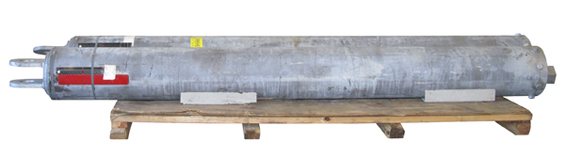

PT&P designed G-Type variable spring supports for a chemical plant in Texas. The variables are comprised of two standard spring housing joined together with an intermediate bridge assembly. The bridge assembly is customized to match existing site conditions which allows for use in applications with limited space or interferences. The variables are fabricated from carbon steel with a hot-dipped galvanized finish. The assemblies were designed for a total operating load of 23,522 lb. with a downward design travel of 3/8″. Each assembly underwent a standard load test prior to shipment.

Tag: Variables

Variable Spring Supports Custom Designed for a Furnace Application in an Ammonia Plant

PT&P custom designed variable spring supports for catalyst tubes in a furnace for an ammonia plant in Canada. The furnace springs are fabricated from carbon steel and painted with a red-oxide primer to help prevent corrosion. This project required special coils that were within +/- 5% of the calculated spring rate. Over 245 springs underwent calibration test prior to shipment. PT&P has been supplying furnace springs for over 25 years and can customize them to meet your specifications.

Variable Spring Hangers Designed for an Oil Sands Expansion Project

Piping Technology & Products designed and fabricated 107 variable spring hanger assemblies for an Oil Sands Expansion Project in a central processing facility in Canada. We fabricated these C-type variable springs from hot-dipped galvanized carbon steel. The design loads range from 3,343 lb. to 3,417 lb., and each assembly underwent a series of tests and detailed quality control inspections prior to shipment.

F-type Variable Spring Supports Designed for a Petroleum Facility

PT&P designs thirty F-type variables spring supports for a petroleum facility in Canada. The springs are fabricated from carbon steel and with a hot-dipped galvanized finish. The assemblies are internally guided and have a 3,455 lb. operating load. A standard travel test was conducted on the variables prior to shipment.

G-Type Variable Spring Supports Designed for a Paper Manufacturing Plant

PT&P designed G-Type variable spring supports for a paper manufacturing plant in Minnesota. The variables are comprised of two standard spring housing coil subassemblies joined together with an intermediate bridge assembly. The bridge assembly is customized to match existing site conditions which allows for use in applications with limited space or interferences. The variables are fabricated from carbon steel with a hot-dipped galvanized finish. The assemblies were designed for a total operating load of 1,348 lb. with an upward design travel of 0.8013″. Each assembly underwent a standard load test prior to shipment.

112 Custom Variable Springs Designed for a Furnace Application in Venezuela

112 custom variable springs designed for a furnace application for an oil refinery in Venezuela. The furnace cans are designed from carbon steel and painted with red oxide primer to prevent corrosion when exposed to high temperatures. The sizes of these figures PTP-6 and PTP-8 range in length from 25″- 39″, with a total travel of 0.1″- 1.821″ and loads varying from 430 – 681 lb. A load test to confirm the spring rate was conducted on each assembly prior to shipment.

Variable Spring & Graphite Slide Plate Assemblies Custom Designed for Gasoline Production in Dubai

In eight weeks, PT&P provided a gasoline production plant in Dubai with two custom designed variable assemblies. Each assembly includes load columns, four variable spring cans, four channels, 12 plates, nine graphite slide plates and a custom designed frame. The frame allows the variable springs to work in unison to support large pipe trunnions. The top plates measure 45″ in width and 25″ in height. The variables are designed for an operating temperature of 750°F and an operating load of 3,150 lb. The assemblies are capable of 1/8″ upward movement and 1/6″ downward movement. A load test was conducted prior to shipment.

F-Type and C-Type Variable Spring Supports for an Acid Plant in Canada

PT&P designed and fabricated F-type and C-type variable spring supports for an acid plant in Canada. The variables range from 4″-8″ in diameter and can accommodate between .039″– 5.02″ in movement. They are designed for an operating temperature of 200°F and operating loads between 509 lb. and 13,489 lb. The variable springs are coated with a red oxide coating to protect against corrosion and underwent standard and load travel tests prior to shipment.

