——————————————————————————————————————————

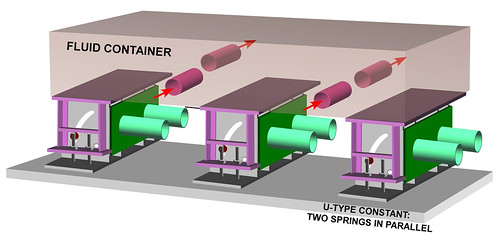

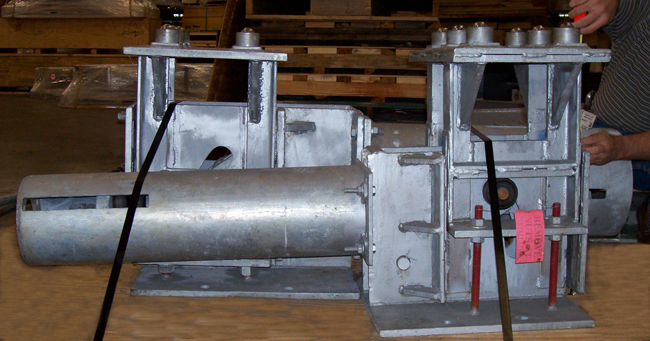

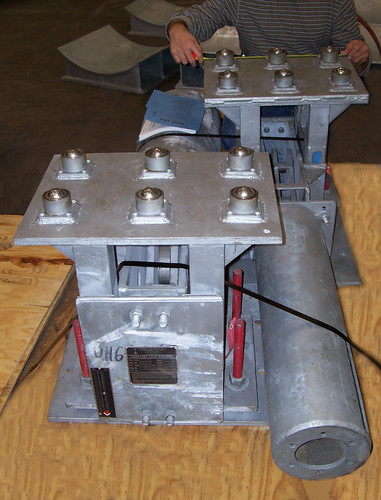

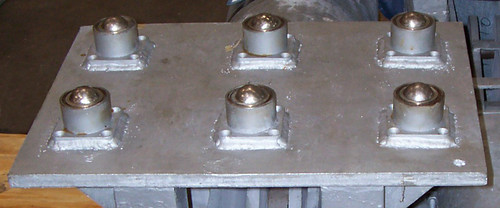

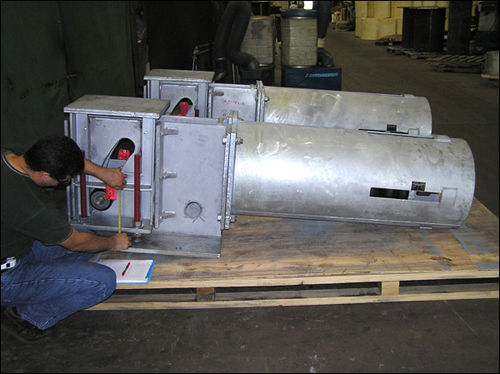

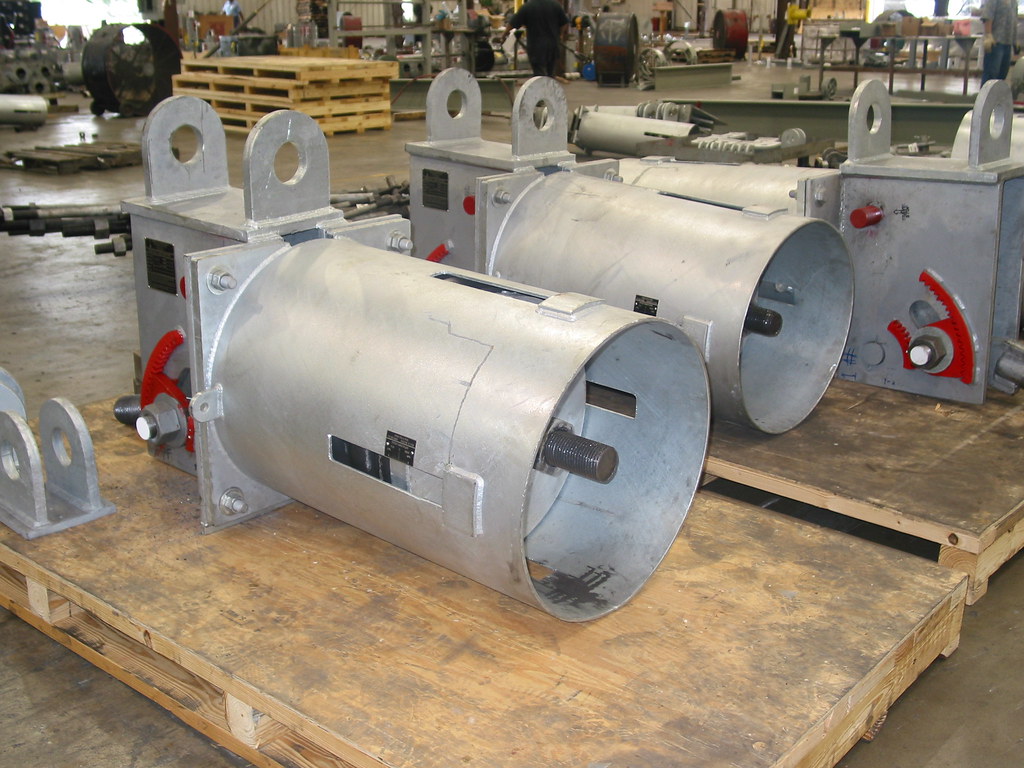

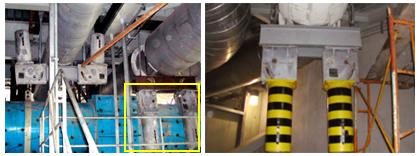

A “U-Type” and 6 “C-Type” constant spring supports were designed to support piping in a corrosive environment located off-shore in Malaysia. The U-Type measures 21″ x 25″ x 57″ and C-Types range in size from 11-5/8″ x 17″ x 4″ to 18-3/4″ x 32″ x 80″.

The constants are fabricated from A36 carbon steel with a fluorocarbon coating on the pins. The frame, housing, and all components were coated with a 3-coat paint system to resist corrosion. Standard load and travel tests were performed prior to shipping the constants on a rush basis.

Want to learn more about constant springs? Instantly view a past webinar on constants now!