We provided a quantity of 274 custom designed hot shoes on an expedited basis to a factory in Arizona. While the normal delivery time on a typical order might be 6-8 weeks, Piping Technology provided these pipe shoes on a 3 week delivery time. The high temperature pipe supports include clamping material fabricated from carbon steel with a red oxide finish, a polyethylene slide base with stainless steel slide plates, high density calcium silicate insulation and an overlapping galvanized sheet metal jacket. The pipe shoes are designed to accommodate 4″-8″ pipes and have an insulation thickness of 2″-3″ and the base measures 11″ to 14″ in width, and 6″ to 15″ in length. The hot shoes are designed for temperatures ranging from 40° F to 600° F. The insulation for these supports is a combination of high density calcium silicate with high strength inserts.

Tag: Hot Shoes

Custom High Temperature Pipe Supports for a Granular Activated Carbon Manufacturing Plant

These high temperature pipe supports have a 25″ outside diameter, and were custom designed for a granular activated carbon manufacturing plant in Hawaii. They are fabricated from A-36 carbon steel with 10″ thick high density calcium silicate insulation. The hot shoes were designed for a 4″ diameter pipe-line, temperatures up to 1,800°F and an operating load of 1,000 lb. Standard Q.C. and dimensional tests were performed prior to an expedited shipment.

Do you require hot shoes on an upcoming project? Get pricing today!

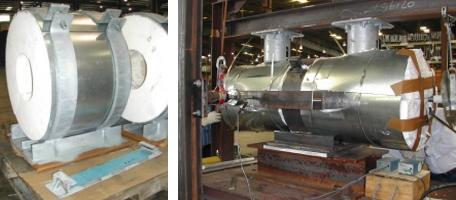

Pre-Insulated Pipe Supports with 12" Thick Insulation Designed for a 49" High Temperature Line

PT&P fabricated pre-insulated pipe supports from galvanized carbon steel designed for a 49″ diameter pipe and temperatures in excess of 1600°F. The insulation is 12″ thick and composed of lime, silica and reinforcing fibers. This type of insulation features exceptional strength and extremely low water absorption. It is essentially dust-free, contains no asbestos and is a very good material for structural insulation inserts. This “hot shoe” will be used in a cat cracker unit at a refinery in Alabama.

Want to learn more about pre-insulated supports? View a recording of a past webinar now!

164 Wide Base Sliding Insulated Supports for a Power Station

The hot shoes are fabricated from A-36 carbon steel with 304 stainless steel slide plates. The 18″ dia. hot shoe has a maximum vertical load of 5500 lb. and the 24″ dia. hot shoe is capable of loads up to 13,750 lb. All the supports in this project are designed for temperatures of up to 1200°F. In addition to the insulation, these supports are capable of sliding axially or laterally as part of the piping system.

84" Pre-Insulated Pipe Support for High Temperatures

Designed for a pipe size of 84″, this pre-insulated pipe support is able to withstand temperatures up to 1,220ºF. It is a wide base sliding hot shoe with up to 2″ of axial travel and 3″ of lateral travel. It can support loads up to 33,721 lb. and the support itself weighs approximately 1,900 lb. This high temperature pre-insulated pipe support will be utilized in a styrene plant.

Want to learn more about pre-insulated supports? Watch a pre-insulated support webinar now!

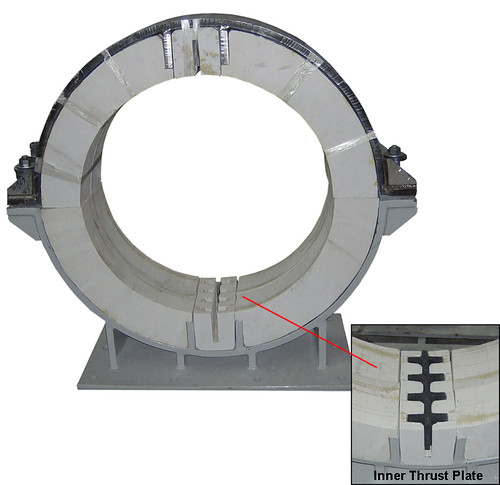

Refractory Lined Pre-Insulated Supports

Piping Technology & Products, Inc. designed and fabricated rotational anchor pre-insulated pipe supports for a fluid processing plant in Kuwait. The supports range in size from 24″ to 34″ in diameter and are capable of withstanding 12,500 lb. of vertical load. The bottom of the hot shoe is fabricated from carbon steel and the top from stainless steel.

These supports include stainless steel inner thrust plates that function as an anchor to prohibit the pipe from rotating within the shoe. These supports are designed for steam super heater lines and provide thermal insulation for the pipe in order to prevent heat loss and condensation.

