PT&P designed U-Type constant spring supports for an LNG plant in Canada. These are horizontal constants designed to support piping from below where the base plate is bolted directly to the top of the steel or the foundation using anchor bolts. These specific constant springs are designed to support an operating load of 67,420 lb. with 6″ of total upward travel. The constants are fabricated from galvanized carbon steel for protection against corrosion. Standard load and travel testing were completed to ensure the quality and performance of these constants.

U-Type constant springs are commonly used in industrial applications where there is a need to support pipelines, ducts, or other structures subjected to thermal expansion or contraction. These springs are designed to provide a constant supporting force over a defined range of movement, typically in response to temperature changes. Here are some specific applications where U-Type constant springs might be used:

- Piping Systems: In industrial plants, refineries, chemical processing facilities, and power plants, pipelines are often subjected to temperature fluctuations due to the flow of hot fluids. U-Type constant springs can be employed to support these pipelines and compensate for thermal expansion or contraction, preventing excessive stress on the piping system.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems often involve ductwork that expands and contracts with changes in temperature. U-Type constant springs can be installed to support HVAC ducts and accommodate thermal movements, ensuring structural integrity and preventing damage.

- Steam Systems: Steam distribution systems in industries such as power generation, food processing, and manufacturing also require support for piping subjected to thermal expansion. U-Type constant springs are used to maintain proper alignment and support in steam piping systems, preventing issues such as pipe stress and misalignment.

- Oil and Gas Pipelines: In the oil and gas industry, pipelines are essential for transporting crude oil, natural gas, and petroleum products over long distances. U-Type constant springs help support these pipelines and compensate for temperature changes, ensuring the reliability and safety of the transportation infrastructure.

- Process Equipment: Various types of process equipment, such as reactors, heat exchangers, and vessels, experience thermal expansion and contraction during operation. U-Type constant springs may be employed to support and compensate for the movement of such equipment, reducing the risk of damage and prolonging service life.

U-Type constant springs play a crucial role in maintaining the structural integrity and reliability of industrial systems and equipment subjected to thermal expansion or contraction.

Constant springs are sometimes installed near rotating equipment such as pumps and compressors used in manufacturing, mining operations, utilities, oil and gas extraction, and cross-country pipelines. By providing constant support to piping leading to rotating equipment subject to both vertical and horizontal movement, these types of spring hangers help to decrease stresses imposed on rotating equipment, thereby extending the life of the bearings and seals within these units.

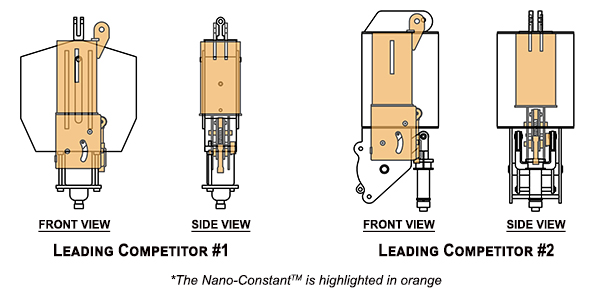

In our continued efforts to meet projects needs for operationally best in class design with the lowest cost and time to market we created the world’s smallest constant spring support.

|

| We have designed and built constants for not only refineries, LNG, geothermal plants, petrochemical plants, and renewable energy facilities. The use applications include coker replacement, debottlenecking of furnace operations, installation of a new VDU (vacuum distillation unit) heater, tube, and heater replacement, and flare gas recovery units where the installation of constant spring hangers helped to improve the efficiency of the system or process.

Constant spring supports alongside our portfolio of products are shipped worldwide from our Houston, Texas headquarters, where all our products are manufactured. We are open for plant tours. If you are interested, please let us know so we can schedule some time with your team. |

PT&P REF. ORIGINAL POST 05102016

Read More