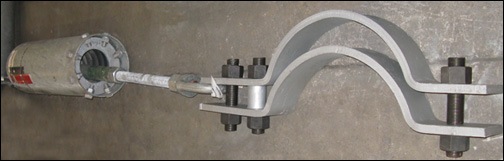

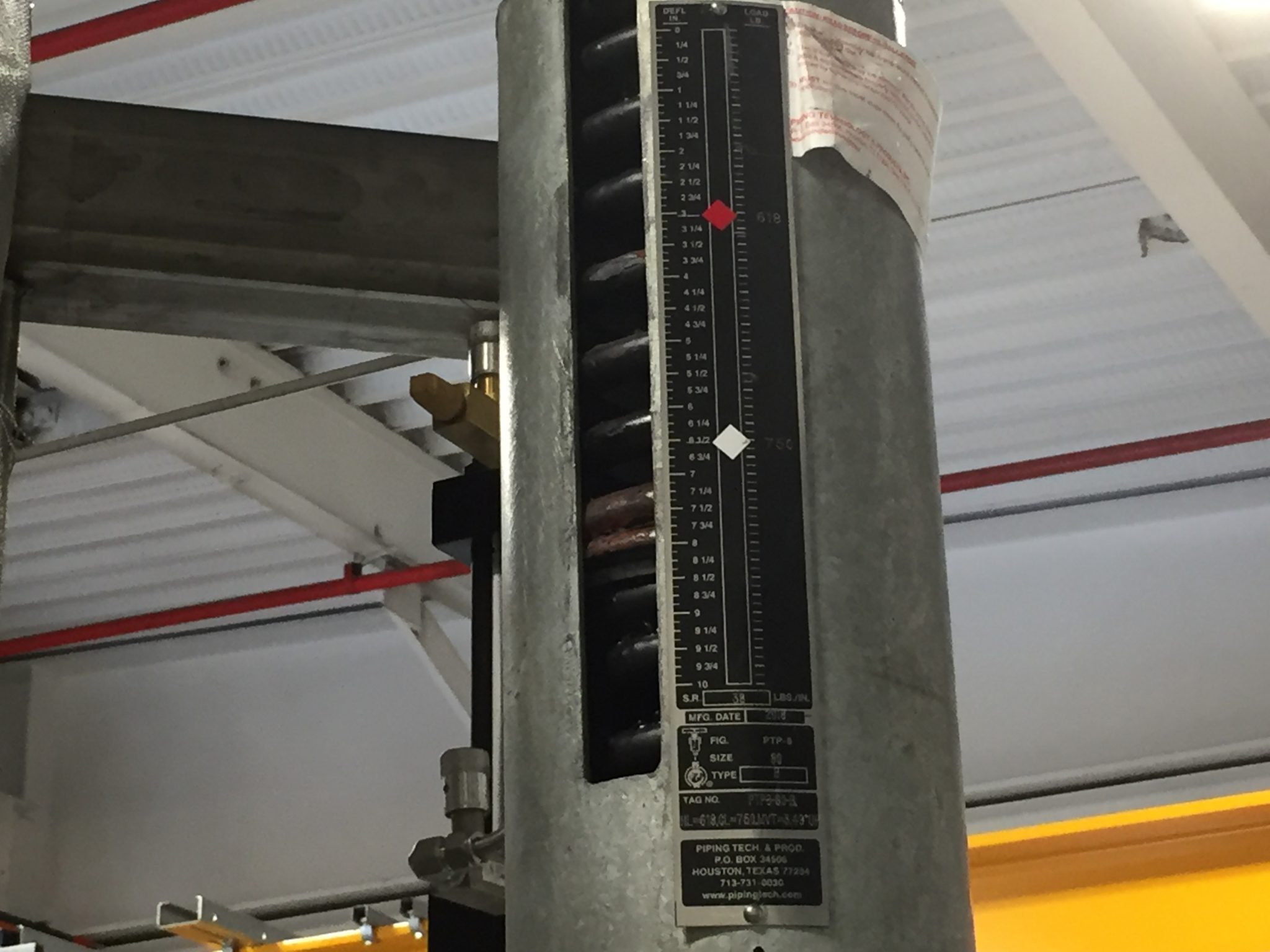

| Type: | G-Type Variable Spring Support Assemblies |

| Design: | Operating Loads from 3000 lb. to 4000 lb. Movement of 1” |

| Material: | Carbon Steel |

| Testing: | Load & Travel Test | Q.C. Inspection |

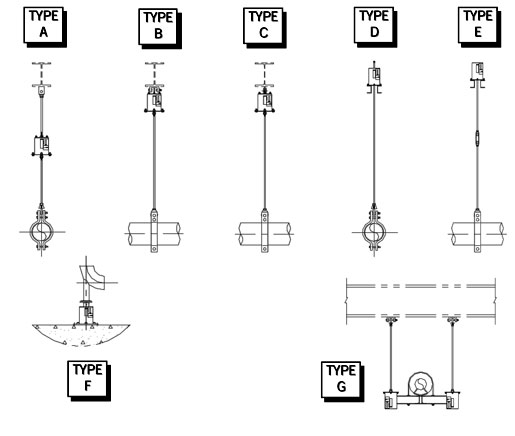

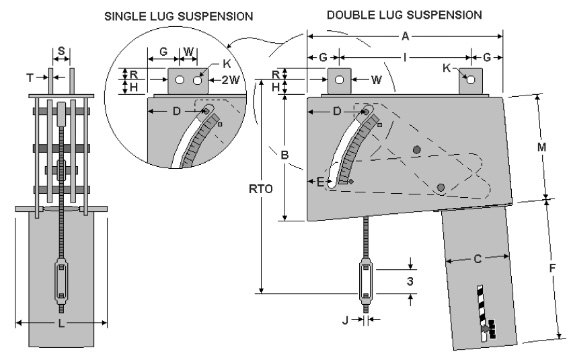

Pictured here is a Type G variable spring hanger assembly designed for an operating load up to 4000 lb. and 1” movement. This type of support assembly is formed by welding two standard spring assemblies to the ends of a pair of channels. The Type G assembly is especially adaptable for avoiding interference in spaces where the headroom is limited. The assemblies are fabricated from carbon steel and underwent spring load tests before shipment.