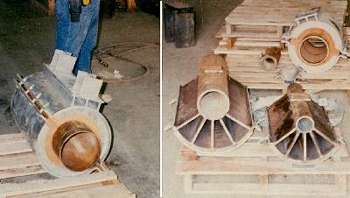

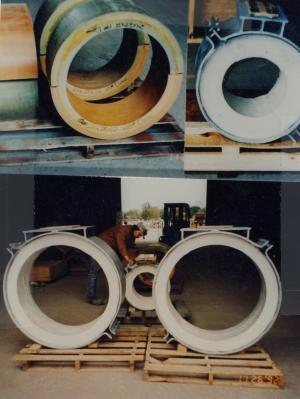

Piping Technology & Products, Inc. designed and manufactured 250 variable sized cold shoes for a chemical plant in Texas.

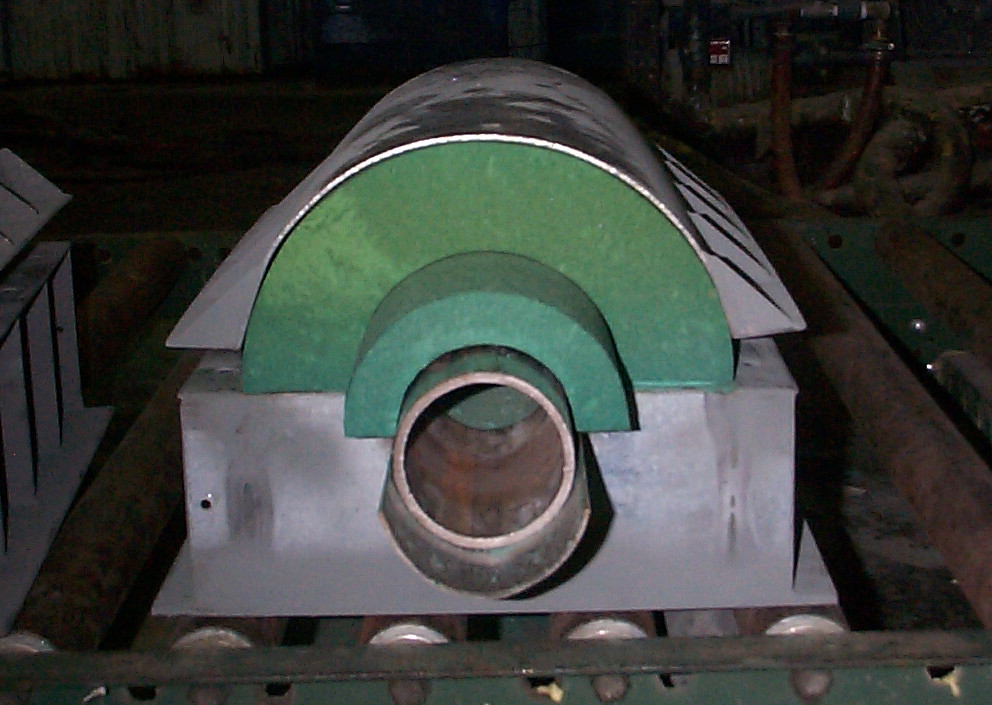

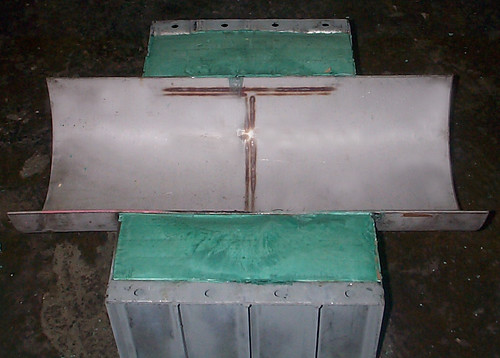

These cold shoes are designed for cryogenic (low temperature) pipelines where direct contact with the pipe cannot be made. These shoes come with two pieces, top and bottom, and are made of polyurethane foam. They are then wrapped in vapor barriers, covered with a protective shield and placed in a pipe saddle.

Want to learn more about cold shoes? View a pre-insulated pipe support webinar today!