PT&P designed and fabricated 112 variable spring supports for a furnace application at an oil refinery in California. The spring cans are fabricated from carbon steel, vary from 36″ to 54″ in height and designed to operate at 400°F. The furnace cans are designed for operating loads ranging from 180 lb. to 1,400 lb. and movements from 1″ to 5″. The customer specified a custom paint system of two part iron oxide blue finish for the cans to comply with refinery conditions. Load tests were performed on the assemblies prior to shipment to determine the operating load and variability.

Tag: Variable Springs

C-Type Variable Spring Support Assemblies Designed for an Oil Sands Mine

PTP-2 160 C-Type variable spring support assemblies were designed and fabricated for an oil sands mine in Canada. The variables are 8″-12″ diameter, 16″ to 32-1/2″ overall length, and designed for an operating load of 5590 lb. with an upwards travel of 0.787″. The variables were fabricated from carbon steel with a hot-dipped galvanized finish and standard load and travel testing was completed prior to shipment.

Custom Sway Brace and Variable Spring Assemblies Designed for an Aerospace Development Facility

These custom designed sway braces and variable spring assemblies were designed for hanger duct work in an aerospace development facility. The assemblies measure 67-1/2″ long with a 14-1/8″ O.D. The variables are a modified F-type spring with a pivoting base and non-standard coil combination, including a nested spring design. The assemblies include fully adjustable travel stops and custom end brackets. They are fabricated from carbon steel and designed for load ranges between 1100 lb. and 9250 lb. with a spring rate of +/- 2.78″.

Variable Spring Hanger and Pipe Clamp Assemblies Designed for a Cogeneration Plant in Canada

These variable spring hanger and pipe clamp assemblies were custom designed for pipes ranging from 6″ to 20″ diameters at a co-generation plant in Canada. The spring can, threaded rods, weldless eyenuts, welded beam attachments and Fig. 80 pipe clamps were fabricated from hot-dipped galvanized carbon steel. The assemblies are capable of an overall load of 10,790 lb. with a total travel of 1/2″. A total of 21 spring hanger and clamp assemblies underwent standard load and travel testing.

Solution for Removing Travel Stops in Variable Cans with Heavy Loads

For spring cans capable of 40,000 lb. or greater, we recommend you use jacking bolts to remove the travel stops. Visit our visual media section to learn the Solution for Removing Travel Stops at Heavy Loads.

New Spring Sizing Calculator

Don’t know your cold / installed load? Use our new web-based spring sizing calculator to find all the springs that can fit your design parameters.

Is neoprene or galvanized coating a better option?

Neoprene coating is generally applied to pipe support components thatrequire flexibility such as spring coils whereas the hot dipped galvanizingcoating would be applied to rigid pipe support components.

Spring Coil with Neoprene Coating

F-Type Variable Spring Supports for a Chemical Plant and Refinery in Singapore

An assortment of standard variable spring supports were manufactured ranging in size from 8-5/8″ to 12-3/4″ dia. with installed heights ranging from 9-7/16″ to 18-1/8″. The F-Type pipe hanger assembly is used to support the pipe from below and are typically mounted to concrete pads via anchor bolts or welded to structural steel. The various springs shown are designed for operating conditions ranging from loads of 1750 lb. with .02″ travel to 21,280 lb. loads with .13″ travel. As with all of our variable supports, these were quality checked with a 100% spring coil deflection test and a load cell calibration to set the assembly at the prescribed installed load.

Do you see a need for variable springs in your piping system? Let us price them for you!

Constant Spring Supports vs. Variable Spring Supports

Ever wonder what makes a constant spring support different from a variable spring support? How does each one function? How do they support loads and allow for movement in a pipeline? Check out our new spring support article that provides all the answers to these questions and more.

Want to learn more about constants? Instantly view a past constants webinar now!

F-Type Variable Springs with Slide Plates

PT&P fabricated variable springs from hot-dipped galvanized carbon steel components and a neoprene coated spring steel coil. P.T.F.E. slide plates are welded to the load flange to reduce frictional forces generated during lateral movement of the supported pipe. Internal guides are also installed to help maintain vertical alignment of all moving components throughout the anticipated thermal deflection cycle. The installed (cold) load is set to 10,413 lb. With a design travel of 0.720” up, the final operating (hot) load will be 8,974 lb. Each spring is equipped with travel stops and went through load testing prior to shipping.