Want to learn more about pre-insulated supports? Instantly watch a pre-insulated support webinar!

Hot Shoes for a Power Plant in Argentina

Piping Technology and Products, Inc. received an order for a power plant in Argentina from our Pipe Shields division. This order consisted of variable assemblies, constant support assemblies, sway struts, and pre insulated pipe supports. Pipe sizes supported were up to 42” with 3” of insulation ranging from 340 lb. to 1300 lb. All hot shoes were designed to carry the load, along with its own weight and insulation. Since these pre-insulated supports are used for high temperature pipes, PT&P used calcium silicate as insulation and hot dipped galvanized the steel as a rust inhibitor. Piping Technology and Products Inc. handled all logistics of the international shipment.

Do you require hot shoes for your plant or refinery? Let us price them for you today!

75 Hot Shoes for a Construction Project in New Hampshire

These pre-insulated hot shoes are manufactured from carbon steel and insulated with Firetemp® and Foamglas. Firetemp® is a structural insert designed to carry the load capacity of the pipe while Foamglas is fragile and can support temperatures of up to 900F. The hot shoes measure 19 long with the base of pipe at 6. They weigh between 58 lbs to 185 lbs. The pre-insulated shoes are designed to maintain the insulated pipes at a temperature for functionality.

Do you require hot shoes like the ones described above? Let us price them for you now!

