Tag: Constant Spring Supports

Constant Spring Supports Product Video

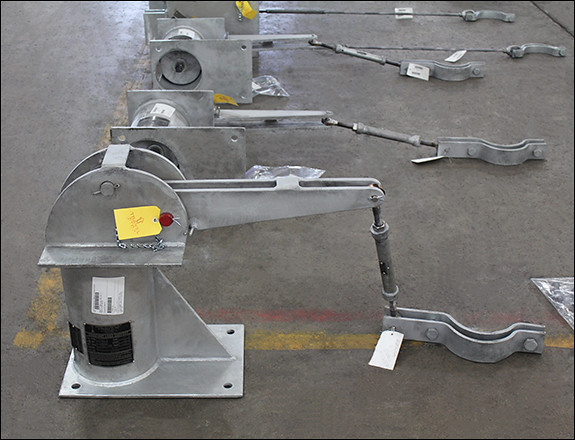

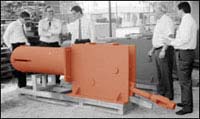

C-Type Constant Spring Supports for a Refinery in Texas

| Type: | Constant Spring Supports |

| Size: | 25″ in Height x 17-38″ in Length x 11-5/8″ in Width |

| Material: | A-36 Carbon Steel with HDG Finish |

| Design: | 981 lb. to 1828 lb. load | 2-1/2″ to 3″ Vertical Movement Range |

| Testing: | Standard Load and Travel Testing per MSS Standards |

Piping Technology & Products, Inc. designed and manufactured C-type constant spring support assemblies for a refinery in Texas. The constants are 25″ in height, 17-3/8″ in length, and 11-5/8″ in width. Their load capacities range from 981 lb. to 1828 lb., with a vertical movement ranging from 2-1/2″ to 3″. All constants were fabricated from A-36 carbon steel with a hot-dipped galvanized finish, and underwent standard load and travel testing per MSS Standards prior to shipment.

Constant Spring Supports Design and Application Webinar

This webinar is over, view the recording in the webinar archives

This Webinar will focus on the different types of constant spring supports. Learn about the special features available, in addition to the design of a constant support. View how the different cam/coil configurations produce a unique response to an applied load. Discover the step by step process used to size a spring for your application. Learn about the different attachments, testing, and installation and maintenance procedures. View examples of failed supports provided by our Field Service Division and learn why they failed and how to prevent it. Gain knowledge of the valuable tips used when deciding to adjust or replace a constant spring support, as well as shutdown and isolation procedures.

The featured presenter, Jerry Godina has over 15 years experience as a pipe support designer and manages PT&P’s engineer training development program. He also inspects existing supports, consults on site remediation projects and oversees installation on a regular basis.

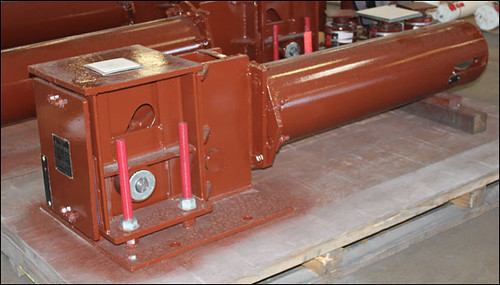

Constant Spring Supports Designed for a Power Plant in New Mexico

PT&P fabricated constant support assemblies for a power plant in New Mexico. The constant assemblies will be used in conjunction with structural supports also provided by PT&P. Operating loads range between 7,000 lb. and 20,000 lb. and designed for movements from 10-1/2″ to 12″. All thread rods were coated with rust prevention compound and the constants were painted with Intergard® 475 HSS. The travel stops are wired to the constants frame and can be reused to lock the constant, preventing travel during plant maintenance or shutdowns. Standard load and travel tests were completed according to MSS standards prior to shipment.

Custom F-Type Constant Spring Supports for Oil Refinery

PT&P designed 100-F type constant spring supports for an oil refinery in Alabama. These custom constant spring supports are 32” x 12” x 23.5” and designed to support an operating load of 650 lb. with 14” of total travel. The constants are fabricated from A36 carbon steel and the coil is from 5160H alloy material. Standard load and travel testing were completed to ensure the quality and performance of these constants.

Constant Spring Supports Designed for a Steam Methane Reformer

PT&P manufactured Fig. PTP 100-E constant spring supports for a steam methane reformer plant project in Thailand. The constant springs are designed for a pipe operating temperature from 650°F to 1250°F and an operating load of 3,355 lb. with a movement of 13″ upward. The constants are fabricated from carbon steel and painted with an epoxy for high temperatures. Standard load and travel test were completed prior to shipment.

