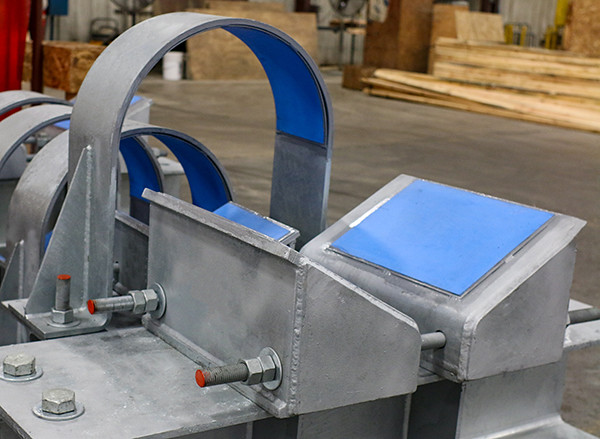

These hold-down pipe clamp assemblies are specially fabricated and include wedges with 25% glass-filled PTFE to absorb vibration and also serve as a buffer between the steel pipe and pipe support. Vibration can occur in Power, Solar, Biofuels, and Chemical plants because of flow-induced and/or acoustic-induced vibration due to the flow of fluids or gas/steam through the piping system. Similarly, vibration can occur in pipelines near rotating equipment such as reciprocating pumps and compressors resulting in pulsations or mechanical forces that can occur in both onshore or offshore production facilities. Vibration can be strong enough to cause premature failure or cracks resulting in unplanned shutdowns. These units shown in the photograph are custom-designed for pipe sizes up to 20″ in diameter and temperatures up to 200°F and can be adjusted to accommodate a range of heights for the T.O.S to the B.O.P. They are 21″ wide x 26″ long x 23″ high and are proven to greatly reduce vibration to acceptable levels. These hold-down pipe clamps are fabricated utilizing A 36 carbon steel plate and A 307 Gr. All-threaded rods. All components were hot-dipped galvanized and a quality control inspection was performed before shipment.

Read MoreBlog

Cable Tray Support Rack Fabricated for a Groundwater Remediation

PT&P provided a cable tray support rack to a groundwater treatment facility in California. Groundwater remediation is a process whereby groundwater is purified by removing pollutants and containments rendering the water useful for crop irrigation and industrial processes. Groundwater remediation techniques can include but are not limited to, oxygen gas injection, dual-phase extraction, membrane separation, carbon absorption, and chemical oxidation. Cable trays, used in this facility, were designed to suspend electrical cables, wiring, and small-bore piping throughout the facility. Cable trays are also used in biochemical plants, solar power plants, sports stadiums, green energy plants, as well as, traditional plants such as petroleum refineries, chemical and coal-fired power plants. As a general rule, cable trays protect and carry cable and wiring from point “A” to “B” inside the facility.

This section of cable tray in the photograph (blue in color) is 25’ long, 7’ wide, and 11’ tall completely assembled. It is fabricated from carbon steel and painted with a highly chemically resistant epoxy mastic designed for immersion conditions to protect against corrosion in marine or industrial conditions. PT&P can fabricate any combination of instrument stands and structural supports from floor mounts, wall mounts to secondary supports, and more. In addition, we have the capabilities to do what few other structural fabricators can do including:

– Complete Engineering designs including FEA (Ansys) and Structural Engineering (STAAD)

– Load Testing

– Incorporation of Contact Corrosion Solutions including TPI (half-round thermoplastic) and FRP

– Incorporation of Vibration Control Solutions

– Ability to fabricate with a wide variety of metals including all grades of Stainless and Nickel Super Alloys

PT&P has worked on and is working on some of the largest water remediation projects in the US where we have supplied expansion joints, variables, fire protection insulated supports, and structural pipe supports. Our ASME shop is large, local to the United States, and includes heavy-duty equipment and specially trained personnel with over 45 years of experience making this division of PT&P ideal for large-scale projects such as this structural support as we can leverage our massive manufacturing scale and expertise.

Read MoreCustom-Designed Bird Screens for LNG Service Provide a Humane Deterrent

PT&P custom-designed bird screens for a 3″ diameter pipeline at an LNG facility. Bird screens (or insect screens) are used on an open-ended pipe (i.e. exhaust) where birds or insects can be trapped inside the pipe creating a blockage. Birds such as pigeons and other roosting birds often build nests inside exposed piping and their droppings can carry diseases and even pose potential contamination and health hazards. Bird droppings have even been known to cause damage to sensitive equipment such as valves and gauges not to mention creating safety hazards on ladders, steps, and catwalks. It’s best to incorporate bird screens during the design of the refinery, chemical, power, LNG, or green energy plant and install them during construction. Our bird screens are fabricated from corrosion-resistant 304 stainless steel and can withstand temperatures up to 800 degrees Fahrenheit. They are designed to be easily assembled in the field without requiring a skilled welder or special equipment. PT&P can provide bird screens for any size piping or configuration.

