Blog

High Temperature Pre-Insulated Pipe Supports with Slide Plates for an Ethylene Production Plant in Texas

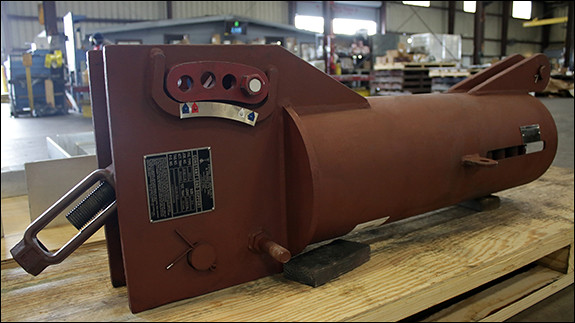

| Type: | High Temperature Pre-Insulated Pipe Supports with Slide Plates |

| Size: | 15″ Long | 23″ Wide | 4.5″ Insulation |

| Material: | Calcium Silicate, Firetemp®, Carbon Steel with HDG, UHMW Polyethylene |

| Design: | 750°F, 1,325 lb Operating Load, & 12″ Pipe Size |

| Testing: | Standard Quality Control |

PT&P custom designed these pre-insulated pipe supports for high temperatures at an ethylene production facility in Texas. The hot shoes are 15″ long and 23″ wide with 4.5″ thick insulation. The insulation is comprised of calcium silicate and Firetemp®. The hot shoes were fabricated from carbon steel with a hot-dipped galvanized finish and the slide plates from UHMW Polyethylene. They are designed as a 2-way guide than can support loads in two directions. They are designed for a pipe size of 12″ in diameter with an operating temperature above 750°F and on operating load of 1,325 lb. Standard quality control tests were performed with a 4-week turn-around time.

Read MoreField Service Inspection on Constant Spring Supports after 30 Years of Service on an Offshore Platform

|

|

The use of zinc and galvanizing has a long history. The early patents for hot-dip galvanizing were issued in France and England in 1836 and 1837. This technology was quickly adopted and was widely used in the late-1800s.

In the United States, we have bridges more than 100 years old which have galvanized structures. In addition, we have transmission towers and substation structures that are over 70 years old. A pipe rack at a petrochemical plant near Houston was studied after 28 years of service. Measurements of the zinc thickness remaining provided a forecast of another 60 years of service.

Any coating which provides a barrier to the moisture and oxygen in the air will help protect carbon steel from corrosion. A properly painted surface will provide a barrier, but it is subject to scratching from contact with hard objects.

Constant Spring Support Inspection:

Visually inspect each Constant hanger:

Search for signs of visual cracks, fractures, and corrosion of the spring casing and the following:

(1) beam attachment

(2) pin

(3) constant hanger attachment

(4) pipe clamp attachment

(5) weldless eye nut

(6) threaded rod

(9) spring coil

(10) Check if travel stops are removed

Check (7) turnbuckle (if present), locknuts (8) and other threaded items to ensure they are secured and fastened

Compare the position of the (10) coil with the hot/cold load indicator and operating range of the spring

Check the mobility of the (11) load column

Replacement Criteria:

– Signs of excessive corrosion or fatigue

– Rust damage of entire unit

– Modifications to operating conditions

– Consider condition of components (cam mechanisms, bearings, etc.)

Our field service team is available 24×7 for your quick-turn, emergency needs.

Call Field Service: +1-713-992-7048

Read MoreHydraulic Snubbers Designed for a Steam Generator in Mexico

| Type: | Hydraulic Snubbers |

| Size: | 24″ up to 30″ Pin-To-Pin | Cylinder Dia. 1.5″ to 3.25″ |

| Material: | Carbon Steel |

| Design: | 3,000 lb. to 20,000 lb., with a 6″ Stroke |

| Testing: | Standard Quality Control |

PT&P designed Fig. 510 AD short strut hydraulic snubbers for a steam generator at a facility in Mexico. The snubbers ranged in length from 24″ up to 30″ pin-to-pin with cylinder diameters of 1.5″ to 3.25″. A total of 48 snubbers were fabricated from carbon steel and designed for an operating load ranging from 3,000 lb. to 20,000 lb., with a 6″ stroke. Snubbers are used for systems where unrestrained thermal movement must be allowed except during cyclic disturbance. Hydraulic snubbers are designed to protect the piping system when a sudden, heavy load is applied (such as an earthquake of high intensity), which can cause serious vibrations leading to damage and possible failure of the piping system.

Read MorePre-Insulated Cryogenic Supports for Propylene Dehydrogenation

| Type: | Pre-Insulated Cryogenic Supports |

| Size: | 12” Long Base | 32” Wide Base | 62″ Overall Height | 18” Long Insulation |

| Material: | Polyurethane | Carbon Steel w/ HDG Finish |

| Design: | Operating Temperature -360°F & 42″ NPS |

| Testing: | Standard Quality Control |

Piping Technology and Products, Inc. and custom designed two pre-insulated cryogenic supports for a propylene dehydrogenation application at a petrochemical plant in Texas. The insulation is made from a high density polyurethane insulation, with the bearing plates and side bumpers fabricated from carbon steel with an HDG finish. The shoes are capable of insulating and supporting at temperatures as low as -360°F. These were designed to support pipeline diameter of 42” with overall height of 62” diameter. Regular quality control tests were performed with a standard turn-around time.

Read MoreC-Type Constant Springs Designed for a Chemical Plant in Italy

| Type: | Constant Spring Supports |

| Size: | 14″ x 19″ x 64″ |

| Material: | A36 Carbon Steel |

| Design: | 2 1/2” to 5” Total Travel and 7,681 lb. Load |

| Testing: | Standard Load and Travel Tests |

PT&P custom designed and manufactured C-Type constant spring supports for a chemical plant in Italy. The constants were designed for travel from 2 1/2” to 5” and are specified to carry a load of 7,681 lb. They are fabricated from A36 carbon steel and have a physical size of 14″ x 19″ x 64″. The supports were designed for max deviation of 6%. The standard load adjustment is 10%. However, this unit was designed with capability of up to 20%, while the standard load deviation is 4%. This constant was custom designed to allow for single pin connection with negligible constant frame at the pin connection. A multi-position locking device was installed, and standard load and travel tests were performed to ensure quality and precise performance.

Read MoreHappy Holidays From Piping Technology & Products!

Santa counts on us for quality products and so can you!

Please enjoy our annual Holiday video. Happy Holidays from all of us at Piping Technology & Products!

Custom Designed Big Ton Spring Supports for a Propane Dehydrogenation Application in Texas

| Type: | Big Ton Spring Supports |

| Size: | 42″ x 24″ x 26 1/2″ |

| Material: | Carbon Steel |

| Design: | 94,261 lb. Load & 0.085” Movement |

| Testing: | Standard Load Tests |

PT&P custom designed big ton spring supports for a propane dehydrogenation application at a chemical plant in Texas. The components within this assembly include the spring housing, coils, name plates, pressure plate, and load indicator. While both assemblies measure 42” L x 24” W x 26-1/2” H, it was modified based on independent specifications for operating loads and movement to accommodate a load of 94,261 lb. and 0.085” of movement. This type of support is ideal for applications, such as supporting pressure vessels that combine very heavy loads with thermal expansion because of the stability they provide. The big ton was tested in the load cell to insure proper operation throughout the entire working range of the coils.

Read More