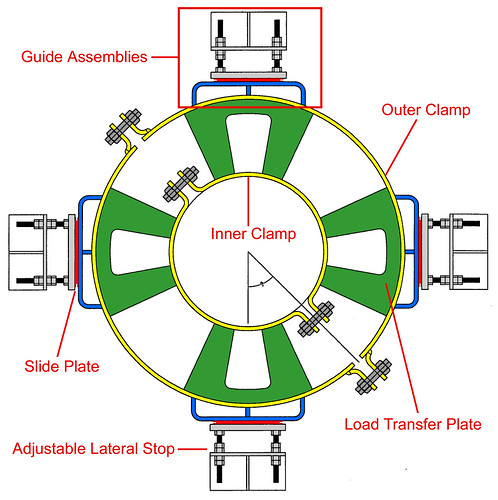

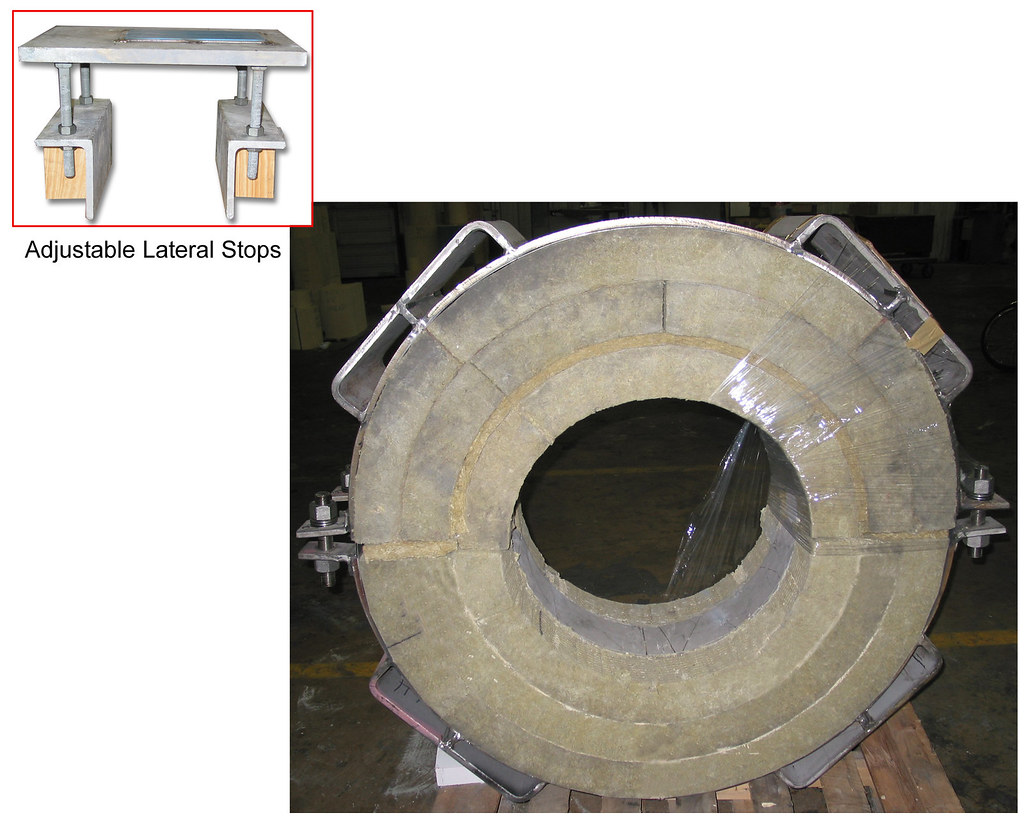

6000 lb. Load Hot Shoe with Adjustable Lateral Stops

Piping Technology & Products, Inc. recently assisted in the design and fabrication of a special hot shoe with adjustable lateral stops for an oil refinery in LA. The shoe assembly is designed to support loads up to 6000 lb. and to guide pipes that may reach up to 1200°F. The hot shoe consists of a 12 thick mineral wool insulation, an inner clamp surrounded by four load transfer plates, an outer guiding clamp, and four guide assemblies with PTFE, 25% glass filled, slide plates. The load transfer plates provide support and prevent damage to the insulation between the inner and outer guiding clamp.

The guide assemblies (comprised of the four guides on the shoe and the adjustable stops) are designed to account for lateral, vertical, and axial movement. PTFE, 25% glass filled, slide plates are used to minimize friction caused by movement between the shoe and the adjustable stops. The adjustable stops are fabricated from a 1 x 12 x 19 carbon steel plate with four rods and two angles. These allow for flexibility in adjusting the distance/gap within each guide assembly to control movement.

Want to learn more about hot shoes? Watch a pre-insulated support webinar now!

28" dia. Hot Shoes for a Natural Gas Plant

Piping Technology & Products, Inc. recently designed and manufactured twenty 28″ dia. Hotshoes (high temperature pre-insulated pipe supports) for a natural gas plant in Massachusetts. These supports are assembled with a 5″ thick high-density Calcium silicate insulation layer, in addition to stainless steel, Kaowool, and PTFE, 25% glass filled, slide plate materials. The supports are designed to support loads from 25 kips-50 kips at an operating temperature of 1800 degrees F. The shoes also allow for a travel of 7″ where applicable. PT&P also designed and fabricated rod hangers with variable spring supports for this project.

Do you have a need for hot shoes in your plant or refinery? Get pricing today!

51,000 lb. load Hot Shoes for a C4 Olefins Complex

Piping Technology & Products, Inc. designed and manufactured 44 shoes consisting of six guided and axial hot shoes, 10 guided hot shoes, and 28 sliding hot shoes. The materials used were calcium silicate, Marinite®, stainless steel plates, and PTFE, 25% glass filled. These shoes were designed for 8″ pipe with 7″ insulation with a load capacity of 5,100 lbs.

Do you require hot shoes in your piping system? Get pricing today!

Hot Shoes for a Chemical Plant in Texas

Piping Technology & Products, Inc. designed and manufactured 60 Marinite® hot shoes for a chemical plant in Texas.

These hot shoes are composed of Marinite®(high-density calcium silicate) and carbon steel. They were made for 8 NPS with 7 insulation. These shoes are used on steam lines, effluent lines, and any other process lines where it’s imperative that thermal energy is not lost through the pipe support. Tests were performed to show outer skin temperature at operating conditions.

Want to learn more about hot shoes? Instantly view a pre-insulated pipe support webinar today.

Insulated Pipe Shoes for Hot Applications

Piping Technology & Products, Inc. supplied both “hot shoes” for high temperature lines and “cold shoes” for cryogenic lines in this new plant. The shoes sit on the steel beams of the pipe rack and support the insulated pipe. The bottom photograph shows several of the shoes prior to shipment. The two large cold shoes in the foreground are lined with PUF (polyurethane foam) which functions both as an insulator and as a load bearing member at temperatures as low as –300oF. Hot shoes are lined with calcium silicate or Marinite® which can function up to 1200oF.

Do you need pre-insulated pipe shoes for your current or upcoming project? Get pricing today!

Dual Purpose Pipe Shoes for High Temperature Applications

The pictures above show insulated pipe supports designed for two very different temperature applications. The top picture shows an inspector checking “hot” shoes for high temperature piping. They have one 180 degree section of the insulation made of foam glass and the other 180 degree made from calcium silicate. Some components are chosen for their insulating properties only, other must both insulate and support the load of the pipe. The bottom picture shows a 54 inch “cold” shoe of galvanized steel with PTFE slide plates on the bottom. Inside the galvanized steel is bonded a layer of polyurethane foam which has been coated with a white vapor barrier. This polyurethane layer provides both insulation and support of the load at cryogenic temperatures.

Want to learn more about pre-insulated supports? Instantly view a recording of a past webinar!