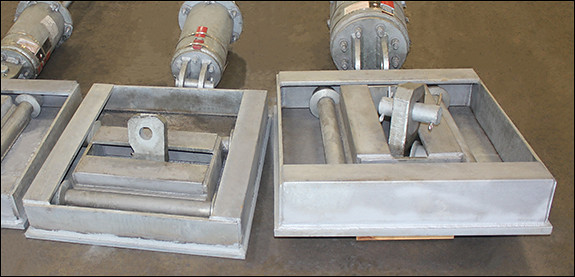

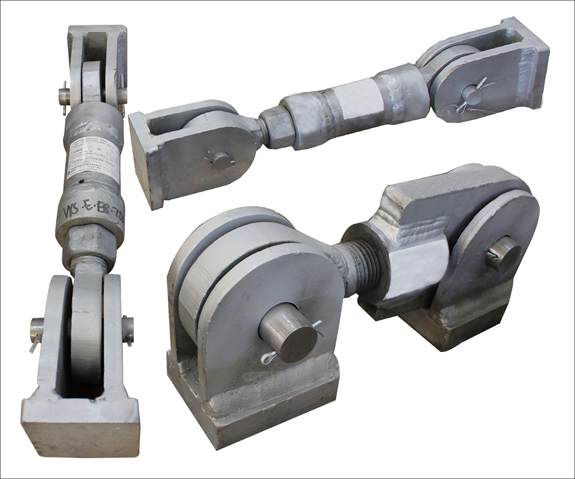

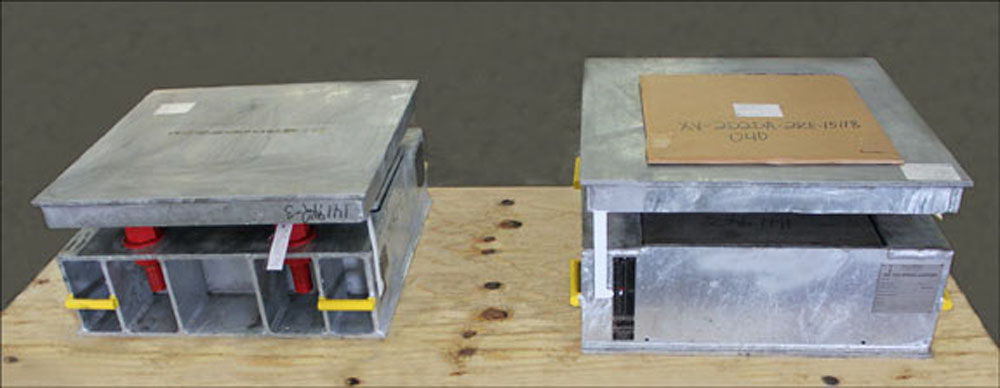

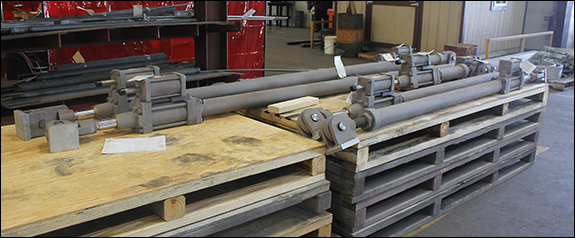

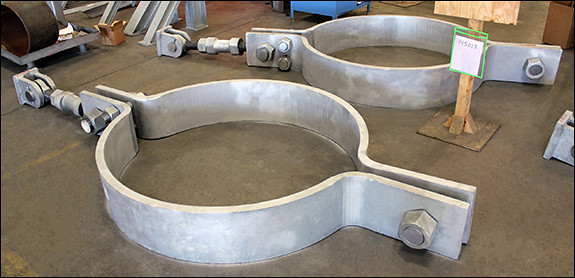

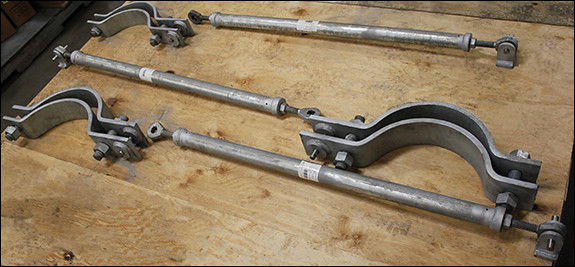

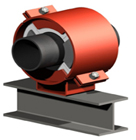

| Type: | Variables with dual travelers |

| Design: | Operating load: 1,698-21,756 lbs |

| Material: | A36 Carbon Steel with HDG finish |

| Size: | Horizontal Travelers range from size 2 to size 4 |

These dual travelers with Type-C variable spring hanger assemblies were custom designed by Piping Technology & Products for valves in a de-coker unit in Texas. All completed assemblies were fabricated from A36 carbon steel with an HDG finish. The travelers range from size 2 to size 4 and are designed for 12″ of horizontal movement. The variables are designed for an operating loads ranging from 1,698-21,756 lbs.

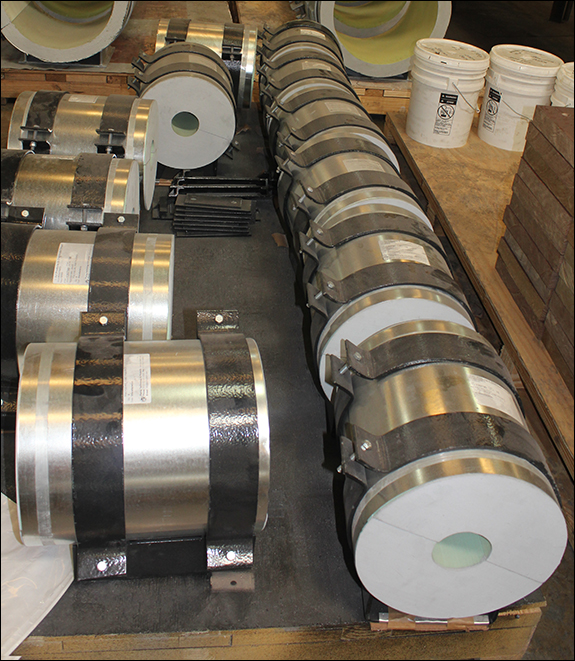

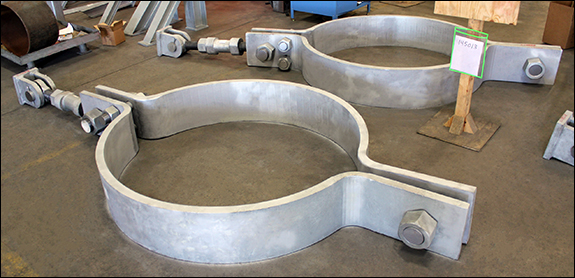

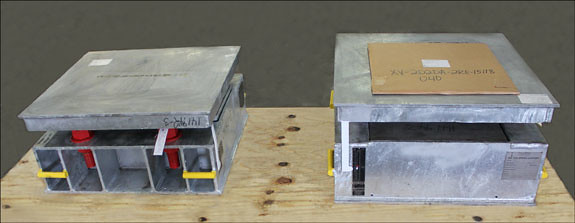

This webinar will give you an introduction to Pipe Shields, Inc. and its unique line of pre-insulated pipe supports, slides, guides and anchors that it developed and patented over it’s 40 year history. It will cover various designs, commercial applications (chilled and heated water lines, HVAC systems and low pressure steam lines), installation and maintenance procedures and the benefits of using pre-insulated pipe supports (vs. doing insulation in the field). This webinar will be delivered by Albert Dizon, General Manager of Pipe Shields, who has been working with pre-insulated pipe supports for 30+ years. Join us and receive some of his experience and wisdom!

This webinar will give you an introduction to Pipe Shields, Inc. and its unique line of pre-insulated pipe supports, slides, guides and anchors that it developed and patented over it’s 40 year history. It will cover various designs, commercial applications (chilled and heated water lines, HVAC systems and low pressure steam lines), installation and maintenance procedures and the benefits of using pre-insulated pipe supports (vs. doing insulation in the field). This webinar will be delivered by Albert Dizon, General Manager of Pipe Shields, who has been working with pre-insulated pipe supports for 30+ years. Join us and receive some of his experience and wisdom!