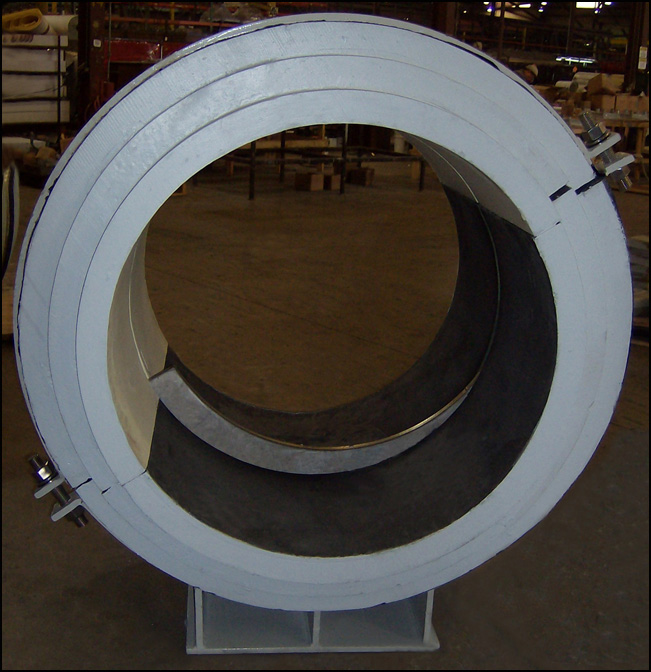

PT&P custom designed pre-insulated pipe supports with polyurethane insulation for cryogenic temperatures in a light hydrocarbon production facility in Texas. A total of 59 cold shoes were fabricated from A36 carbon steel with a hot-dipped galvanized finish. The cold shoe assemblies range in diameter from 24″-48″ and were designed to support loads ranging from 17,000 to 31,000 lb. Standard Q.C. and dimensional tests were performed prior to shipment.

Tag: Pre-Insulated Pipe Supports

Register for the Pre-Insulated Pipe Supports Webinar (Cryogenic/High Temp.)

This webinar is over, view the recording at: Webinars

This presentation will cover Pre-Insulated Pipe Supports, including pipe insulation products for both cryogenic and heat applications. Learn about the different types of insulation materials and get the inside scoop on our cold shoe design. Explore how Polyurethane foam is produced, from mixing polyols and isocyanates to inspecting the final product. Learn about anchor shoe testing, lateral load testing, compressive strength testing, and axial load testing.

The featured presenter, David Baker has over 12 years experience with pre-insulated pipe supports, on-site surveys, inspections, Installation and Maintenance. He is also the manager of PT&P’s Field Service division and our in-house consultant for pre-insulated pipe supports.

Trunnions Designed with Insulation for an LNG Facility

PT&P designed cryogenic trunnions with 2″ thick G-10 block insulation for an LNG facility in Australia. The trunnions are fabricated from 10″, 12″ and 24″ diameter pipe. The upper sections are fabricated from stainless steel pipe and plate while the lower sections are carbon steel. These insulated supports are designed for temperatures down to -300°F and operating loads of 4,990 lb.

30" Dia. Cryogenic Pipe Supports with PUF and Permali®Insulation for an LNG Facility

PT&P manufactured cryogenic pipe supports for a 30″ diameter pipeline in an LNG facility located in the UAE. These cold shoe anchors prevent axial and lateral movement at temperatures down to -300°F. The bearing plate is fabricated from carbon steel and the 5″ thick insulation is a combination of high density polyurethane foam (PUF) and Permali®.

Pre-Insulated Pipe Supports Designed for High Temperatures in a Power Plant

Piping Technology designed hot shoes with sliding bases for a power plant in Mississippi. The assemblies will be installed on 28″ diameter pipe and include 1-1/2″ thick calcium silicate insulation. Manufacturing fabricated these supports from galvanized carbon steel with a polyethylene base. They are capable of an operating load of 7,200 lb., temperatures up to 1,200 degrees F and an axial movement of +/- 4-1/2″. The shipment was met three days prior to the critical field need date.

