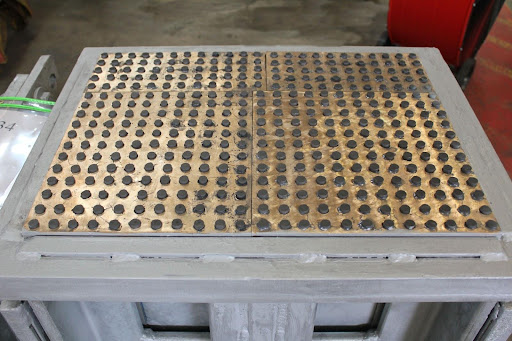

These big-ton constant spring supports with Bronzphite® slide plates were designed for a 400 KTA light oil processing and utilization unit in Southeast Asia. The constants are designed for high loads and utilize self-lubricating bearing plates consisting of high-quality bronze and graphite-filled grooves. Bronzphite® can be used where temperatures are up to 1100°F and for high loads, low-velocity applications, and in places where the use of oil or grease is undesirable or unfeasible.

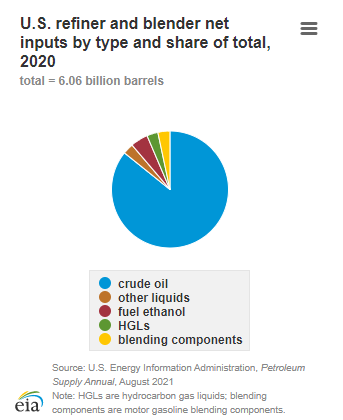

PT&P custom-designed and manufactured a total of four big ton constant spring supports w/ Brozphite® slide plates for a 400 KTA light oil for a processing and utilization unit at one of the largest of largest oil refineries in China. In US refineries, crude oil still makes up a majority of what is produced today:

These constant assemblies were fabricated from carbon steel and hot-dipped galvanized for extra protection against corrosion. The bronze plate acts as the bearing surface, supporting heavy loads, while the graphite inserts provide a solid, oil-free sliding surface. They are designed for operating temperatures up to 1100°F and an operating load of 187,393 lb., with 1-1/2″ total travel. It is through the combination of high-strength bearings and impregnated graphite that it is an ideal environment for maintaining excellent wear resistance and durability under severe operating conditions. Load and travel testing was performed prior to shipment.

For this particular crude oil production and mining facility, we also supplied other key products from our portfolio, including variables, snubbers, sway braces, and sway struts. Petroleum refineries change crude oil into products such as jet fuel, gasoline, polypropylene, polyethylene, propane, sulfur, carbon black feed, and diesel that can be used for transportation, heating, feedstocks for making other chemicals, generating electricity, renewable energy, and paving roads.

As an industry leader in the oil, gas, and petrochemical industries for over 47 years, we specialize in designing pipe supports, expansion joints, and insulated supports for unique applications involving both products readily available and products not readily available. Our products are used in the CDU (crude distillation units), hydrocracking units, RFCC (residual fluid catalytic cracking), naphtha hydrotreater, hydrodesulfurization units (also known as alkylation units), and sulphuric acid regeneration (SAR) units in refineries.

PT&P REF. ORIGINAL POST 09252017