Want to learn more about variable springs? Instantly view a past variables webinar!

F-Type Variable Springs with Fully Adjustable Travel Stops

Piping Technology & Products, Inc. manufactured a variety of F-type variable springs with loads ranging from 526 lb. to 33723 lb. These variable springs are fabricated from a combination of carbon steel and A193-B7 CroMoly steel with A304 stainless steel slide plates. The variable springs are modified to include fully adjustable travel stops. The first purpose of the adjustable travel stops is to aid by distributing the load evenly during the installation process. The second purpose is to allow spring adjustment to any load within the operating range.

Do you see a need for variable springs in your project? Get pricing today!

F-Type Variable Springs for a Local Chemical Plant

Pictured above are F-type variable spring supports designed for a local chemical plant. They are designed for a vertical movement of 1/8″ and an operating load ranging from 638 lb. to 2,612 lb. Fabricated using A-36 carbon steel components from our shop inventory, these variables include PTFE, 25% glass filled, slide plates to allow for translational movement. Each spring is preset to the specified installed load prior to shipment.

Do you see a need for variable springs in your plant? Get pricing today!

7'- 6" Long Custom Variable Spring Hangers

These variable spring hangers were custom designed per customer specifications for a power plant in Turkey. The pipe hanger assembly measures 7′- 6″ long and the diameter of the can measures 12″. The variable spring hanger is capable of 55,137 lb. of hot load and 63,339 lb. of cold load. The assembly allows for 1″ upward travel.

In order to achieve the required spring rate, PT&P utilized a set of stacked coils (5 5/8″ O.D.) nested inside a larger coil. This produced an overall spring rate of 9,235 lb/in. The upper and lower attachments were minimized to fit within the space requirements provided.

Do you see a need for variable springs in your application? Get pricing today!

Variable Springs for a Project in Mexico

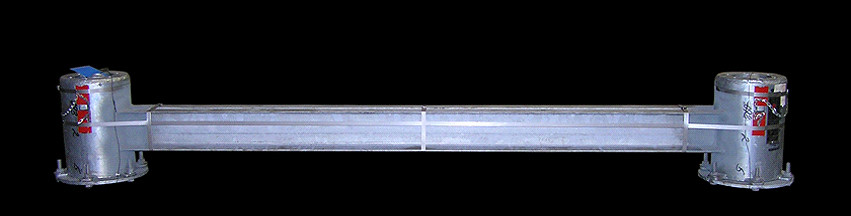

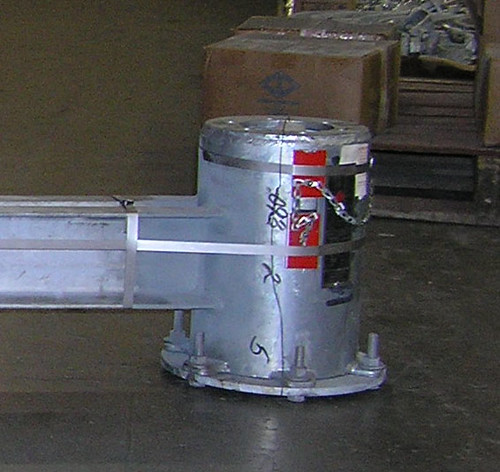

This Type G variable spring was manufactured for a Petrochemical Plant in Mexico. The Type G assembly is formed by welding two standard spring assemblies to the ends of a pair of channels. This type of assembly can accommodate unusually heavy loads, and is especially convenient for avoiding interference in spaces where headroom is limited.

Each spring assembly is loaded per the client’s specification at Piping Technology and Products manufacturing facilities. A travel stop is inserted and strapped in place to maintain the load for the assembly installation. In addition to banding the travel stops, the variables for this project required chained travel stops. The base style (F-Type) variables on this project were also required to have internal guides.

At Piping Technology and Products, Inc. we use PTP-1, PTP-2, PTP-4, PTP-6 and PTP-8 to designate the five standard coil arrangements to increase the working range of travel of variable supports.

Several types of variable supports were made for this particular project. They included Type A, Type B and Type F.

Do you require variable spring supports in your piping system? Get pricing today!

March 2006 News

Piping Technology & Products, Inc. Performed Field Services for a Power Generating Plant in Texas

PT&P was contracted to assist in the determination of pipe support maintenance at a power plant in Texas. The constant effort support springs with loads of excess of 9,500 lbs and the variable spring supports with loads of 450 lbs were marked for needing attention.