Insulated Pipe Supports Designed for 6" Dia. Cold Temperature Piping

These insulated pipe supports are designed for 6″ diameter cold temperature piping for a gas refinery in Texas. They are fabricated with a carbon steel shell and 5″ thick polyurethane insulation. PT&P offers various types of insulated supports utilizing insulating materials designed for piping ranging in surface temperatures from -460°F to 1,200°F.

215 Heavy Duty Pre-Insulated Pipe Supports Designed for a High Temperature Application

Pipe Shields Inc., a division of PT&P, manufactured 215 heavy duty pre-insulated supports for a high temperature application in Oregon. They are 15″ L x 20″ W x 31″ H and are designed to accommodate 14″ – 20″ diameter pipes. The hot shoes have a calcium silicate insulation thickness of 2.5″- 3″. The base, clamps, nuts, jackets and bolts are all fabricated from hot dipped galvanized carbon steel and coated with red oxide paint. Standard Q.C. and dimensional tests were performed prior shipment.

42" Dia. Heavy Duty Insulated Pipe Support Anchors for a High Temperature Application

PT&P designed and fabricated heavy duty insulated pipe support anchors for a high temperature application. The base, clamps, nuts, jackets and bolts are all fabricated from hot-dipped galvanized carbon steel. The hot shoes have 3″ thick high density calcium silicate insulation, and are designed for 12″-42″ diameter pipes. The dimensions are 47″ L X 51″ W X 16″ H. Standard Q.C. and dimensional tests were performed prior to an expedited shipment.

Cryogenic and Axial Stop Cold Shoes for an LNG Facility

Piping Technology and Products supplied these cryogenic and axial stop cold shoes for an LNG facility in Australia. A total of 28 assemblies were fabricated with carbon steel, stainless steel and Micarta® G-10 insulation blocks. They were a wide range of lengths from 24″ to 36″, widths from 6 3/4″ to 30″ and heights from 9″ to 10 1/4″. The pipe shoes will support pipes ranging in diameter from 6″ to 48″ NPS in cryogenic temperatures as low as -162°C. A special paint system was used for the carbon steel components to resist rust. PMI testing was performed on the stainless parts prior to shipping.

Insulated Pipe Supports Designed for Cryogenic Temperatures Down to -320°F in an LNG facility

A total of 295 cryogenic pipe supports ranging from 4″ to 38″ NPS were designed for a LNG regasification facility in India. The shoe and bearing plates were fabricated from carbon steel, the jacket was fabricated from aluminized steel and includes a vapor barrier. 20 PCF high density polyurethane foam was used for the insulation.

Do you see a need for cryogenic supports in your piping system? Get pricing today!

Pre-Insulated Pipe Supports with 12" Thick Insulation Designed for a 49" High Temperature Line

PT&P fabricated pre-insulated pipe supports from galvanized carbon steel designed for a 49″ diameter pipe and temperatures in excess of 1600°F. The insulation is 12″ thick and composed of lime, silica and reinforcing fibers. This type of insulation features exceptional strength and extremely low water absorption. It is essentially dust-free, contains no asbestos and is a very good material for structural insulation inserts. This “hot shoe” will be used in a cat cracker unit at a refinery in Alabama.

Want to learn more about pre-insulated supports? View a recording of a past webinar now!

What is Piping Technology?

PipingTechnology and Products is the name of our company specializing in pipesupports, pre-insulated supports, slide plates, snubbers, sway braces, and muchmore. In business since 1975, Piping Technology has over 35 years of experiencein the engineering and design of high-quality pipe supports. Piping Technologyis a parent company to four subsidiaries including U.S. Bellows, Sweco Fab,Fronek Anchor/Darling Enterprises, and Pipe Shields.

Piping Technology: 35 Acre Facility

Cold Shoe Anchors with Micarta Insulation for a LNG Plant

The cold shoes are fabricated from a combination of carbon steel, micarta insulation, and stainless steel. They measure 18″ x 12″ x 10″ and are designed for 7″ of lateral movement with temperatures as low as -162°C. A total of 16 supports were manufactured and PMI tested. This was a rush order completed in just under 12 weeks for a LNG plant.

Want to learn more about pre-insulated supports? Instantly view a pre-insulated support webinar!

399 Pre-Insulated Pipe Supports for a LNG Facility

Piping Technology & Products, Inc manufactured the pre-insulated supports with 4″ of insulation thickness for pipe sizes ranging from 36″ to 56″ in diameter.

