| Type: | Structural Support with Slide Plates |

| Size: | 1/2” x 5/18” |

| Material: | Carbon Steel | Hot-dipped Galvanized | Bronzphite® |

| Design: | 2,000 lb. Load | 730°F Temperature | 3,500 lb. Hydro-test |

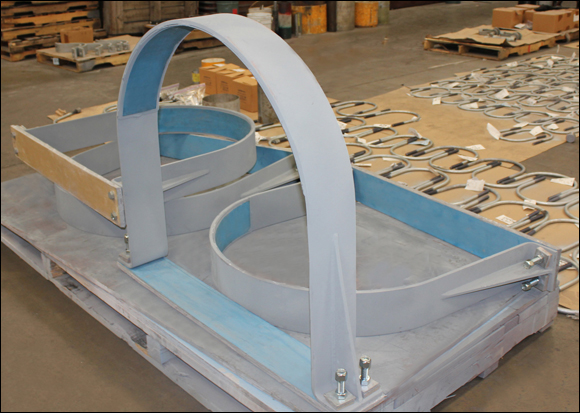

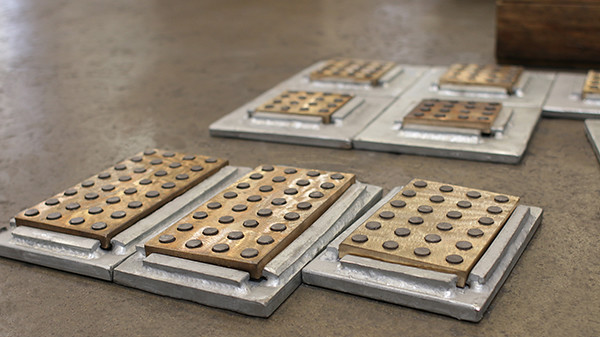

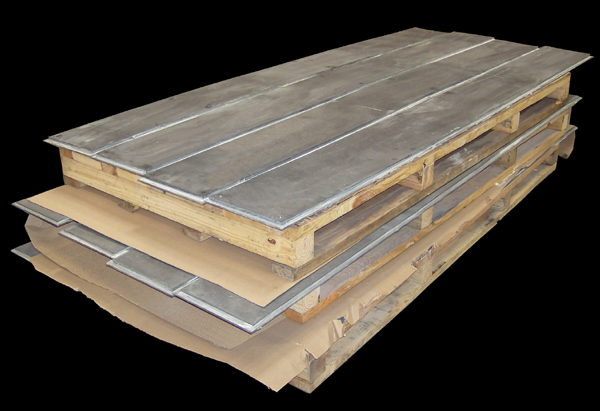

Piping Technology & Products, Inc. custom designed this structural support with Bronzphite® slide plates for an exhaust duct application at a fossil fuel-fired power plant in Louisiana. The Bronzphite measures 1/2” x 5″ x18” and was attached to a stand manufactured in carbon steel with a galvanized finish. The assembly is designed for an operating temperature of 730°F and an operating load of up to 2,000 lb. Also, designed with a hydro-test load of 3,500 lb. Standard visual and dimensional tests were performed prior to shipment.

Bronzphite® slide plates are commonly installed underneath the saddles of large stainless and carbon steel pressure vessels and tanks used in mining, refineries, and storage tanks storing a number of gasses such as chlorine, petroleum, and ammonia. Bronziphite plates used in these applications help to facilitate the growth of the tank due to pressure and temperature changes by lowering the friction between the supporting structural steel and the saddle of the vessel. Our Sweco division is ASME certified and can assist in the design and manufacture of small vessels and have experienced engineers utilizing materials such as Hastelloy, stainless, and carbon steel.

PT&P REF. ORIGINAL POST 02262019

Read More

Discover the secret to a lower coefficient of friction while permitting translational motion or movement with the supporting element. Learn about the different types of slide plates and pipe rollers used for various applications. View the design, load capabilities, and installation and maintenance guidelines for both slide plates and pipe rollers. See numerous photos featuring combinations with other critical pipe supports in order to allow for movement or a low coefficient of friction. Increase your understanding of the value added services that are offered by PT&P, and rest assured that your slide plate and pipe roller needs can be taken care of by our 24×7 web-based emergency services, field service, and quick-turn around time when you need it most.

Discover the secret to a lower coefficient of friction while permitting translational motion or movement with the supporting element. Learn about the different types of slide plates and pipe rollers used for various applications. View the design, load capabilities, and installation and maintenance guidelines for both slide plates and pipe rollers. See numerous photos featuring combinations with other critical pipe supports in order to allow for movement or a low coefficient of friction. Increase your understanding of the value added services that are offered by PT&P, and rest assured that your slide plate and pipe roller needs can be taken care of by our 24×7 web-based emergency services, field service, and quick-turn around time when you need it most.