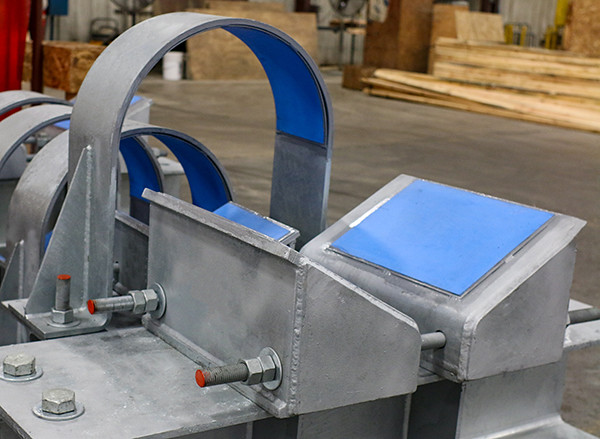

These hold-down pipe clamp assemblies are specially fabricated and include wedges with 25% glass-filled PTFE to absorb vibration and also serve as a buffer between the steel pipe and pipe support. Vibration can occur in Power, Solar, Biofuels, and Chemical plants because of flow-induced and/or acoustic-induced vibration due to the flow of fluids or gas/steam through the piping system. Similarly, vibration can occur in pipelines near rotating equipment such as reciprocating pumps and compressors resulting in pulsations or mechanical forces that can occur in both onshore or offshore production facilities. Vibration can be strong enough to cause premature failure or cracks resulting in unplanned shutdowns. These units shown in the photograph are custom-designed for pipe sizes up to 20″ in diameter and temperatures up to 200°F and can be adjusted to accommodate a range of heights for the T.O.S to the B.O.P. They are 21″ wide x 26″ long x 23″ high and are proven to greatly reduce vibration to acceptable levels. These hold-down pipe clamps are fabricated utilizing A 36 carbon steel plate and A 307 Gr. All-threaded rods. All components were hot-dipped galvanized and a quality control inspection was performed before shipment.

Live New Webinar

Sign-up for a Live Technical Webinar…

Shock Control, Restraint & Support Devices Webinar

Date: Thursday, May 1, 2025 - Register for 10:00 am OR 2:00 pm

*Note: Time Zone is CDT * Central Daylight Savings Time / GMT -5h

Live Webinars are 1 PE/PDH Credit for TX Professional Engineers

Explore the various applications of snubbers, sway braces, and sway struts in piping systems and equipment. Learn how these products help prevent pipe system failure due to seismic loads, flow transients, wind loads, safety valve thrust loads, or pipe rupture. Discover the various tests performed within PT&P’s facility to ensure product quality, including cycle testing, travel testing, and load testing. Finally, view the value-added services offered by PT&P and rest assure that your shock control, restraint, and support device needs can be covered by our 24×7 web-based emergency services, field services, and quick turnaround time when you need it most.

Upcoming Webinars:

May 8th: U.S. Bellows - Expansion Joints In-depth Webinar 10:00 am OR 2:00 pm

May 15th: Pipe Support Engineering & Design Webinar 10:00 am OR 2:00 pm

May 22nd: Fabric Expansion Joints Webinar by U.S. Bellows, Inc. 10:00 am OR 2:00 pm

Online Course

Piping Design and Analysis Influence on Pipe Support Selection and Design

Surveying a piping system? Need to change a current system?

This course is also great for…

• New Engineers, Management and Operations

• Field, Process, Maintenance and New Engineers

• Piping and Piping System Designers and/or Instructors

*This online course is approved for 8 hrs. P.E. Credits