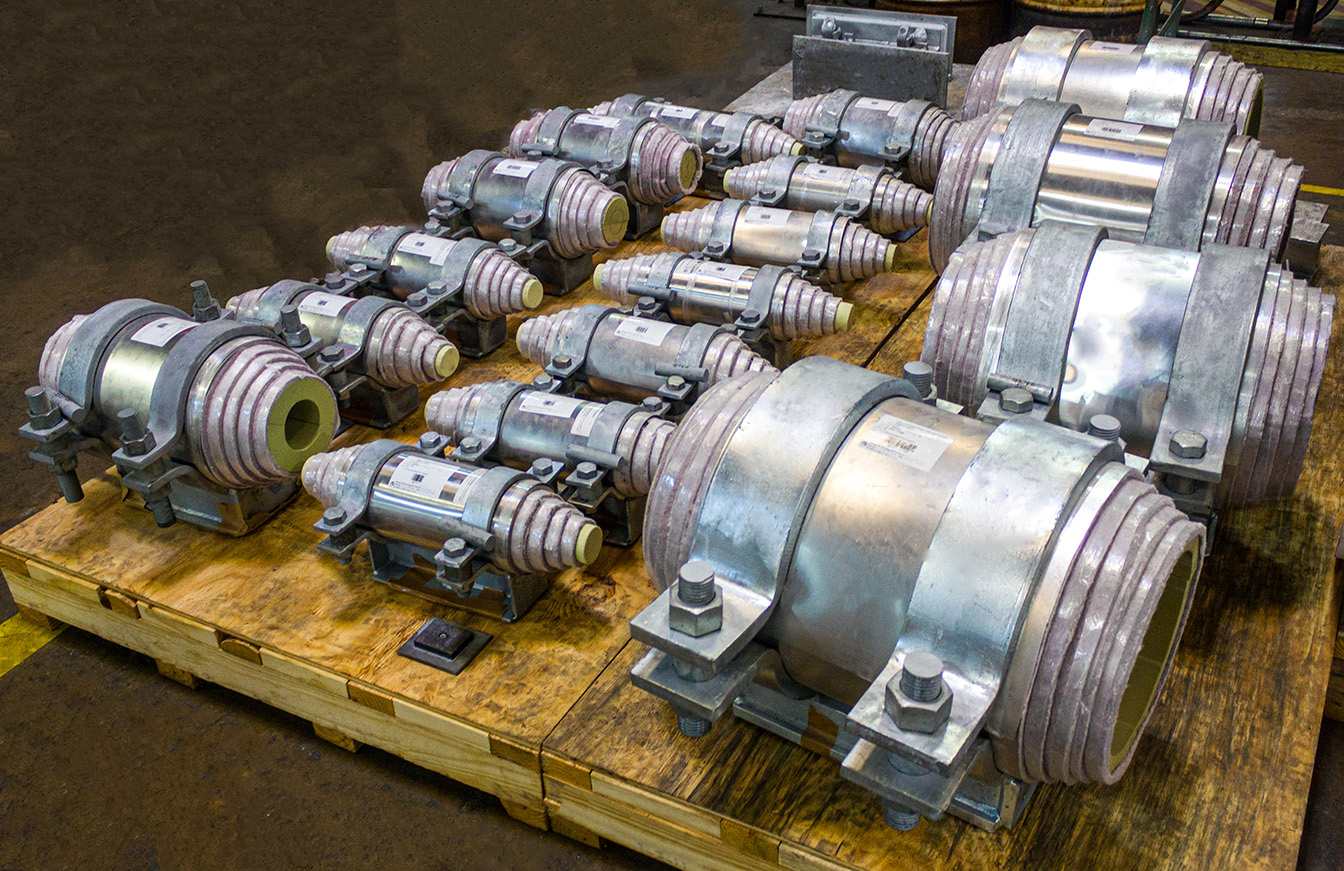

Sweco Fab, Inc., a division of PT&P, fabricated a variety of spectacle blinds for a leading solutions provider. The spectacle blinds are fabricated from A516-70 carbon steel and coated with PTFE, 25% glass-filled material. The pipe sizes ranged from 2″ to 20″ diameter and all blinds were fabricated per ASME B16.48 code. The function of a spectacle blind is to allow a line to be in either full shut-off mode or full flow mode, depending on which side is being utilized.

Spectacle blinds can be made of various materials such as carbon steel (ASTM A105), stainless steel (ASTM A182 F304, F304L, F304H, F316, F316L), alloy steel (ASTM A182 F1, F11, F22,), duplex Stainless steel (UNS S31803, UNS S32750), nickel alloys (Monel 400 & 500, Inconel 600 & 625, Incoloy 800, 825, Hastelloy C22, C276), and copper alloys (copper, brass & gunmetal). PT&P has manufacturing capabilities to handle multiple materials in our facility and our engineering teams have deep experience in designing with them (View section on Metallurgy).

In this application, the line blinds and spacers are coated with Fluoropolymer Coatings which allow for lubrication and controlled friction, wear resistance, heat resistance, nonstick and release properties, and corrosion protection. The coating enables a smooth, hard, slick coating that provides excellent corrosion and chemical resistance. Other benefits of fluoropolymer coatings include reduced friction, resistance to galling, non-stick, non-wetting, electrical resistance, and abrasion resistance. Spectacle blinds are a lower-cost alternative to double block and bleed valves where OSHA requires positive isolation of piping segments for safety reasons. Spectacle blinds are installed in the inlet and outlet of static and rotary equipment, in bypass lines, at unit battery limit, and where double isolation is required for high-pressure lines.

Read More