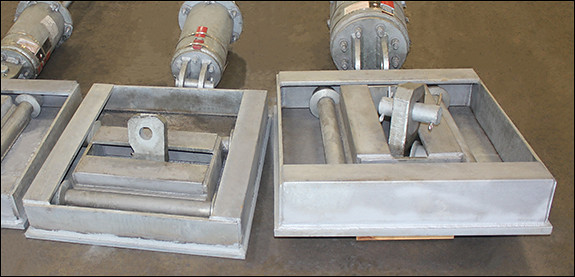

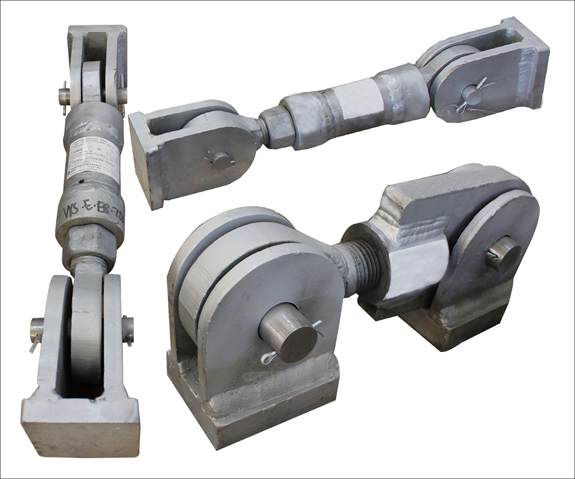

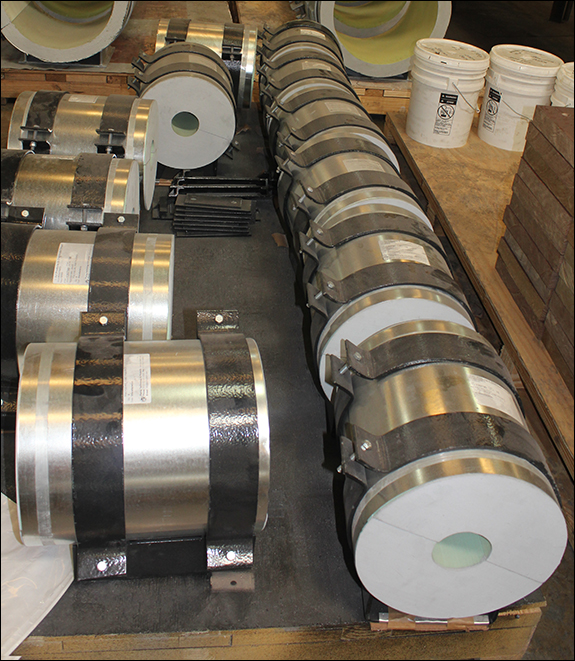

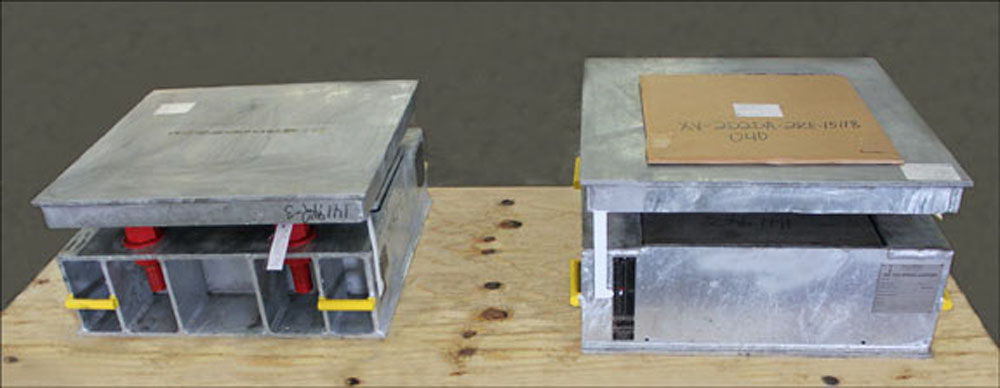

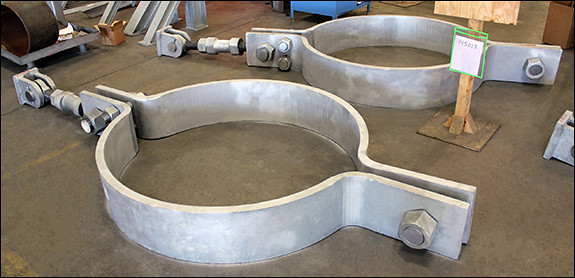

| Type: | Variables with dual travelers |

| Design: | Operating load: 1,698-21,756 lbs |

| Material: | A36 Carbon Steel with HDG finish |

| Size: | Horizontal Travelers range from size 2 to size 4 |

These dual travelers with Type-C variable spring hanger assemblies were custom designed by Piping Technology & Products for valves in a de-coker unit in Texas. All completed assemblies were fabricated from A36 carbon steel with an HDG finish. The travelers range from size 2 to size 4 and are designed for 12″ of horizontal movement. The variables are designed for an operating loads ranging from 1,698-21,756 lbs.

Read More