Insulated Pipe Supports for Low Temperatures

PT&P manufactured cryogenic pipe saddles for LNG transportation pipelines. These types of insulated supports have been utilized in LNG plants around the world. Insulated supports are also used on cold piping in semiconductor plants or plants that make batteries to eliminate condensation.

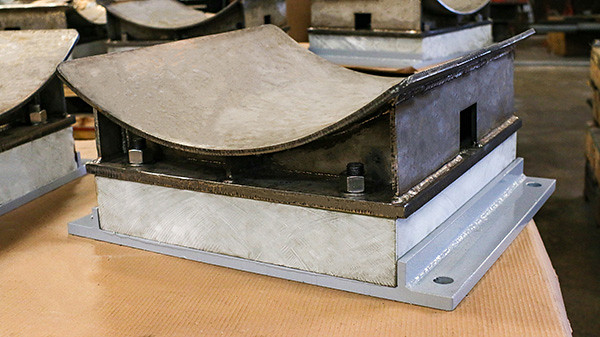

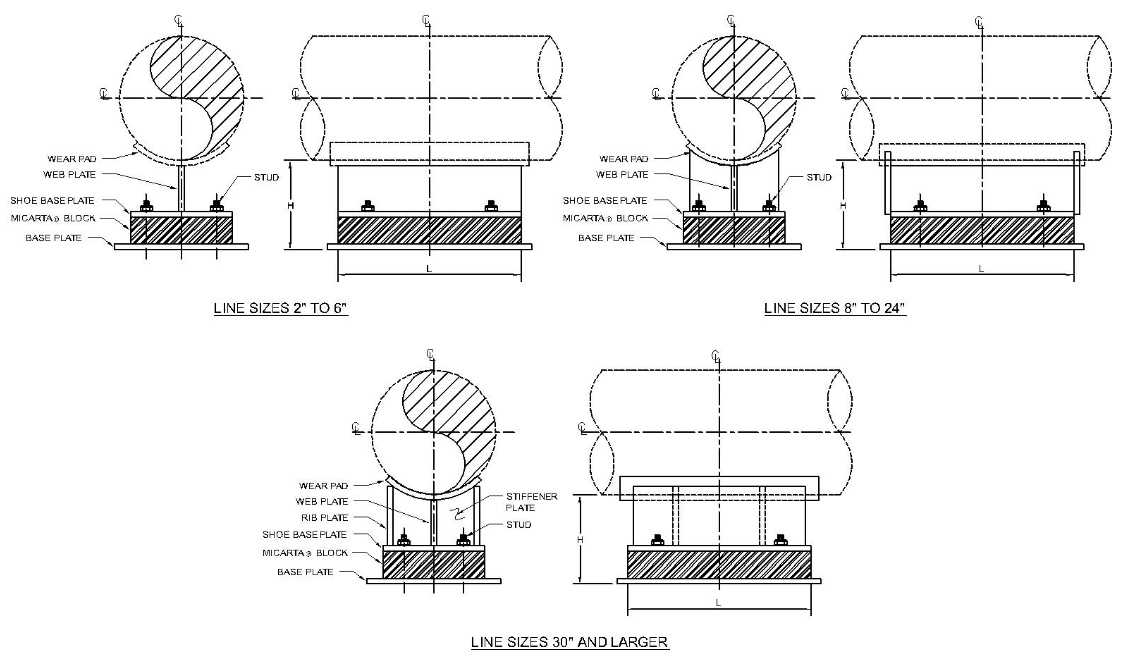

A cold shoe is a pipe support used for cryogenic applications where the transfer of cold temps from the pipeline to the surrounding steel pipe rack is not desirable. These supports can be used for temperatures down to -320° Fahrenheit. This particular type of insulated pipe saddle assembly was fabricated with a carbon steel base plate, 304L stainless steel saddle, and an insulation block. The overall size ranges from 25” x 19” x 12-¾” to 29” x 25” x 13-3/8”. These pipe shoes were manufactured to support pipe sizes ranging in diameter from 36″ to 42″ NPS.

For additional information about Insulated Pipe Supports go to our product page.

Cryogenic Pipe Saddles Made for LNG Project

For this job, our client was a new entrant into the LNG engineering and design market space, and this was one of their capstone projects internally and for the marketplace. Given PTP’s long history and experience concerning LNG pipe supports, we served as strategic partners in the engagement. We identified that the client was using a pre-existing standard that underestimated the amount of Micarta® insulation thickness needed to provide adequate insulation for the facility.

PT&P engineers recognized that the insulation was not sufficient, and we tested the existing design using a test fixture we developed to demonstrate our concern. PT&P utilized thermal scanning (infrared technology) to measure temperature at various locations around the insulated pipe support. As a result of our tests, our client corrected the concern, saving dollars, man hours, and scheduled project completion.

Our work with facilities such as these are a great example of our commitment to providing clean, affordable energy to the world.

To find additional information about our Cryogenic Pipe Saddles visit our product page.

PT&P REF. ORIGINAL POST 03092021