The photograph above shows the entrance of the “Pipeline 2000” exhibit at Houston’s Museum of Natural Science

This part of the exhibit was fabricated by SWECO Fab, Inc. a division of Piping Technology & Products, Inc. of Houston, Texas.

Read More

The photograph above shows the entrance of the “Pipeline 2000” exhibit at Houston’s Museum of Natural Science

This part of the exhibit was fabricated by SWECO Fab, Inc. a division of Piping Technology & Products, Inc. of Houston, Texas.

Read More

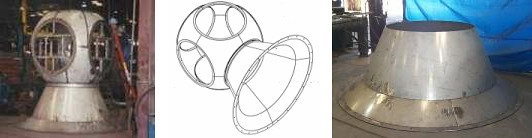

Sweco Fab, Inc., the ASME CODE fabrication subsidiary of PT&P, built the forward section of an International Space Station service module for NASA in Fall, 1999. The main purpose for the full-scale mock-up service module will be to replicate the International Space Station for use in astronaut training at NASA’s Neutral Buoyancy Lab (NBL).

The Neutral Buoyancy Lab, located at the Sonny Carter Training Facility near NASA Houston Johnson Space Center (JSC), is a large pool of water used in astronaut training to simulate the gravity conditions in space. The forward section manufactured by Sweco Fab, Inc., a wholly owned subsidiary of Piping Technology & Products, is made up of ASTM A-304L material and weighs approximately 2500 lbs. The unit was on display at NASA’s Inspection Day 1999 and will soon be employed in International Space Station astronaut training.

Read MoreSweco Fab, Inc., PT&P’s ASME code pressure vessel shop, is building its third order for stainless steel tanks used to transport diesel fuel to off-shore platforms by helicopter. Special calculations were required to verify the air-worthiness of the skid-mounted tanks.

Do you need a vessel for an upcoming project? Get pricing today!

Pictured above is a deaerator built by Sweco Fab, Inc. and is destined to go into service for one of the larger chemical companies at their Plaquemine, Louisiana Fields.

The upper vessel shown is a 120” diameter 304L stainless unit connected to a 144” carbon steel storage tank of approximately 38,000 lb.

Do you require a tank or vessel for an upcoming project? Let us price it for you today!

Sweco Fab, Inc. designed and fabricated a complete duct system for a major engineering and construction firm in Houston.The project is a carbon dioxide facility for a food processing plant being constructed in Massachusetts.

Two unique features of the 96” ID fabrication are the very light materials with close tolerances and the painting system for food grade product.

Do you have a need for a duct system? Get pricing on a duct system today!

The picture above shows two views of launcher-receivers loaded on a truck. These devices are installed in pipelines to launch and receive pipeline pigs. Pigs can be used for cleaning or for separation of two products in the same pipeline. Modern pigs with sensing devices are used in old pipelines to look for damage or corrosion problems. These launcher-receivers part of several being built by the SWECO Fab, Inc. division of Piping Technology & Products, Inc. for a large MTBE plant in Saudi Arabia.

In need of some pig launchers and receivers for an upcoming project? Let us price one for you today!

The photograph above shows a computer-controlled bank of gas torches used to burn patterns of small components from large metal plates. The geometry of the components is used to program the computer. The metal plate is on a “water table” which catches the melted material to be utilized in the national program to conserve natural resources.

Piping Technology & Products, Inc. supplies hardware, pipe supports, expansion joints and other fabricated items for petrochemical, paper and electric power plants throughout the U.S. and overseas.

Want to learn more about our various products? Visit our webinar archives today!

Sweco Fab, Inc., a wholly subsidiary of Piping Technology & Products, Inc., and an ASME and API code vessel shop recently unveiled their design of a wet air fan cyclone for a new high density polyethylene project.

The barrel, which is a twenty-one feet long, tapers upward from a twelve-inch diameter base to a six foot diameter top. Ears on the exterior of the barrel are provided for support and alignment. Air inlet is designed to mate with other components forming part of the process equipment. The fan cowling has outboard ears to facilitate ease of test, assembly and maintenance. The cyclone was rolled and formed from ¼ inch carbon steel and weighs 4,000 lb.

Want to learn more about Sweco Fab, Inc.? Visit out webinar archives!

The picture above shows special components of today’s piping systems. At the top are two rings with machined surfaces required to help seal the system when operating at high pressures. Rings and spacers can be fabricated from a variety of metals including carbon steels, stainless steels, alloys such as Inconel®, Hastelloy or Titanium. The choice of materials depends on the temperatures and pressures the system is designed for. Holes can be drilled to produce bleed rings which relieve pressure slowly. The above picture shows orifice plates which are made from the same materials.

Need orifice plates? Get pricing for them today!

Pictured above is one of the six identical tanks Sweco Fab, Inc. supplied for the expansion of City of Houston’s Sims Bayou Waste Treatment Plant.

These carbon steel tanks are rubber lined and have a special paint outside. Each tank has 6,000 gallon capacity.

Do you require ASME pressure vessels or tanks? Let us price them for you today!