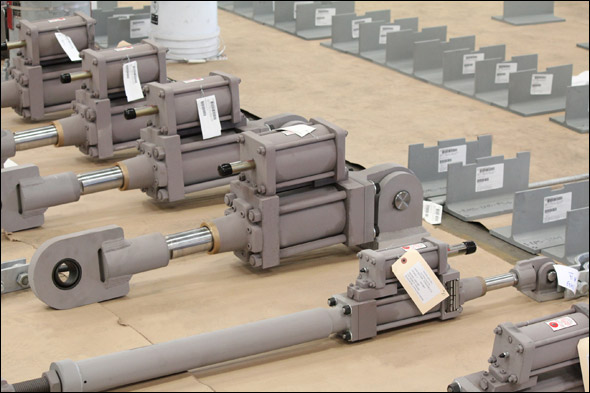

Fronek Anchor/Darling Enterprises, a division of PT&P designed and fabricated hydraulic snubbers for a geothermal facility in California. The Fig. 510 AD snubbers ranged in size from 34-3/4″ to 37-5/8″ piston-to-piston and were designed for a 50,000 lb. maximum load, 5″ cylinder size and a 6″ stroke. The Fig. 511 AD snubbers ranged in size from 56-15/16″ to 59-5/16″ P-P and were designed for a 20,000 lb. maximum load, 2-1/2″ cylinder size and a 6″ stroke. Hydraulic snubbers are designed to protect the piping system when a sudden, heavy load is applied (such as an earthquake of high intensity), which can cause serious vibrations leading to complete destruction. A custom three-bolt pipe clamp fabricated from carbon steel was designed to fit in a limited space. A cycle test throughout the full stroke from zero to fully extended was performed prior to shipment.

Live New Webinar

Sign-up for a Live Technical Webinar…

Engineered Spring Supports (Practical, Hands-on Approach) Webinar

Date: Thursday, December 19, 2024 - Register for 10:00 am OR 2:00 pm

*Note: Time Zone is CDT * Central Daylight Savings Time / GMT -5h

Live Webinars are 1 PE/PDH Credit for TX Professional Engineers

Learn how the theoretical applications of spring supports are put into use in the real world. We will start with a review of the working principles of both variable and constant springs. See how brand new spring looks at delivery, and review installation guidelines. Learn the key points to review through the total installation process and subsequently when the springs are in operation. See how to determine if springs need adjustments, re-calibration, refurbishment, or replacement. View in field examples, shutdown, and isolation procedures. See the selection process required when there are significant changes to the operating condition.

Upcoming Webinars:

December 26th: Pipe Support Engineering & Design Webinar 10:00 am OR 2:00 pm

Online Course

Piping Design and Analysis Influence on Pipe Support Selection and Design

Surveying a piping system? Need to change a current system?

This course is also great for…

• New Engineers, Management and Operations

• Field, Process, Maintenance and New Engineers

• Piping and Piping System Designers and/or Instructors

*This online course is approved for 8 hrs. P.E. Credits