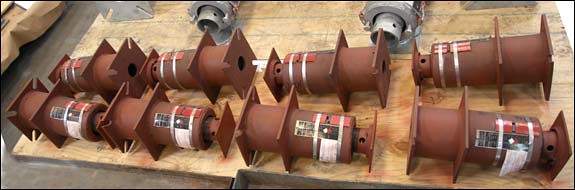

| Type: | F-Type Variable Spring Supports (Furnace Springs) |

| Material: | Carbon Steel | Red Oxide Primer |

| Design: | Movement: 1/2 “| Load: 398 lb. | Spring Rate: 84 lb./in. |

| Testing: | Standard Spring Rate & Calibration Tests |

PT&P designed and manufactured these F-Type variable spring supports for use in a furnace at a facility in Trinidad. We manufactured these furnace springs for an operating load of 398 lb., a movement up to 1/2″, and a spring rate of 84 lb./in. Customer specifications required a modified “installed height” while maintaining the spring rate, operating load and installation load. In order to accomplish this, PT&P designed, manufactured, and attached, to each spring, a “pedestal” to accomplish the increased installed height. They are fabricated from carbon steel with a red oxide primer coating (instead of a hot dipped galvanized) to protect against corrosion. Our standard hot-dipped galvanizing is not suitable for high temperatures because the zinc used in the galvanizing process can melt and cause damage to surrounding pipes and equipment. We also offer several other coatings for high-temperature applications.

We offer a wide range of modifications to our standard variable springs, from stainless steel units used in Food Processing plants and facilities which operate at Sub-Zero temperatures to units designed for use in high-temperature applications often found in refineries, fertilizer, and chemical plants. Some applications include hydrogen reboilers and radiant coils in gas vent heater systems. Our team of sales, engineering, and manufacturing offers a unique source of experience and knowledge unmatched in our industry.

In a Furnace application, both variable and/or constant spring hangers are utilized to support piping and equipment. In the past year, we have provided constant furnace springs for some of the largest refineries in the Americas. We replaced a 25-year incumbent design with a smaller envelope at a lower cost than any other offering in the market with our newly designed nano-constant. The project requirements were stringent in terms of load deviation requirements of 3% of all catalyst tube springs. We provided over 350 furnace springs in less than six months’ time from our manufacturing facility in Houston, Texas. To expedite the manufacture and shipment of springs, we built a new test machine in order to conduct tests more quickly, as every unit is tested before being shipped to the job site.

If you need assistance or are interested in scheduling a virtual or in-person training specifically on pipe supports and expansion joints for furnace applications, reach out as we are always available 24×7 via our emergency service or just send an email to info@pipingtech.com.

PT&P REF. ORIGINAL POST 02212017