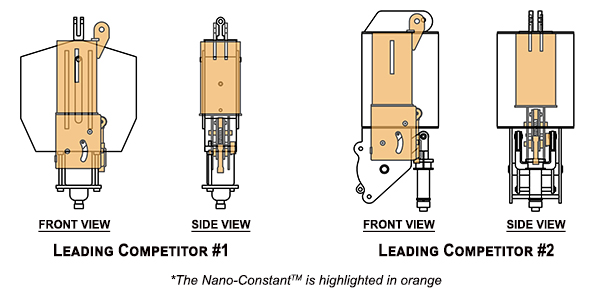

Spotlight on U-Type Constant Springs

U-Type constant springs are particularly popular for their ability to provide steady support to pipelines, ducts, and other structures experiencing thermal movement. These springs play a vital role in maintaining system integrity and preventing damage across various industrial settings.

From managing thermal expansion in pipelines to safeguarding critical equipment, constant spring supports are the unsung heroes of industrial operations. Their reliability and adaptability make them an invaluable asset across countless applications.

At our Houston-based facility, we design and manufacture constant spring supports with unmatched speed and precision. Operating 24/7, we are equipped to handle both small emergency orders and large-scale production needs. Our expertise spans industries like energy, oil & gas, petrochemicals, manufacturing, and more—delivering solutions globally. Our wide range of industry expertise demonstrates our unique ability to provide solutions across the globe in every sector we serve.

PT&P REF. ORIGINAL POST 03242015

Read More