The cold shoes were fabricated from a combination of 10 and 20 PCF of polyurethane insulation. They also include a vapor barrier, aluminum jacket, acoustic layer, and are coated with a hot dipped galvanized finish. The supports will be used for a project in North Africa.

Want to learn more about pre-insulated supports? Watch a recording of a past webinar!

Pre-Insulated Pipe Supports for an LNG Plant

PT&P manufactured a total of 1,400 supports for an LNG project. 75 of those supports were cold supports completed in less than one week on an emergency basis. The cold shoes were fabricated from a combination of polyurethane foam, carbon steel metal straps, and an aluminum metal jacket for insulation. They are designed for temperatures as low as -300°F and pipe sizes ranging from 12″ to 36″ in diameter. The 36″ diameter shoes are designed for a vertical load of 102,000 lb. and the 12″ diameter shoes are designed for 36,000 lb. load.

Do you require pre-insulated supports in your piping system? Get a quote from us now!

84" Pre-Insulated Pipe Support for High Temperatures

Designed for a pipe size of 84″, this pre-insulated pipe support is able to withstand temperatures up to 1,220ºF. It is a wide base sliding hot shoe with up to 2″ of axial travel and 3″ of lateral travel. It can support loads up to 33,721 lb. and the support itself weighs approximately 1,900 lb. This high temperature pre-insulated pipe support will be utilized in a styrene plant.

Want to learn more about pre-insulated supports? Watch a pre-insulated support webinar now!

Cold Insulated Pipe Anchors for an LNG Plant

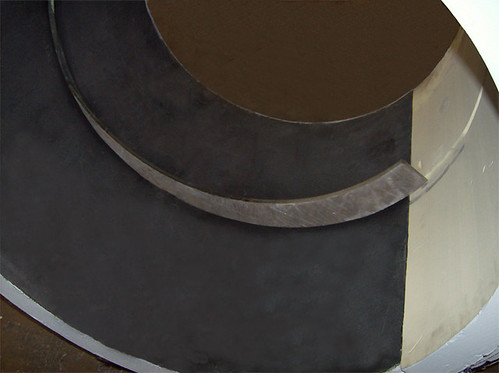

Piping Technology & Products designed and fabricated 36″ diameter insulated pipe anchors that included base stops to prevent lateral and axial movement of the anchor.

The design of the insulated stop plates allows the anchor to withstand 63,000 lbs of axial load. The use of Polyurethane insulation allows for operating temperatures down to -300°F.

Do you require insulated pipe anchors for your piping system? Get pricing today!

Hot Shoes for a Power Plant in Argentina

Piping Technology and Products, Inc. received an order for a power plant in Argentina from our Pipe Shields division. This order consisted of variable assemblies, constant support assemblies, sway struts, and pre insulated pipe supports. Pipe sizes supported were up to 42” with 3” of insulation ranging from 340 lb. to 1300 lb. All hot shoes were designed to carry the load, along with its own weight and insulation. Since these pre-insulated supports are used for high temperature pipes, PT&P used calcium silicate as insulation and hot dipped galvanized the steel as a rust inhibitor. Piping Technology and Products Inc. handled all logistics of the international shipment.

Do you require hot shoes for your plant or refinery? Let us price them for you today!

75 Hot Shoes for a Construction Project in New Hampshire

These pre-insulated hot shoes are manufactured from carbon steel and insulated with Firetemp® and Foamglas. Firetemp® is a structural insert designed to carry the load capacity of the pipe while Foamglas is fragile and can support temperatures of up to 900F. The hot shoes measure 19 long with the base of pipe at 6. They weigh between 58 lbs to 185 lbs. The pre-insulated shoes are designed to maintain the insulated pipes at a temperature for functionality.

Do you require hot shoes like the ones described above? Let us price them for you now!

68 Sliding Cold Shoes with Lateral Restraint

Piping Technology and Products, Inc. recently fabricated and designed several sliding cold shoes with lateral restraint for a river site in Georgia. The sliding cold shoes have a frame of A36 carbon steel. These were designed to support pipes of 14 to 36 in diameter, insulated with 4.5 to 5 in thick layers of polyurethane foam.

Want to learn more about cold shoes? View a past pre-insulated support webinar!