Sweco Fab., Inc. designed and fabricated pig (pipeline intervention gadget) launchers and receivers with closures for a crude export pipeline in Mexico. Pig Launchers and receivers are pressure-containing vessels or sections of piping within a pipeline system that are utilized for pipeline maintenance, cleaning, and inline inspection for upstream, downstream, and midstream operations. The design of the launcher and receiver depends on the pig and pipeline design conditions. Crude oil, wet gas, dry gas, and product lines are typically cleaned with pipeline pigs monthly or semi-annually.

These units were custom-designed per ASME CODE B31.3 and weighed 2,400 lb. They are 120″ in length and have 12″ dia. minor barrels and 18″ dia. major barrels. The barrels are fabricated from API 5L Gr. B pipe, the flanges from SA105, and the closures are manufactured from carbon steel. The launchers are designed for operating temperatures ranging from -20°F to 212°F at 943 psig. They were radiography-tested and hydro-tested on-site at our manufacturing facility at 1,415 psig for two hours.

PT&P REF. ORIGINAL POST 02212014

Read More

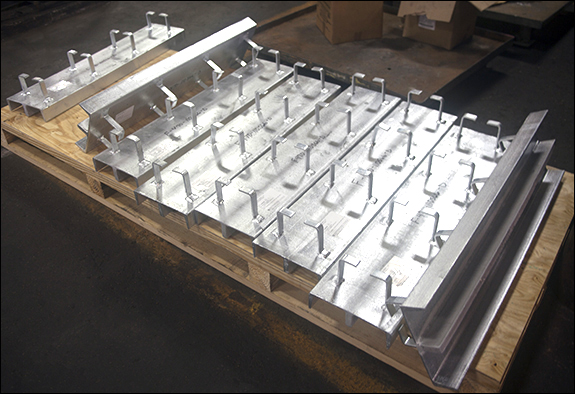

Within these cooling towers, screen guides are used in a gravity-flow distribution system where supply water flows or cascades down over successive offset levels of horizontal screens or splash bars into a basin. These guides provide a means by which screens or splash bars are supported from a concrete structure. The screens are intended to lower the temperature of water by causing the water to spread over large areas to promote maximum exposure to airflow as it cascades from the top of the tower into the lower basin. One side of the guide provides a “slot” by which screens or other types of “surfaces” can be installed. The other side of the guides are fitted with bent “strip anchor bars” similar to those used for embed plates. As a manufacturer of embed plates, we also supply these for mining facilities, semiconductor plants, wastewater treatment plants, or any construction site where there is steel attached to a concrete panel or slab.

Within these cooling towers, screen guides are used in a gravity-flow distribution system where supply water flows or cascades down over successive offset levels of horizontal screens or splash bars into a basin. These guides provide a means by which screens or splash bars are supported from a concrete structure. The screens are intended to lower the temperature of water by causing the water to spread over large areas to promote maximum exposure to airflow as it cascades from the top of the tower into the lower basin. One side of the guide provides a “slot” by which screens or other types of “surfaces” can be installed. The other side of the guides are fitted with bent “strip anchor bars” similar to those used for embed plates. As a manufacturer of embed plates, we also supply these for mining facilities, semiconductor plants, wastewater treatment plants, or any construction site where there is steel attached to a concrete panel or slab.