Variable Spring Hanger and Pipe Clamp Assemblies Designed for a Cogeneration Plant in Canada

These variable spring hanger and pipe clamp assemblies were custom designed for pipes ranging from 6″ to 20″ diameters at a co-generation plant in Canada. The spring can, threaded rods, weldless eyenuts, welded beam attachments and Fig. 80 pipe clamps were fabricated from hot-dipped galvanized carbon steel. The assemblies are capable of an overall load of 10,790 lb. with a total travel of 1/2″. A total of 21 spring hanger and clamp assemblies underwent standard load and travel testing.

New Webinar: Pipe Supports for Beginners- Constants & Variables

View the recording at: Webinars

This webinar series was created to explain the basic principles of different types of pipe supports in the simplest way possible. It is geared towards “non-engineers” who want to have a better understanding of pipe supports. This particular presentation will give you a brief introduction to pipe supports and will then solely concentrate on constant and variable spring supports. It will explain the various designs, applications, and details of each support using simple terms and a lot of visual aids. The presentation will conclude with general guidelines of the maintenance and ordering process of constants and variables.

New Spring Sizing Calculator

Don’t know your cold / installed load? Use our new web-based spring sizing calculator to find all the springs that can fit your design parameters.

F-Type Variable Spring Supports for a Chemical Plant and Refinery in Singapore

An assortment of standard variable spring supports were manufactured ranging in size from 8-5/8″ to 12-3/4″ dia. with installed heights ranging from 9-7/16″ to 18-1/8″. The F-Type pipe hanger assembly is used to support the pipe from below and are typically mounted to concrete pads via anchor bolts or welded to structural steel. The various springs shown are designed for operating conditions ranging from loads of 1750 lb. with .02″ travel to 21,280 lb. loads with .13″ travel. As with all of our variable supports, these were quality checked with a 100% spring coil deflection test and a load cell calibration to set the assembly at the prescribed installed load.

Do you see a need for variable springs in your piping system? Let us price them for you!

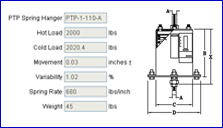

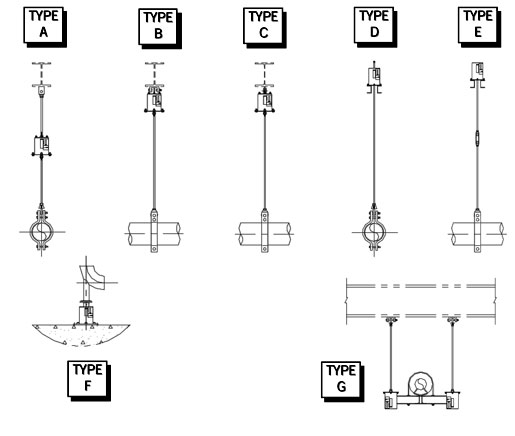

How do you attach a spring support to a rod?

There are different ways to attach a spring support to a rod.

For A-Type constants and variables, you need two separate rods. The top plate of the assembly includes a threaded piece that will connect to an upper rod. A second rod will be connected to the bottom by the spring’s threaded load column.

For B-Type and C-Type constants and variables, you need one rod to attach to the spring assembly’s threaded load column.

For D-Type and E-Type variables, a single rod runs from the bottom through the top of the spring and hex nuts are used to secure the rod in place.

For D-Type and E-Type constants, a single rod is attached using a turnbuckle.

How do I remove a spring support?

In order to remove a spring support, first you must ensure that the spring is at its designed cold (installed) position. Next, re-install the travel stop(s) in the support. Then, provide adequate temporary support for the piping system. Once you have adequate support, you can release the load from the spring. Finally, remove the spring support from the piping system.

