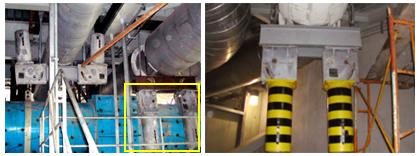

Piping Technology & Products, Inc. designed and manufactured special vertical type E constant spring supports for a power plant. These were designed and installed as pairs in a configuration similar to the typical G type constants. The advantage of using a pair of the special E rather than the conventional G type is that the total width is smaller as can be seen in Figure 1.

The constants were designed to support loads from 5,730 lbs to 10,690 lbs. They were fabricated from A36 Carbon steel. The dimensions of the individual constants are 60″ high, 16 1/2″ long, and 14″ in wide. The size of the supported pipe determined the width of the assembly. As with all constants built by PT&P, they were tested to verify that standard specifications for variation of load over the full range of travel were met.

Do you need constant spring supports for an upcoming project? Request a quote today!