PT&P custom designed pipe hanger and clamp assemblies for a flue-gas desulfurization application in an energy facility located in Kansas. The assemblies are designed for pipes ranging in size from 2-1/2″ to 6″ in diameter, and are capable of a 650 lb. operating load. Materials include tube steel, fig. 92 washer, fig. 122 all threaded rod, fig. 30 turnbuckle, fig. 40 weldless eyenut and fig. 70 pipe clamp.

Read MoreBlog

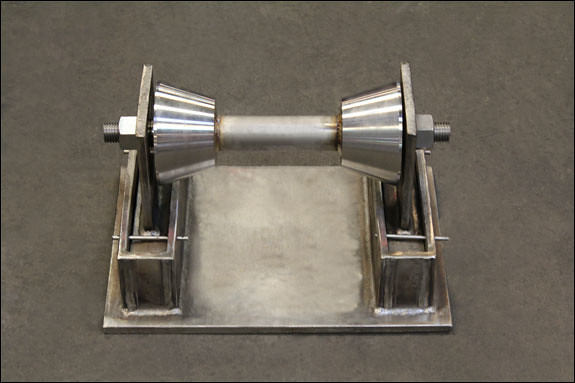

Stainless Steel Roller Stands Custom Designed for a Wastewater Treatment Plant

June 8, 2015

PT&P designed spring loaded stainless steel roller stands for a wastewater treatment plant. The rollers were custom designed for ease of assembly to support a 30″ diameter pipeline. They include eight springs in two spring housings and are designed for 1,000 lb. load. The base plate is 18-3/4″ x 13″ and the BOP is 10-3/16″. Roller stands are used to support pipelines that expand and contract longitudinally in the axial direction and where vertical adjustment is not necessary.

Read More