Variable Spring Support with Travel Stops in Place

Variable Spring and Cro-Moly 3-bolt Clamp Assemblies for a Power Generation Facility

The variable spring and clamp assemblies are fabricated using a combination of carbon steel for the housing and internal components, spring steel for the spring coils, and Cro-Moly (A-387 GR. 22) for the high temperature 3-bolt clamps. This pipe hanger assembly is an example of PT&P’s standard variable spring design wherein multiple coils are arranged in series to produce adequate load carrying capacity and coil deflection to compensate for the anticipated pipe movement. These particular assemblies are capable of an overall load range of 9,320 lb. to 15,970 lb. with a total travel range of 5″. All pipe hanger assemblies underwent standard load and travel testing, 100% deflection testing, and load cell calibration before shipping to a power generation facility.

Want to learn more about variable springs? Watch a recorded variables webinar!

120 3/8″ Long Custom Variable Spring Supports with Four Individual Coils

These variable springs are custom designed from carbon steel material. The springs are fabricated with extra long housings to allow for a pre-compression lower than the standard. This ensured that the starting (cold) load of 26,745 lb. could be achieved. The springs are designed for a movement of 5.55″ downward, which would produce an operating load for each assembly of 38,305 lb. These springs are to be utilized in pairs together with a 22″ riser clamp to produce a 407″ total pipe hanger assembly length and an overall combined operating load of 76,610 lb.

Want to learn more about variable springs? Watch a past variable springs webinar today!

23″ Modified F-Type Variable Springs with Rollers

PT&P custom designed and fabricated these F-type variable springs with rollers to be used in a refinery in Kansas. The variables are fabricated from carbon steel with a stainless steel clamp-on shoe that attaches to the load column. These F-type variable spring assemblies measure 23″ in height and have an upward travel of 3″. The operating load is 1,000 lb. and the installed load is 1,300 lb. The function of this custom designed variable spring is to allow large axial movement along the axis of the pipe centerline. The load column is modified to accommodate the special clamp-on shoe. The customized wheels allow for movement of the entire spring assembly in conjuction with the pipe.

Do you require variable springs for a similar application? Get a price quote today!

5,800 lb. load Type F Variable Springs

Piping Technology and Products, Inc. recently designed and fabricated eighteen 1,200 lb to 5,800 lb. load PTP-2 type F size 100 to 150 variable springs for a company in South Korea. These variable springs fabricated from carbon steel are designed for 200°F. They have an overall height of 9.5″ to 11.5″ and are designed for a travel range of 1/8″ upward to 3/16″ downward. Per the customer’s request the variables were coated with a custom paint. To ensure quality, standard load testing was performed on the variables prior to shipping.

Want to learn more about variable springs? Instantly watch a variable spring webinar now!

PT&P Aids in the Construction of an Oil Refinery

Piping Technology & Products, Inc. has designed and manufactured over 177 tons of supports for the Chad/Cameroon Development Project in Chad, Africa. Adjustable Base Supports designed to support pipe size ranging from 3 to 18″ in diameter were one type of the many supports fabricated for this project.

Each of the hot-dipped galvanized pipe stands has an 8″x8″ base plate and a midrange height of 12″. The pipe stands allow for a maximum travel of +/- 3″. These supports provide for easy adjustment in the field when supporting pipe trunnions on concrete pads or foundations. In addition, these pipe stands have a major advantage when the exact installation heights are not known at the remote job site.

Other supports including constants and variables spring hangers, rigid rod hangers, structural steel, FRP pads, and pre-insulated pipe supports were also manufactured in a range of different specifications and materials.

Want to learn more about variable springs? View a past variable spring webinar now!

PT&P Aids in the Construction of a New Petro-Chemical Facility

The photograph above shows construction site of a new petro-chemical facility near Houston, Texas. Pipe supports supplied by Piping Technology & Products, Inc., including variable spring supports, are shown in the foreground. Piping Technology & Products, Inc. fabricates expansion joints, hot and cold shoes and other items to specification for the piping industry.

Piping Technologies & Products, Inc. has a highly qualified engineering staff to meet the most critical requirements of the industry.

Need pipe supports for your new facility? Allow us to price them for you!