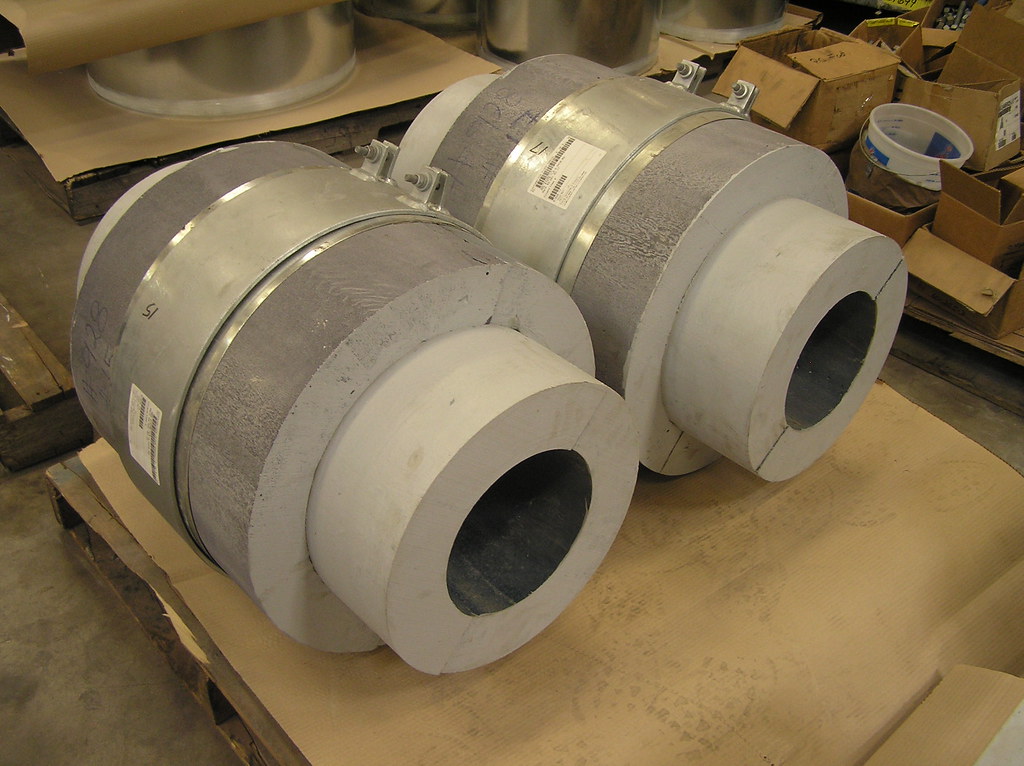

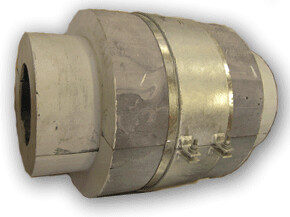

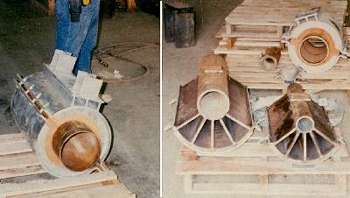

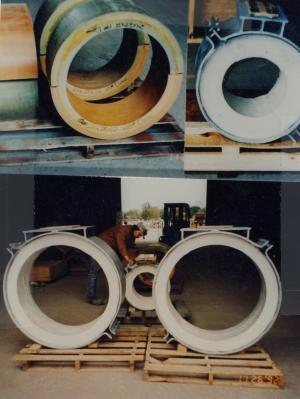

Fifty Pre-Insulated Cryogenic Supports with PTFE, 25% Glass Filled, Slide Plates were manufactured for a 36” stainless steel piping system. The steel portion of the Cryogenic Supports is fabricated from ASTMA 240 Grade 304L stainless steel. The insulation used for the Slide Plate is Micarta, capable of supporting temperatures as low as -300°F. Each Pre-Insulated Cryogenic Support is 72” in length and weighs 2,000 lbs. It is designed to support the pipeline and accommodate 45” of axial travel at each support. They are used as Cryogenic Pipe Supports for a piping system that crosses a 1,000 foot suspension bridge.

Want to learn more about pre-insulated pipe supports? View a past webinar today!