Precision-Engineered Cryogenic Pipe Supports

When dealing with cryogenic piping systems, thermal isolation is more than a preference, it’s a necessity.

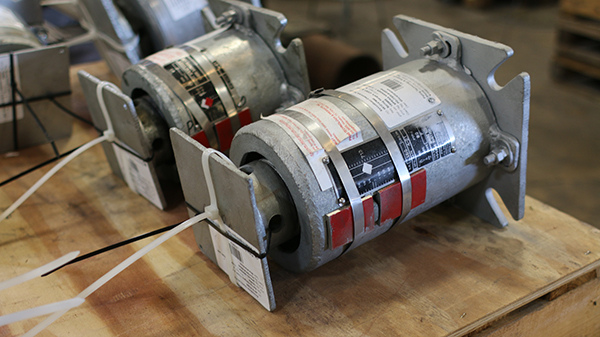

That’s where cold shoes come in. Cold shoes are specialized pre-insulated pipe supports designed to prevent the transfer of extreme cold from the pipe to surrounding structures.

These supports are critical in preserving structural integrity and ensuring safe operation in cryogenic environments, withstanding temperatures as low as -300°F.

At Piping Technology & Products, we manufacture cold shoes with high-density polyurethane foam (PUF) insulation. Known for its superior thermal resistance, low weight, and adaptability, PUF is ideal for minimizing heat transfer while maintaining structural support.

Built for Extreme Conditions — and Big Pipelines

In a project for a Liquefied Natural Gas (LNG) facility in Mozambique, we fabricated a series of custom-designed cryogenic pipe supports engineered for performance in high-demand applications.

Key Product Specs:

- Pipe Diameters: 30″ to 72″

- Support Dimensions: 45″ to 88″ high, 42-1/2″ to 85-1/2″ wide, 28″ to 33″ long

- Insulation: 5″ to 6″ thick high-density polyurethane foam

- Materials: Carbon steel with hot-dip galvanized finish; aluminized steel jacket for vapor barrier

Polyurethane foam insulation (PUF) was selected for its reliability under thermal stress and ability to be customized to various pipe sizes.

Our in-house engineering and fabrication capabilities allow us to deliver high-performance supports that meet exact project specifications while minimizing installation and maintenance issues.

Designed for the LNG Industry

LNG facilities demand exceptional durability, reliable thermal performance, and insulation systems that prevent heat ingress into cryogenic pipelines. Without proper cryogenic pipe supports like cold shoes, LNG systems face a range of serious challenges:

- Boil-Off Gas (BOG): Heat ingress can cause LNG to vaporize, leading to pressure buildup and product loss.

- Frost and Ice Formation: External surfaces can ice over, causing structural stress and safety hazards for workers.

- Material Embrittlement: Non-cryogenic components may crack or fail when exposed to ultra-low temperatures.

- Increased Energy Use: Systems become less efficient, requiring more power to maintain cryogenic conditions.

- Environmental and Safety Risks: Uninsulated lines can leak LNG vapor, potentially forming flammable gas clouds.

These issues drive up costs, introduce safety concerns, and reduce system reliability.

From small-bore lines to massive pipe systems like those in this project, our cold shoes are engineered to prevent these outcomes at LNG operating plants.

With high-density PUF insulation and heavy-duty construction, they support large-diameter lines while minimizing thermal transfer, resisting corrosion, and protecting the integrity of LNG infrastructure.

Beyond Cold Shoes: Full-Scope Support for LNG Projects

Piping Technology & Products is more than a manufacturer—we’re a project partner. In addition to cold shoes, we offer a comprehensive suite of products commonly used in LNG and other cryogenic applications:

-

-

- Single Pipe Expansion Joint

- Micarta® & Insulated Supports

- Slide Bearing Plates

- Snubbers, Sway Braces & Variable/Constant Spring Assemblies

- Flanges, Strainers & Bleed Rings

- Fabricated Pipe Shoes, Anchors & Guides

- Hold-Down Clamps & Misc. Steel Fabrication

- Instrument Supports & Spray Nozzles

- FERC-Required Troughs and Shrouds

No matter the environment or engineering challenge, we deliver solutions that align with your project goals—on time, on spec, and ready for installation.

Need custom cryogenic supports or want to discuss your next LNG project?

Talk to an engineer today or Request a Quote

We’ll help you get the right solution—no delays, no surprises.

PT&P REF. ORIGINAL POST 05072013

-