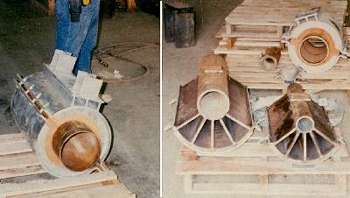

The photographs above show insulated pipe supports designed for a system being installed in a very cold climate in Russia. The insulating components are inside next to the pipe. The outside components are galvanized steel. In the foreground of the photo at the right are two fixtures which were built for load testing these pipe supports by applying known forces with a hydraulic load cell. Piping Technology & Products, Inc., fabricated prototype units for a Houston Engineering Firm and tested the units. After successful tests a number of similar units were built for shipment to Russia.

In need of some new insulated pipe supports? Let us price one for you today!