Tag: gallery

June 6, 2018

Field Services – Pipe Supports

ASME / Misc. Fabrication

November 16, 2017

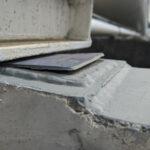

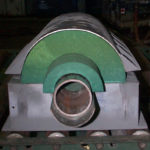

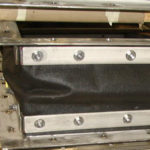

FRP Wear Pads

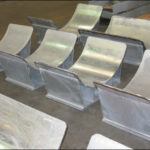

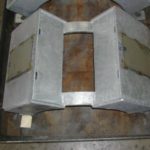

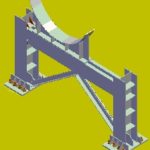

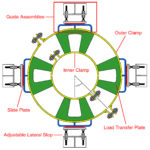

Pipe Shoes and Pipe Guides

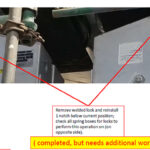

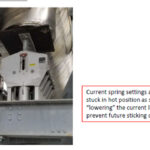

Snubbers Sway Braces Sway Struts

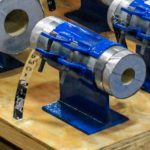

Hydraulic Snubbers

Mechanical Snubbers

Sway Braces

Sway Struts

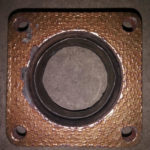

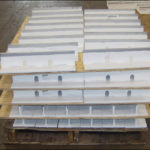

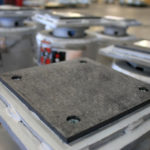

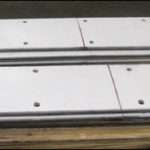

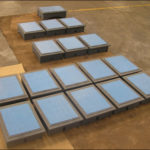

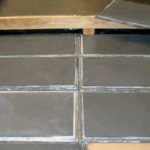

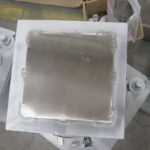

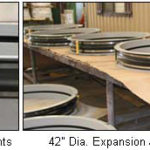

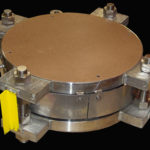

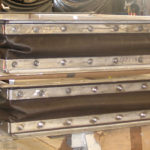

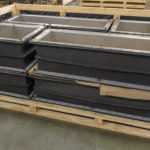

Slide Bearing Plates

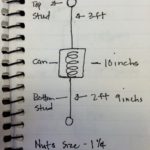

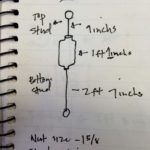

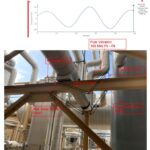

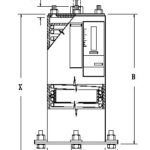

Engineered Spring Supports

Big Ton Spring Supports

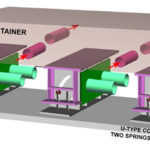

Compact Spring Supports

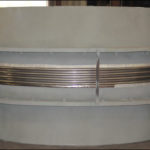

Constant Spring Supports

Variable Spring Supports

Instrument Stands & Supports

Floor Mounts

U-Bolt

Wall Mount

Pipe Support & Hangers

Beam Attachments

Clevis Hangers

Hardware, Rods, & U-Bolts

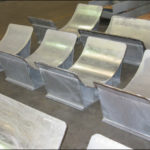

Hold-Down Pipe Clamps

Pipe Clamps & Risers

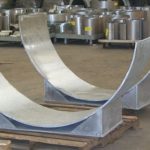

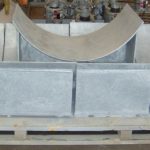

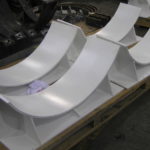

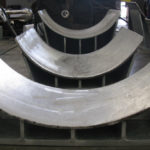

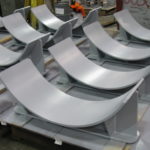

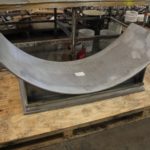

Pipe Saddles & Coverings

Pre-Insulated Pipe Supports

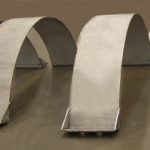

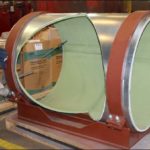

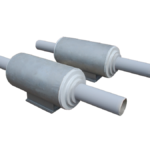

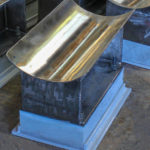

Cryogenic Pipe Supports (Cold Shoes)

High Temperature Supports (Hot Shoes)