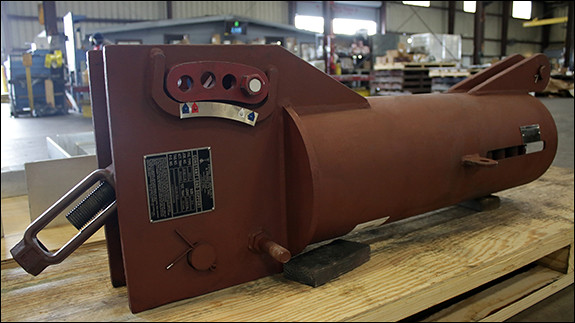

| Type: | B-Type Variable Spring Supports |

| Size: | PTP 100 & 200 | 3′ – 8′ ft. Height |

| Design: | 4,000 lb. – 17,000 lb. Loads |

| Material: | HDG Carbon Steel | Neoprene Coated Springs |

| Testing: | Standard Load Test | Q.C. Tests |

Piping Technology and Products, Inc. recently designed and fabricated B-Type variable spring supports for a plant in Texas. The operating loads range from 4,000 lb. to 17,000 lb. The variable springs are fabricated from galvanized carbon steel, have neoprene coated steel spring coils, and are designed to operate in environments up to 750°F. They have an overall height range from 3 ft. to 8 ft″. To ensure quality, standard load tests were performed prior to shipment.

Read More