|

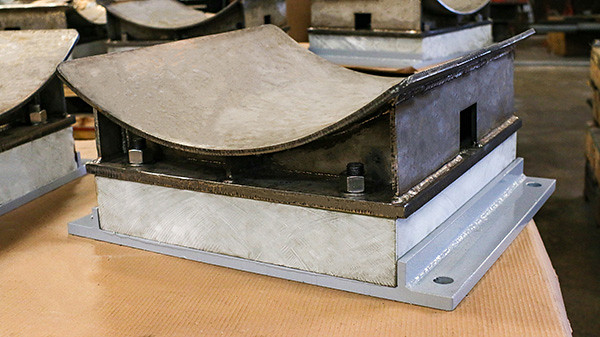

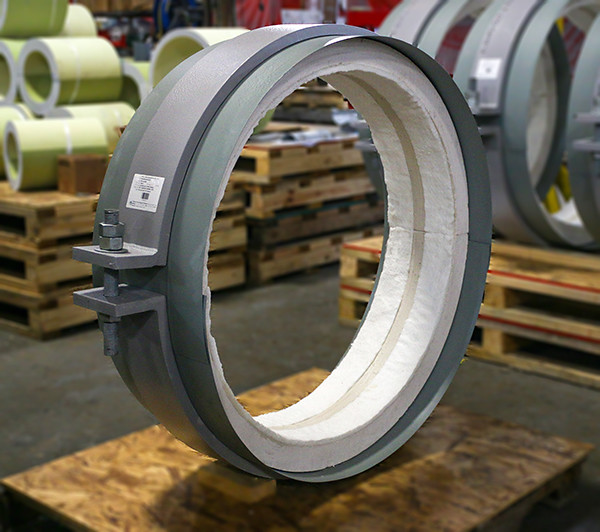

These cold shoe pre-insulated pipe supports were designed for a cryogenic pipeline at a petrochemical complex in Louisiana. These supports range in size from 46" to 52" in diameter and are engineered for temperatures as low as -20°F. The supports feature a dual-density polyurethane foam (PUF) insulation: the top portion has a density of 10 lb., while the bottom is 20 lb. high-density PUF. The shoe and bearing plates are constructed from carbon steel and finished with hot-dip galvanization for durability and corrosion protection. These cold shoes also include a vapor barrier, consisting of a three-layer lamination of polyester film and aluminum foil, ensuring effective insulation. Standard quality control tests were conducted on all units before shipment to ensure compliance with performance standards.

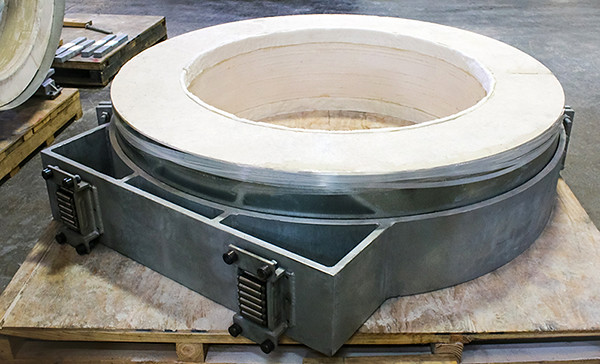

This type of cold shoe design is also utilized on liquefied natural gas (LNG) storage tanks. Liquefied Natural Gas (LNG) storage tanks are specialized containers designed to store LNG, which is natural gas that has been cooled to a liquid state at approximately -260°F (-162°C). This liquefaction process reduces the volume of the gas by about 600 times, making it much more efficient to store and transport. Most LNG tanks are double-walled with an inner and outer shell. The inner shell, typically made of stainless steel or nickel alloy, contains the LNG, while the outer shell, often made of carbon steel or concrete, provides structural support and can store up to 200,000 cubic meters or more.

