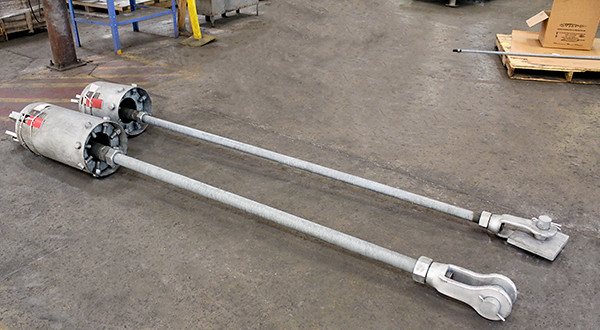

| Type: | B-Type Variable Spring Support Assemblies |

| Size: | 13″ to 120″ range pipe elevation |

| Design: | Operating Loads: 9,320 lb. to 28,2000 lb. Spring Rates 4,700 lb./in. & 5,320 lb./in |

| Material: | | Hot-dipped Galvanized Carbon Steel |

| Testing: | Load & Travel Test | Q.C. Inspection |

These variables were supplied to an overseas LNG facility where accessibility is limited due to the remote location in the facility as well as the plant itself. Products shipped must be very dependable and long-lasting because of the difficulty of shipping to this location. Variables use coiled springs to support a load and allow movement. The resistance of the coil to a load change during compression, which is why these devices are called “variables”. We offer a variety of different designs of variable spring pipe supports. PT&P with its long-standing history and experience has set up optimized manufacturing to offer an unparalleled set of customization options with minimal impact on delivery timeframes to support JIT deliveries and help manage cash flows on such large capital-intensive projects. In addition to our standard (hot-dipped galvanized, neoprene coated spring coils) variable spring supports, we can customize our springs to accommodate special materials, finish, dimension, load, load adjustment, travel, and travel stops, as well as provide sensors for remote monitoring.

Given the shift in global LNG production due to volatile political situations outside the US, the US has become the largest exporter of LNG this year globally. US LNG exports will continue to grow because of increased LNG export capacity, increased international natural gas and LNG prices, and increased global demand, especially in Europe.

During the initial build out in LNG globally in the late 1990s/early 2000s, PTP provided the platform to its customers and their clients for extensive innovation concerning all phases of development concerning pipe supports for LNG plants and terminals starting with product design, testing, material, and climate considerations. As the “thought leaders” in product design, we helped develop and produce the now most commonly used cryogenic supports utilizing G-10 insulation. As LNG capital projects return to the US, you can count on PTP to provide an unparalleled track record and expertise to move your LNG projects along safely in a timely cost-effective manner to meet world energy needs.

PT&P REF. ORIGINAL POST 04072020