| Type: | Pre-Insulated Pipe Supports “Hot Shoes” |

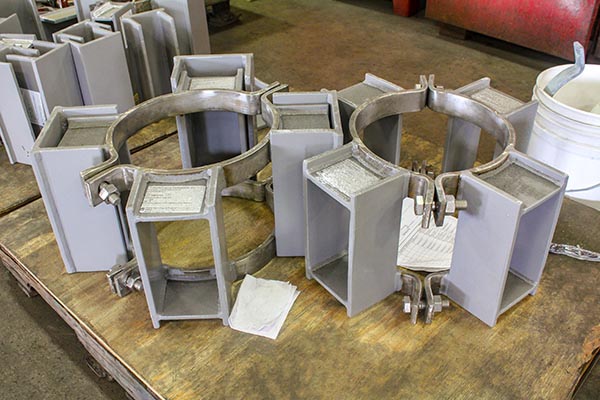

| Size: | 1″ to 3″ NPS | 1″ to 2″ Thick Insulation |

| Material: | HDG Carbon Steel | Calcium Silicate |

| Design: | Operating Temp.up to 1800°F Operating Loads up to 1000 lb. Movements of +/- 4-1/2″ |

| Testing: | Standard Q.C. Inspections |

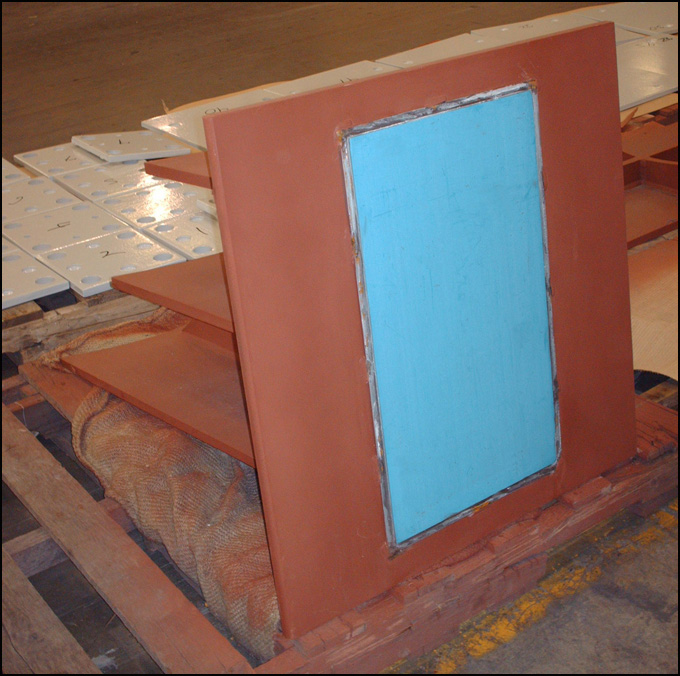

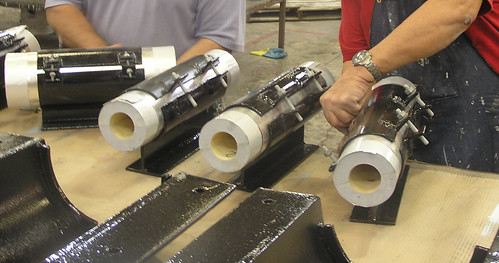

Pipe Shields, Inc., a division of PT&P, custom-designed insulated pipe supports for high temperatures in a chemical plant. These "hot shoes" are fabricated from A36 carbon steel and include a hot-dipped galvanized finish. They range in nominal pipe sizes from 1" to 3" and include 1"-2" thick calcium silicate insulation. The supports are designed for an operating temperature up to 1800°F and operating loads up to 1000 lb, with +/- 4 -1/2 movement. Quality control inspections were performed before shipping to Indiana.

Pipe Shields Inc. pioneered the design and manufacture of pre-insulated pipe supports, slides, guides and anchors and is a subsidiary of Piping Technology and Products, Inc. Our products are ubiquitous, serving diverse industries including hospitals, airports, semiconductor plants, automotive plants, EV battery plants, data centers, pharmaceutical plants, food processing, petrochemical plants, and power and renewable energy plants sometimes used in cold service lines and some dual temp lines between TCUs (temperature control units) and reactor jackets. Engineers often specify Pipe Shields and PT&P products as the foundation for designing various piping systems.

Last year we built over 50,000 units of this kind of support in our Houston-based manufacturing facility. We were the first in the industry to employ the use of high-speed manufacturing automation to facilitate the cutting of the high-density calcium silicate to meet tight deliveries required for the projects. The advent of computer-controlled cutting equipment has improved how we do things at PT&P. Integrating these advanced technologies has led to significant improvements in manufacturing processes, enabling unparalleled accuracy in cutting high-density insulation. Computer-controlled cutting equipment allows for intricate and complex designs that were once challenging or impossible to achieve manually. Automating cutting processes has not only reduced human error but also enhanced productivity by accelerating production speeds. Moreover, these systems provide a high level of repeatability, ensuring consistent quality across multiple iterations. Another benefit was that we were able to reduce the material waste generated by human cutting by roughly 10-15%, which allowed us to remain price-competitive on a global scale.

PT&P REF. ORIGINAL POST 05262020