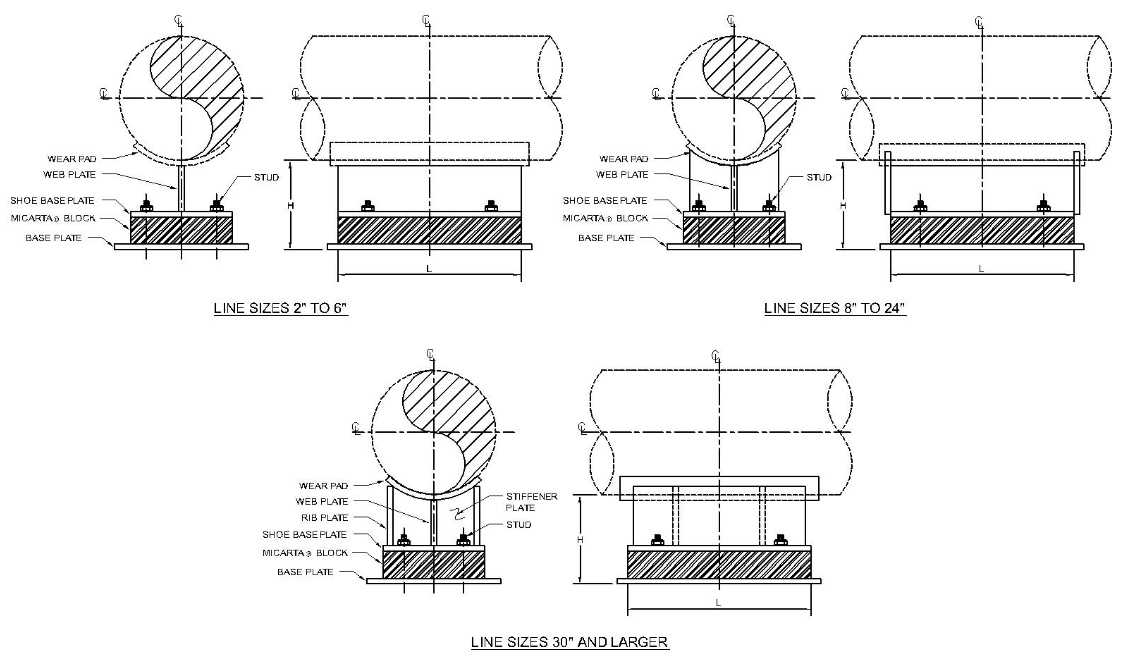

Our pre-insulated pipe support portfolio is the most complete in terms of the types of insulation we work with and the industries we serve. We design and manufacture supports with:

- Permali (Cold Shoe) – Temperature range: Ambient to -300°F – Compressive strength: 22,000 PSI – Tensile strength: 28,000 PSI **

- Micarta (Cold Shoe) – Temperature range: Ambient to -300°F – Compressive strength: 39,000 PSI – Tensile strength: 12,000 PSI **

- Polyurethane (Cold Shoe) – Temperature range: Ambient to -300°F – Compressive strength: 200 PSI to 911 PSI (dependent on density) – Tensile strength: 12,000 PSI

- Foam Glass (Cold or Hot Shoe)** – Temperature range: -450°F to 1,000°F – Compressive strength: 100 PSI – Tensile strength: 50 PSI

- Marinite (Hot Shoe) – Temperature range: Ambient to 1,200°F – Compressive strength: 2,000 PSI – Tensile strength: 500 PSI **F. Calcium Silicate (Hot Shoe)** – Temperature range: Ambient to 1,200°F – Compressive strength: 160 PSI – Tensile strength: 50 PSI

The supports can be manufactured with carbon steel or stainless or the material the project may require. The thrush plates can be hastelloy, inconel, etc depending on the pipe material. Working with different metallurgies is a part of standard manufacturing protocols.

These supports are deployed in semiconductor, petrochemical, nuclear, blue hydrogen, blue ammonia, solar, LNG, pharma, data centers, automotive, mines, pulp/paper, building materials, food processing and EV battery plants.

PT&P REF. ORIGINAL POST 03282017

This webinar will give you an introduction to Pipe Shields, Inc. and its unique line of pre-insulated pipe supports, slides, guides and anchors that it developed and patented over it’s 40 year history. It will cover various designs, commercial applications (chilled and heated water lines, HVAC systems and low pressure steam lines), installation and maintenance procedures and the benefits of using pre-insulated pipe supports (vs. doing insulation in the field). This webinar will be delivered by Albert Dizon, General Manager of Pipe Shields, who has been working with pre-insulated pipe supports for 30+ years. Join us and receive some of his experience and wisdom!

This webinar will give you an introduction to Pipe Shields, Inc. and its unique line of pre-insulated pipe supports, slides, guides and anchors that it developed and patented over it’s 40 year history. It will cover various designs, commercial applications (chilled and heated water lines, HVAC systems and low pressure steam lines), installation and maintenance procedures and the benefits of using pre-insulated pipe supports (vs. doing insulation in the field). This webinar will be delivered by Albert Dizon, General Manager of Pipe Shields, who has been working with pre-insulated pipe supports for 30+ years. Join us and receive some of his experience and wisdom!