Read More

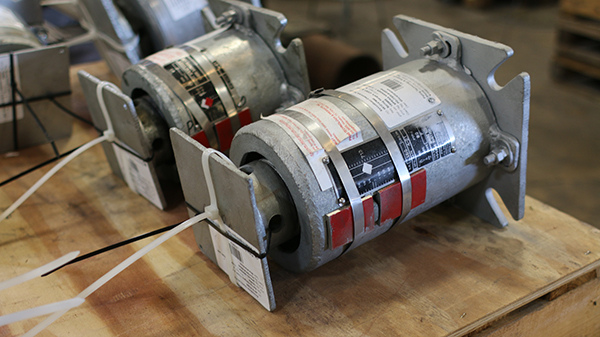

Pipe Rollers for an Environmental Remediation Project

These pipe rollers were designed for pipelines in an environmental remediation project. These rollers can also be used in conjunction with piping on bridges, landfill gas equipment, including oil-water & moisture separators, SVE systems, candlestick flares, blower packages, drainage systems, and many other infrastructure projects. The rollers are fabricated from cast iron, with a carbon steel frame, rods, and nuts. The units are designed for 14″, 18″, and 24″ pipe sizes and 5,000 to 7,200 lb. operating load. The rollers are designed to include 1-1/2″ thick insulation, and the size is selected to include the pipe covering saddle for the insulation. Standard quality control tests were performed prior to shipment. Roller hangers are used for the suspension of pipe from a single rod where axial movement may occur because of expansion or contraction.

Read MoreVariable Spring Hangers Designed for a Biofuels Plant

PT&P designed and fabricated B-Type variable spring support assemblies for a biofuels plant. The variables will support pipelines that are involved in the process of converting feedstock into low-carbon synthetic crude oil. Primary biofuels are bioethanol and biodiesel. PT&P specializes in manufacturing pipe supports for high temperatures (above 750°F) applications. These variable springs will support loads up to 953 lb., insulated piping up to 1625°F, and with 1.5” upwards movement. A custom-designed 4-bolt riser clamp fabricated from A36 carbon steel for a 3” diameter pipe was also supplied for this order and used at another location in the plant. The rest of the variable spring assemblies utilized custom-designed 2-bolt pipe clamps manufactured from A240 316L stainless steel plate with A 193 GR. B8M CL.1 bolting for high temperatures. Since these variable springs were located outside the firebox and not exposed to high temperatures, they were fabricated from A36 carbon steel and hot-dipped galvanized for corrosion protection. Load and travel tests, along with Q.C. inspections were performed before shipment.

Load and travel tests, along with Q.C. inspections were performed before shipment. Biofuels are expected to double their market share by 2027. Biofuels are a subset of the new emerging demand and regulatory shift to renewables being seen in the energy sector. In addition to biofuels, other renewables include energy from solar, wind, hydroelectric, ocean, geothermal, and hydrogen sources. There has been a change in strategy for many refineries accelerated by the downturn due to COVID, to convert traditional fossil fuel refineries to renewables. With expertise and over 45 years of experience, PT&P is well-positioned to serve its customers and emerging players in the renewable energy sector. Piping Technology & Product’s specialty is the design and fabrication of products like furnace springs, constants, customized clamps, and hardware in supporting high-temperature headers and radiant coils within fired heaters.

Read MoreHigh-Temperature Supports Designed for a Petrochemical Plant

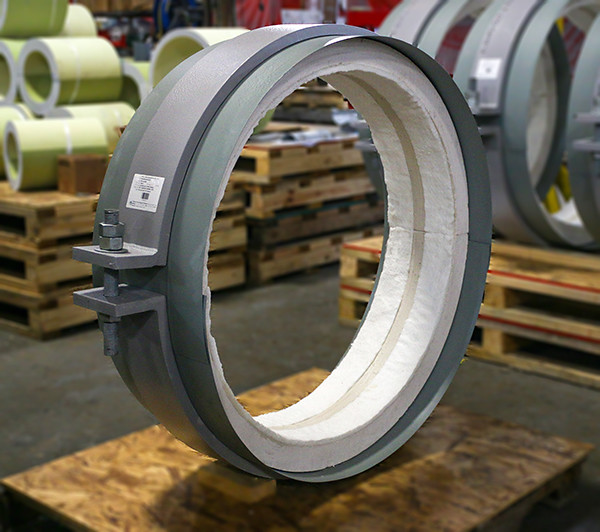

Pipe Shields, Inc., a division of PT&P designed pre-insulated pipe supports for a high-temperature pipeline at a petrochemical plant overseas. This style of insulated support is designed to be compact, easy to install and eliminate the need for field welding. The insulation is 5-1/2″ thick utilizing 18 lb. and 28 lb. pcf high-density calcium silicate. The “hot shoes” are fabricated from carbon steel and hot-dipped galvanized for corrosion protection. They are rated for temperatures from +40°F to +1800°F. Q.C. inspections and dimensional tests were performed before an expedited shipment.

