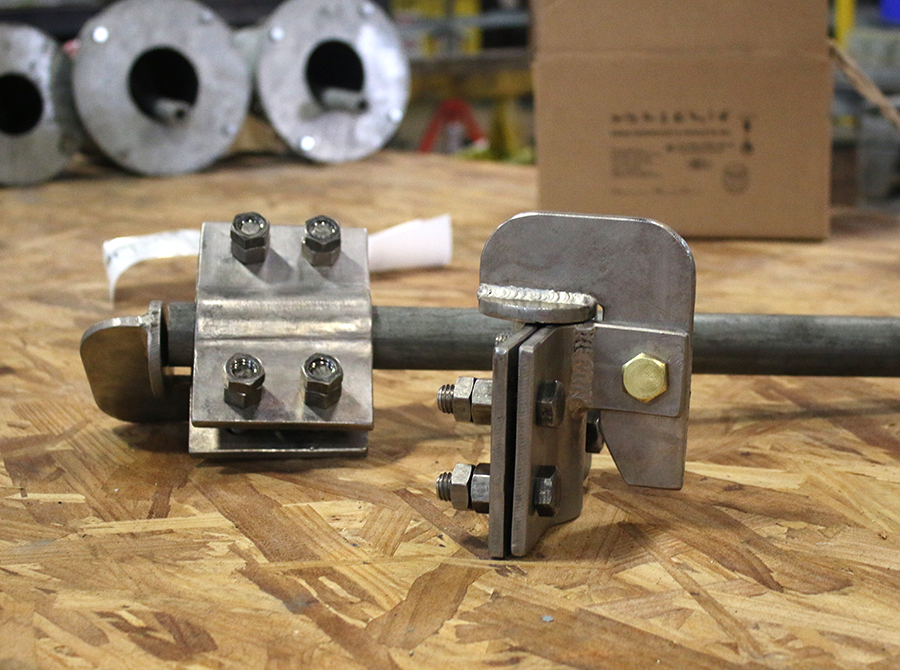

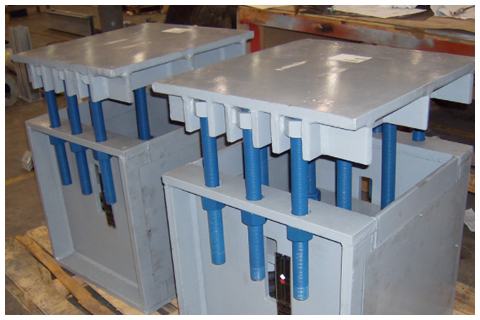

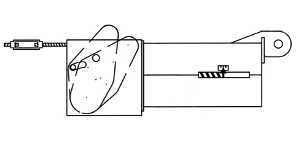

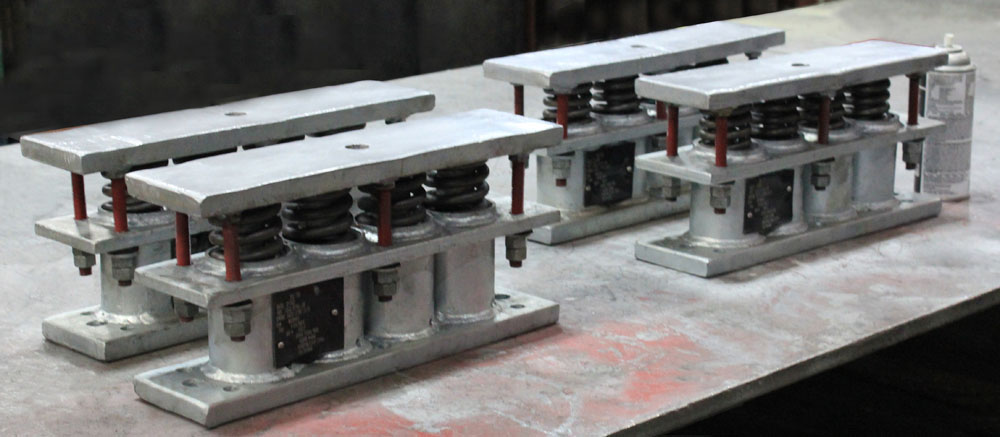

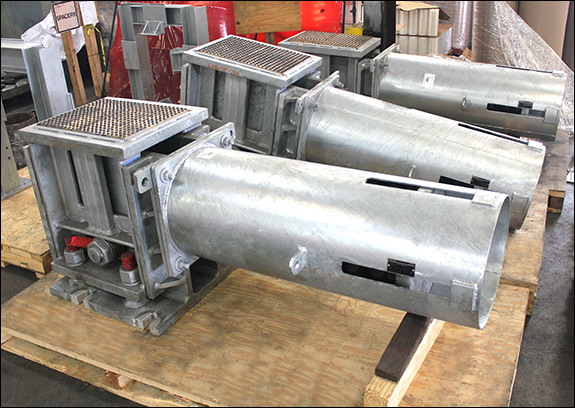

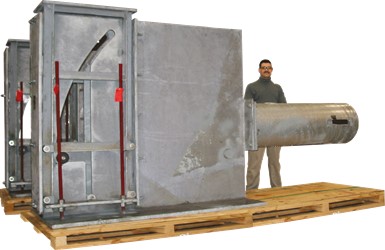

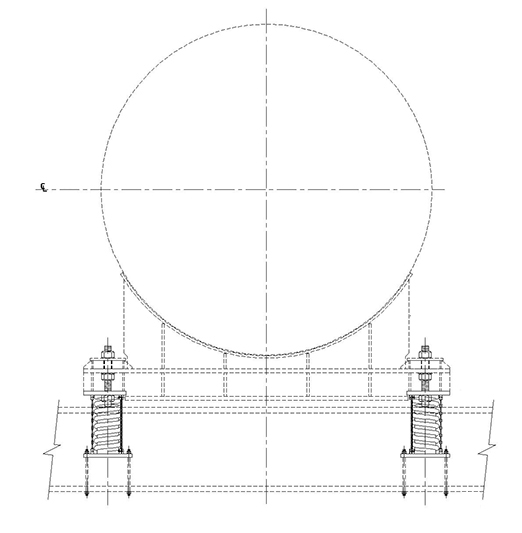

PT&P custom-designed and fabricated "saddle support spring isolators" to replace the previous springs originally designed in 1974 for supporting an old steam chest saddle at a chlor-alkali chemical plant. Chlor-alkali plants use salt and electricity to produce caustic soda and chlorine gas. Downstream, the chlorine gas – either wet or optionally dry – can be reacted in a chemical process to produce bleach, other chlorine derivatives, or chemical feed stocks finding its way into the production of glass, plastics, pulp, paper, textiles, vinyl, antiseptics, insecticides, and a water treatment agent and in some soaps and detergents. Rising demand for chlorine and caustic soda in various industries such as automotive, pharmaceuticals, paper, and chemicals are driving the chlor-alkali market. Due to improvements in the manufacture of spring coils, PT&P’s engineering team suggested improvements to the original design using a more well-suited design that exceeds the original design specifications. These saddle supports include PTFE, 25% glass-filled slide plates bonded to the top of the assembly. They are designed to support up to 32,000 lb. each with a 6,250 lb/in. spring rate. These springs do not have the traditional spring housing typically used to encase the spring coil, instead, they are fabricated utilizing carbon steel plates in conjunction with chains and internal components. See diagram below.

The spring coils are alloy steel and were custom designed per this customer’s specified wire dia, active/total coils, and solid height. The spring supports were load tested and a quality control inspection was completed that included MAG Particle Inspection. PT&P can replace existing custom variable spring supports using the original design drawings from plants built more than 50 years ago. PT&P can also reverse engineer any spring hanger by taking detailed measurements of the support in the field and sending the information back to our shop for a quick lead time during a plant turnaround or shutdown. Many of the custom spring supports that PT&P has supplied to replace original equipment have been in service for more than 40 years.

PT&P REF. ORIGINAL POST 11022021