Custom Designed Upthrust Constant Spring Supports

PT&P designed Fig. PTP 200-U upthrust constant spring supports modified to accommodate an increased installed height. PT&P fabricated these constant assemblies from A36 carbon steel. They were designed for temperatures up to 185°F, and a load of 15,737 lb. The constants are capable of a downward total travel of 2″ and are 61″ L x 25″ W x 39″ H. Standard load and travel tests were conducted prior to shipment.

B-Type Constant Spring Supports Designed for a Hydrocracker Application

PT&P manufactured B type constant spring supports for a hydrocracker application at a refinery in Port Author, TX. These custom designed constants are 83″ x 41″ x 20″, and designed to support a 53,000 lb. riser pipe through two trunnions. The constants are designed for an operating load of 26,700 lb. with 10-1/2″ of total travel. They are fabricated from A36 carbon steel and underwent standard load and travel testing prior to shipment.

U-Type Constant Spring Supports Designed to Support Ducts in an Acid Plant

U-Type constant spring supports were designed to support ducts in an acid plant. The constants are fabricated from carbon steel, galvanized and painted for extra protection against corrosion. The U-type constants are designed to support piping from below. The base plate is 25-7/8″ wide and bolted directly to the top of the steel or floor. The assemblies measure 84″ in length and 22-1/2″ in height. They only have vertical movement subjected by 6-1/2″ total upwards travel and are capable of supporting a 13,489 lb. load. The constants underwent standard spring testing prior to shipment.

G Type Constant Spring Supports Designed for a Power Plant in Mississippi

PT&P custom designed 16 G type constant spring supports for a power plant in Mississippi. The constants are comprised of two standard constant spring housing sub-assemblies joined together with an intermediate bridge assembly. They also include welded beam attachments, rods and hex nuts. The assemblies are designed to support pipes ranging from 80″ – 96″ in diameter. Standard load and travel tests were performed prior to shipment.

100-B Type Constant Spring Supports Designed with Double Transverse Lugs for a Refinery in Mexico

These 100-B Type vertical constant spring supports were designed with double transverse lugs for a refinery in Mexico. The constants were fabricated from A-36 carbon steel and they range in size from 23-1/4″ to 26-5/8″ in height, 50″ to 78″ in length and 18-3/8″ to 18-3/4″ in width. They are designed for operating loads ranging from 8,000 – 27,000 lb. and upward movements ranging from 3″ to 7″. The double transverse lugs allow the entire constant to swivel with the rod. Standard load and travel tests were performed prior to shipment.

Stainless Steel Constant Spring Supports for an Oil Refinery in the Virgin Islands

PT&P custom designed C-type constant spring supports for an oil refinery in the Virgin Islands. They are fabricated entirely from 304 stainless steel to support piping in a highly corrosive environment. The design loads are 7,000 lb., 9,500 lb., and 11,000 lb. with movements of 2-1/2″ and 3″. The constants measure 29″ L x 22″ W x 20″ H. Standard load and travel testing was conducted prior to shipment.

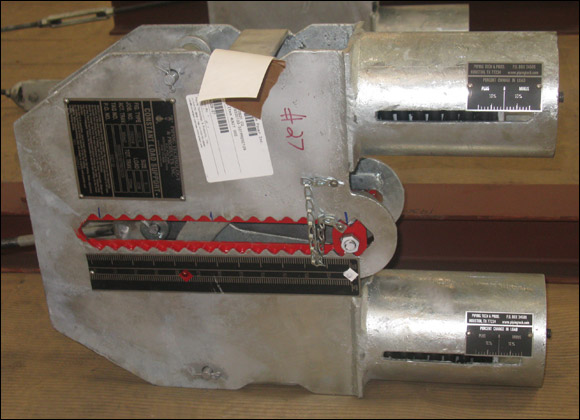

Over 40 Constant Spring Supports Designed to Support Production Pipes

Over 40 constant spring supports were custom designed to support production pipes in an oil refinery. This picture shows a Fig. 200 U-Type constant spring support.

This picture shows a Fig. 100 B-Type constant spring support.

The constants range in size from 22″ to 30″ in height, 35″ to 85″ in length, and 12″ to 31″ in width. Their load capacities range from 1,800 lb. to 20,800 lb. with a vertical movement ranging from 7″ to 11-1/2″. All constants were fabricated from A-36 carbon steel and painted with a 3-coat paint system. Each constant went through standard load and travel testing per MSS Standards prior to shipment.