Such insulated supports are used for chilled water, hot water, and steam line applications in industries ranging from pharmaceutical, semiconductor, paper mills, chemical plants, data centers, biofuels, and food processing to name a few. Piping Technology and Products, through its subsidiary, industry leader, and pioneer, Pipe Shields, has supplied to all these markets in the USA and internationally for over 45 years. Most recently, we made a large investment to automate manufacturing in our Houston plant to increase throughput and yield to support our customers’ needs for just-in-time deliveries reducing cash requirements on projects.

View Pipe Shields’ Model D3100 – Insulated 2-Bolt Hanger

Read MoreVariable Supports Fabricated in 48 hours for an Emergency Plant Shutdown

PT&P received a rush order this past week for variable spring supports at 4:41 pm, quite late into the workday; however, this is business as usual, our manufacturing facility in Houston, TX operates 24/7 to support our customers.

In this case, the customer facility, an olefins plant was incurring a significant loss and needed to replace the springs to resume operations as quickly as possible. The seven (7) variable springs were designed, fabricated, and shipped within 2 days. The F-type variable spring support is designed to support piping from below, directly from the foundation, concrete column, or supporting structural pipe rack steel. Adjustment is made by inserting a bar into holes in the load column and turning the load column as a jackscrew. The base plate is bolted to the case and has four holes for fastening.

As global leaders in variable spring manufacturing, we used our adaptive manufacturing processes in which the PT&P pre-fabricated component parts that make up these variables are easily assembled when orders are placed. These variables were fabricated from carbon steel and hot-dipped galvanized for corrosion protection. They are designed to support loads ranging from 713 lb. to 1668 lb. and movements of 0.148” to 0.133”. Load and travel tests, along with Q.C. inspections were performed before shipment. Variable springs are used in mills, refineries, chemical, plastics, polymer, solar, power, biochar, renewables, carbon black, LNG boilers, food, packaging, and wastewater treatment plants to support piping as it goes through its’ range of movement.

ASME Defines Inspection Criteria for High Energy Piping

B31.1 Operations and Maintenance

According to ASME B31.1 Chapter VII Par. 140 a program shall be established for the assessment and documentation of the condition of all CPS (Covered Piping Systems) in power plants.

CPS Systems are defined in Chapter 1 Par 100.2, as systems on which condition assessments are to be conducted. This includes the following systems as a minimum.

NPS 4 and larger main steam, hot reheat steam, cold reheat steam, and boiler feedwater piping.

NPS 4 and larger systems that operate above 750°E (400°C or above 1,025 psi (7,100 kPa)

Other systems may be included as CPS by an Operating Company, based on their judgment. Appendix V of the code is titled ‘Recommended Practice for Operation, Maintenance, and Modification of Power Piping Systems’. This addendum is non-mandatory; however many Power Industry operating companies’ insurance carriers are now invoking Appendix V with increasing frequency, and this is affecting the conditions of their agreements with the operating companies.

Piping Technology and Products Inc. (PT&P) has for some time been performing surveys and assessments in accordance with part H of Par. 140, which requires hot and cold walk-down readings and assessment of pipe supports, operated within the creep regime of the pipe. These assessments are helpful in identifying, sagging lines, deformation of supports, and damage caused by upset conditions, and/or incidents, attributable to operational malfunctions, dynamic/thermal or hydraulic events.

PT&P has been performing this service for many power generation companies. Preparation of documentation, retrieval, and compilation of files for a CPS assessment, has just been completed for a major U.S power generation company. Ten large power plants were involved, and the original predominantly high-energy pipe support drawings, all engineered and designed by PT&P, were retrieved from PT&P archives dating back ten years.

We will be happy to answer any of your technical questions about our survey capabilities, as well as any other engineering or field services that your organization may need.

If you need assistance, we are available 24×7 for emergencies or reach our field service team directly.

Read More

High-Temperature Pre-Insulated Pipe Supports Designed for 42″ Dia. Pipelines

Pre-Insulated pipe supports were designed for high-temperature service at an oil refinery for a client that specializes in the engineering and design of fired heaters, furnaces, pre-heaters, and heat recovery systems. These high-temperature pipe supports were fabricated from carbon steel and designed for pipe sizes ranging in 36” – 42” diameter and are not only used for new construction but also upgrades and revamps. The “hot shoes” were designed with the addition of “Spring Washers” (not shown here) to maintain consistent clamping force when the pipe expands and contracts. The insulation is 3″ thick and comprised of High-density Calcium Silicate (asbestos-free) structural inserts treated with water repellant. Standard quality tests were performed before shipment. Our hot shoes are used extensively in Refineries, Styrene Plants, Hydrogen Plants, LNG Facilities, Semiconductor Fabrication Facilities, and General Building Construction.

Read MoreConstant Spring Supports for a Leading Energy Transportation and Midstream Service Provider

PT&P custom-designed constant spring support assemblies for an energy facility in Canada. These 100–E Type (layout B) constants were supplied with an extended hanger rod and fabricated from A36 carbon steel with 5160 alloy steel coil springs. They are designed for an operating load from 2,370 lb. to 9,240 lb., and movements from 1-1/2” to 8-1/4”. The dimensions are 12” W x12” L x 30” H and 14” W x 19” L x 53” H. Load and travel tests along with a quality control inspection were conducted prior to shipment.

Read More