PT&P’s objectives were to:

* Evaluate the pipe supports

* Determine state of performance

* Provide a plan of action

* Train personnel on-site to perform adjustments and replacement of supports or support components

* Provide final inspection of modified supports

The pipe supports needing attention could not be set to the required installation position. A plan was initiated to recondition some of the support components such as turnbuckles and rods. This would allow a greater range of field adjustment to the pipe supports. During a planned shut-down, PT&P Field Service Units returned to the site to modify the existing supports. The initial phase of the modifications included bracing the piping in order to isolate and lock the supports in position. Then, they were disconnected from the system and modifications to the assemblies were completed. Afterwards, the supports were reinstalled and any necessary adjustments were completed. A total of eight pipe supports were modified or adjusted.

Do you see a need for a routine inspection of your plant? Contact us for a quote today!

PTP 1-140 Type F Positive Variable Springs for a Power Plant

All of the custom designed variables consist of a single flange with two spring supports in order to meet the customer’s height restrictions. These PTP1-140 Type F variable springs are fabricated from A36 carbon steel with an overall weight of 16,900 lbs. They are designed for upward movement of 0.079″ with a hot load of 4,490 lbs., and a cold load of 4,620 lbs.

Want to learn more about variable springs? View a past variable spring webinar now!

Eight Custom-Built Variable Springs for a Power Plant

All of the spring components are made of A4150H and carbon steel. Per customer’s request, a two coat epoxy paint was applied to the springs. The Type-A variable spring assemblies measure 22″ x 79″ with an installed load of 45,000 lb., operating load of 56,000 lb., and a downward travel of 5″. The Type-C assemblies measure 22″ x 89″ with an installation load of 38,000 lb., operating load of 47,000 lb., and a downward travel of 5 1/2″. Each spring coil was tested to insure the wire diameter, coil height, and spring rates.

Do you see a need for variable springs in your piping system? Get a price quote today!

Spring Supports with PTFE, 25% Glass Filled, Slide Plates

Piping Technology & Products, Inc. recently custom designed and manufactured 32 spring supports with PTFE, 25% glass filled, slide plates for a plant in China. The total weight of the spring supports supplied is 13,143 lbs. and they have a travel range of ¾”. These products support the vessel and the PTFE, 25% glass filled, slide plates allow height adjustment as well as mobility. These spring supports are designed for operating loads of 42,266 lbs. and were constructed of carbon steel.

Do you require spring supports or slide plates in your piping system? Get pricing now!

Custom Variable Springs for Power Plant

Piping Technology and Products, Inc. custom designed and manufactured variable springs to be used in conjunction with a rod and clevis assembly for a power plant in West Virginia. Since the operating loads specified by the customer were greater than the maximum loads for the largest PT&P spring, custom units needed to be built for this application. The springs were fabricated using a large spring coil, normally only used in constant spring assemblies. The spring is 20 1/2″ in diameter and has a standing height of 51″. All components of the pipe hanger assembly were made from carbon steel and were supplied with a hot-dipped galvanized finish. The spring is 20 1/2″ in diameter and has a standing height of 51″. The rods will be attached to type A variable springs designed to support loads from 850 lbs. to 13,300 lbs. Manufactured from A-36 carbon steel, the rods are 3/4″ to 2″ in diameter and range in length from 68″ to 95″.

To prevent contamination at high temperatures, a non-galvanized finish was applied to the rods per customer’s request. Prior to delivery, a 100% dye-penetrant test was preformed to ensure quality. The variable springs were tested in the load cell to insure proper operation and also to set the cold load to the specifications as provided by the customer.

Want to learn more about variable springs? Instantly view a past variable webinar!

6600 lb. load PTP-4 Type C Variable Springs with Riser Clamps

PT&P recently designed and manufactured six, PTP-4-160 type C variable springs with riser clamps for an oil refinery in Texas. These variable springs are constructed from carbon steel and designed to support loads of 6600 lb. with a total travel of 2″. The clamps are fabricated from A 387 Gr. 22 alloy steel to fit 18″ pipes. Dimensional and fit-up tests were performed on the variable springs and riser clamps prior to shipping.

Do you see a need for variable springs in your current or upcoming project? Get pricing!