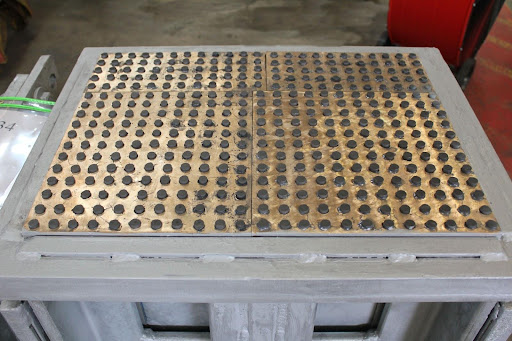

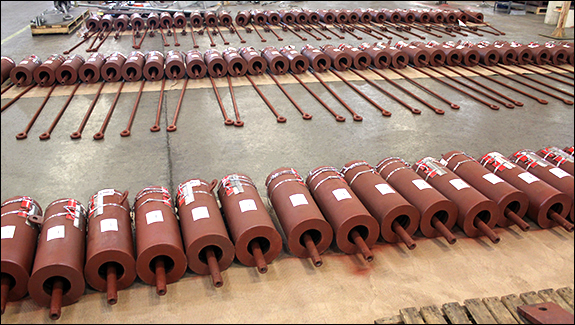

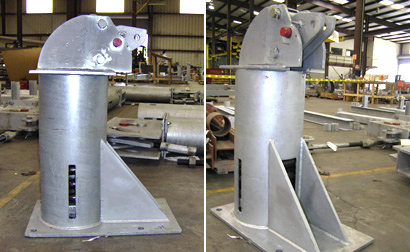

PT&P custom-designed constant spring support assemblies for a heat recovery steam generator at a combined-cycle power plant. These power plants utilize gas turbines, steam turbines, heat exchangers along with other components to make use of “exhaust waste” for a more efficient system. These 200-F Type constants were fabricated from A36 carbon steel and include a hot-dipped galvanized finish. The spring coils are formed from alloy steel and are neoprene coated. They are designed for an operating load of up to 886 lb., and up to 6″ of maximum travel. They are designed to be placed beneath the unit being supported and allow for movement in the vertical direction (up or down). The dimensions are 13″ W x 31″ L x 18-1/2″ H. Standard load and travel tests along with a quality control inspection were conducted prior to shipment. Since the mid-1970s, we have been working with power plants and have deep expertise in the evolution of power plant design over the last 40+ years, including the impact that it has had on Pipe Stress Engineering requirements. We have supplied products and services for a wide variety of power plants including Coal, Natural Gas, Biomass, Solar, Wind, Geothermal, Nuclear, and Hydroelectric. As the only major Global Provider of Expansion Joints, Engineered Pipe Supports, and Pipe Stress Engineering, we have the ability to provide unique solutions and solve the most challenging scenarios that may arise.

PT&P REF. ORIGINAL POST 01062021

Read More