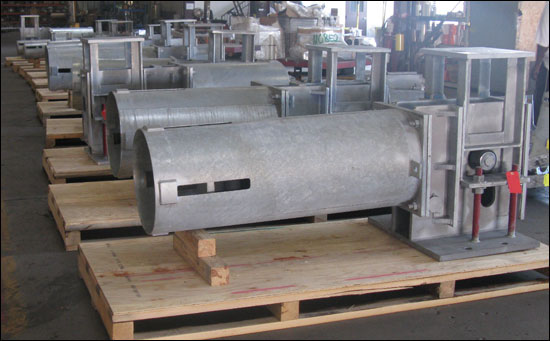

200 E-Type Horizontal Constant Spring Supports for a Fired Heater Radiant Manifold

These 200 E-Type horizontal constant spring supports are fabricated from A-36 carbon steel with a hot-dipped galvanize finish. The pins made for constants operation are A-322-4140 high strength carbon steel. The constants range in size from 22-3/4″ to 26-1/4″ heights, 60″ to 90″ lengths, 18″ width, and 19-1/2″ to 23-1/2″ in coil housing diameters. They are designed for 23,160 lb. to 33,700 lb. loads and 6-1/2″ to 14″ of total travel. A total of sixteen assemblies were custom designed for a fired heater radiant manifold. Each pipe hanger assembly went through standard load and travel testing prior to shipping.

Special E-Type Constant Springs Designed to Support Boiler Trim Piping

Special PTP-100 E-Type constant spring supports were custom designed to support boiler trim piping for steam generating in an upper thermal power unit. The constants measure 5-3/8″ W x 16-3/4″ L x 23-1/2″ H. They are highly customized to meet the customer’s space requirements and operating method to eliminate the hanger rod from shifting, allowing it to move only vertically while going from cold to hot position. Standard constant assemblies of this size, are about 50% larger and the hanger rod would shift horizontally as the travel reaches the hot position. These constants are designed for loads ranging from 72 lb. to 92 lb. and movements ranging from 10″ to 11-1/2″ downward. Standard load and travel tests were conducted prior to shipment

Stock Upthrust Constants Modified with an Auxillary Platform

These 200 U-Type constant spring supports were modified to increase their installed height by adding a secondary plate and angles, which will be welded to the structural beam. The constants range in size from 25″ to 27″ in height, 52″ to 67″ in length, and 25″ in width. Their load capacities range from 10,300 lb. to 13,000 lb. with vertical movement ranging from 3″ to 4-1/2″. All constants were fabricated from A-36 carbon steel, and went through standard load and travel testing per MSS Standards prior to shipment.

Do you have a similar application that requires upthrust constants? Get pricing today!

U-Type Constant Springs Custom Designed for Large Travel for an Oil Refinery

These figure 200 U-type constant springs were fabricated from A-36 carbon steel and range in size from 30-1/2″ to 41″ in height, 25″ to 31″ in width, and 68″ to 80″ in length. These are horizontal constants designed to support piping from below where the base plate is bolted directly to the top of the steel or the foundation using anchor bolts. Loads range from 9,000 lb. to 42,000 lb., and vertical movements range from 6″ to 11″. All the constants went through standard load and travel testing per MSS Standards prior to shipment.

Want to learn more about constant springs? Instantly view a recording of a past webinar.

Constant Spring Supports Designed with Special Lugs for Connecting to a Trolley

These PT&P 200 series constants are fabricated from A36 carbon steel. The 200-A constants measure 18.5″w x 20″H x 65″L and will support a 22,200 lb. load. They are modified to avoid interference with the structure by shortening the frame. The 200-C constants measure 18.5″w x 29″H x 80″L and will support a 32,000 lb. load. The constants have specially fabricated lugs to allow for a 3 ton trolley to connect with it.

Do you have a need for constants in a current or upcoming project? Let us price them for you!

100-C Constant Spring Supports with Double Lug Suspension and Chained Travel Stops for an Oil Refinery in Canada

These figure 100 C-type constant springs were manufactured from A36 carbon steel for an oil refinery in Canada. Each constant was designed for 7″ of travel with a load of 35,144 lb. They measure 21.5″ W x 42″ L x 80″ H, and were specially designed to match a competitor’s dimensions in order to fit in the required application.

Do you require constant spring supports for your piping system? Get pricing today!