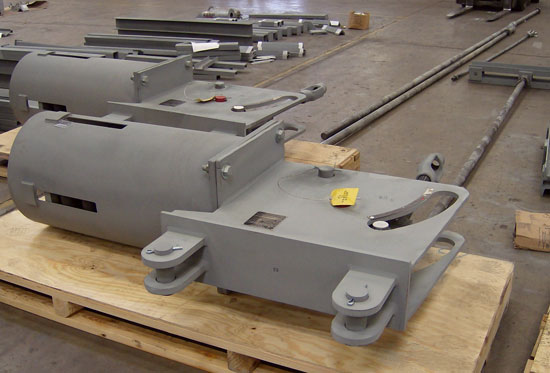

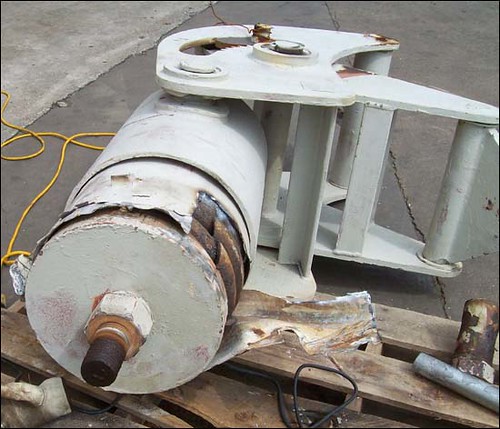

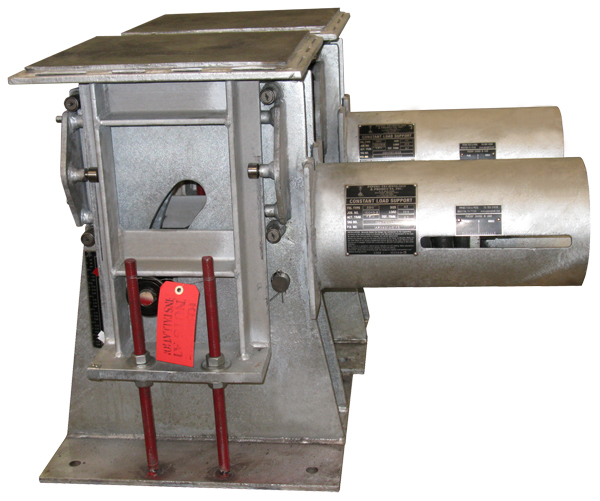

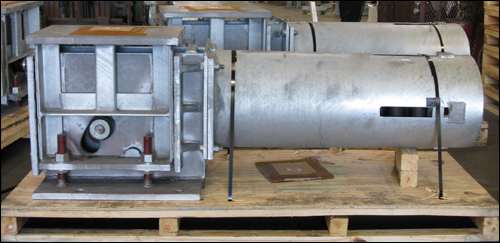

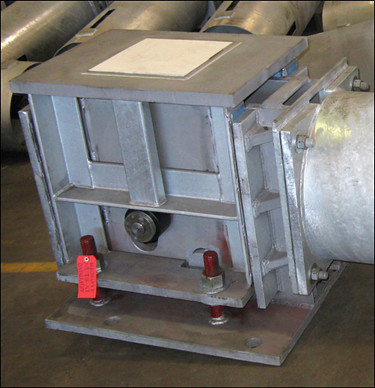

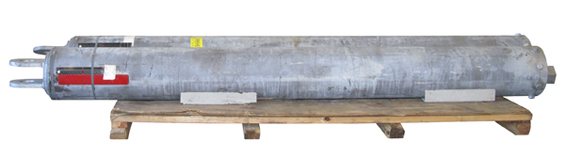

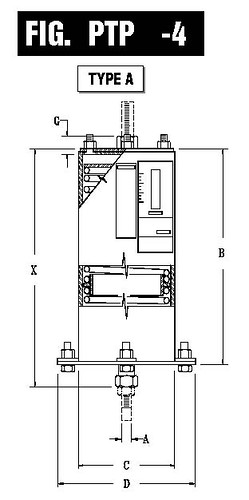

The constant spring hangers are manufactured from A36 carbon steel and have custom 4-bolt pipe clamps due to heavy loads. The dimensions are 40″ length x 18″ width x 85″ height and are designed for a 1,784 lb. load with 10″ of travel. The constants will be used to support radiant inlet manifolds and have a unique paint applied due to the highly corrosive condition. The entire pipe hanger assembly went through load and travel testing prior to shipping.

Want to learn more about constant springs? Instantly view a past constant webinar!