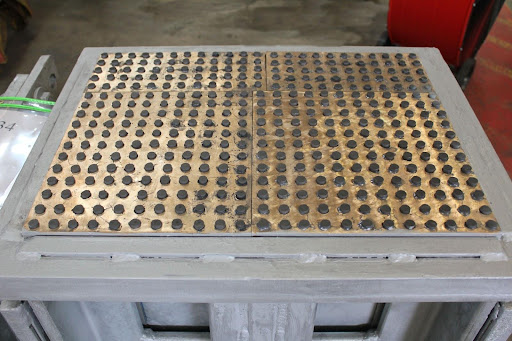

These clamps were installed in a coal-fired power plant on the Ohio River and this plant features one of the largest smokestacks in the world at 1038 feet. For this plant, sub-bituminous coal is used in conjunction with steam turbine technology to generate thermal power with over 10k Gigawatts of output annually.

Heavy-duty pipe clamps are bolted around the pipe and connect to the remainder of the pipe hanger assembly. This assembly included a Fig. 30 Forged Turnbuckle, which is also available on Amazon as a stocked item. PT&P maintains an extensive inventory of pipe clamps required for pipe hangers and support assemblies. These Fig. 80 Three-Bolt Pipe Clamps are fabricated from carbon steel and for this project, the pipe clamps were painted with a red oxide primer. These pipe clamps are designed for 36” diameter pipelines and are recommended for suspension of cold pipelines or hotlines where little or no insulation is required and are capable of supporting both horizontal and vertical piping. A visual inspection test along with “sample pipe” dimensional checks were conducted prior to shipment.

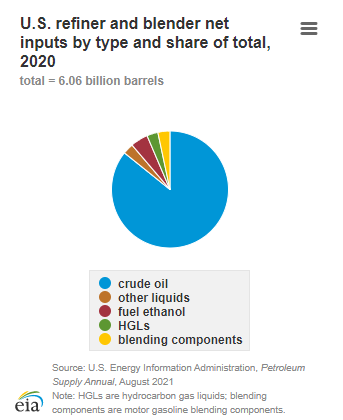

Such clamps can be used in any type of piping system for various industries such as chemical, biofuel, food processing, and refining plants. We have the ability to get such products at your jobsite overnight given our pipe hanger hardware inventory of over 1 million pounds, our quick order system through Amazon, and 24/7 manufacturing and engineering support provided by our teams around the clock.

Do you need this exact pipe support? Skip the line and order our Standard Pipe Support Components on Amazon. From forged carbon steel turnbuckles and light or heavy 2-bolt, 3-bolt pipe clamps, riser clamps to long tangent u-bolts, we stock standard sizes for your quick-turn orders.

Read More