PT&P received a rush order for variable spring supports at 4:41 pm, quite late into the workday; however, this is business as usual, our manufacturing facility in Houston, TX operates 24/7 to support our customers.

|

|

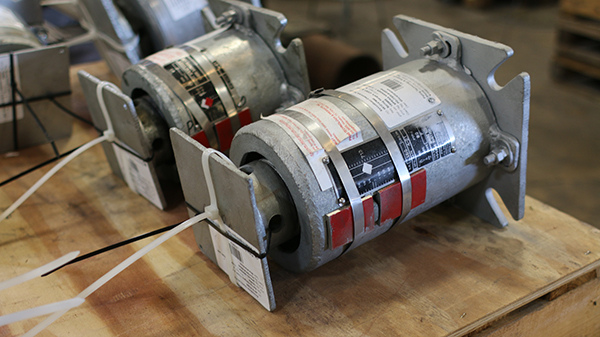

| In this case, the customer’s olefins plant was experiencing significant losses and urgently needed to replace the springs to resume operations. Seven variable springs were designed, fabricated, and shipped within just two days to minimize downtime.

The F-type variable spring support is designed to support piping from below, directly from the foundation, concrete column, or supporting structural pipe rack steel. Adjustment is made by inserting a bar into holes in the load column and turning the load column as a jackscrew. As global leaders in variable spring manufacturing, we leveraged our adaptive manufacturing processes, utilizing pre-fabricated in-house components that allow for quick assembly as soon as orders are placed. These variables were fabricated from carbon steel and hot-dipped galvanized for corrosion protection. They are designed to support loads ranging from 713 lb. to 1668 lb. and movements of 0.148″ to 0.133″. Load and travel tests, along with Q.C. inspections were performed before shipment. Variable springs are used in many applications that include: |

- Paper and Pulp Mills

- Petrochemical refineries for plastics, chemicals, polymers

- Renewable plants for solar, carbon black, hydrogen, blue ammonia, and biochar facilities

- Power plants for nuclear and fossil fuel power

PT&P REF. ORIGINAL POST 04132021