Blog

Adjustable Pipe Stands Designed for a Crude Oil Terminal in Texas

| Type: | Adjustable Pipe Stands / Saddles |

| Design: | 3″ to 25″ Dia. | +/-2″ Adjustment |

| Material: | Carbon Steel with a HDG Finish |

| Function: | Allow adjustment after expansion and contraction |

Piping Technology & Products, Inc. designed and fabricated fifty-seven adjustable pipe stands for a Crude Oil Terminal in Texas. All the supports are fabricated from carbon steel with a hot-dipped galvanized finish. They are designed for 3″ to 25″ diameter pipelines with +/- 2″ of adjustment. Each base plate has been pre-drilled to accept anchor bolts provided at the site. The function of the pipe stand is to allow for adjustment of the support after expansion or contraction of the pipeline.

Read MoreHeavy Duty Pipe Saddles Designed for an Ethane Cracker

| Type: | Heavy Duty Pipe Saddles |

| Design: | 60″ Dia. | 23-5/8″ Length | 5-18″ from BOP |

| Material: | Carbon Steel with a HDG Finish |

| Testing: | Visual | Sample Pipe | Dimensional |

Piping Technology & Products, Inc. designed and manufactured these heavy duty pipe saddles for the Ethylene Plant Project in Texas. The saddles are fabricated from A36 carbon steel with a hot-dipped galvanized finish and designed to support pipes up to 60″ in diameter. They measure 23-5/8″ in length and 5-1/8″ from BOP. Standard Q.C., visual inspection with a sample pipe and dimensional tests were performed prior to shipment.

Read MoreVariable Spring Supports Designed for a Furnace Application in Oklahoma

| Type: | Variable Spring Supports |

| Design: | 1,765 lb. Load | +/- 5% Spring Rate |

| Material: | Carbon Steel with Red Oxide Primer |

| Testing: | Standard Spring Rate & Calibration Tests |

PT&P custom designed variable spring supports for a furnace application at a Nitrogen Facility in Oklahoma. The furnace springs are fabricated from carbon steel and painted with a red-oxide primer to help prevent corrosion. The spring supports are designed to support loads up to 1,765 lb. With a spring rate calibrated to be within +/- 5% of the theoretical value.

Read MoreSingle Expansion Joints Product Video

Big Ton Spring Supports Custom Designed for an LNG Facility

|

PT&P custom designed big ton spring supports with PTFE slide plates for an LNG facility in Australia. The components within the spring housing include load columns, travel stops, spring coils and lifting lugs. Each assembly is designed for an operating load ranging from 16,276 lb. to 34,479 lb. and will allow for movement between 0.16″ and 0.24″. They are fabricated from hot-dipped galvanized carbon steel and measure 29-7/8″ x 29-7/8″ x 16-1/2″. The big ton spring support is ideal for applications that have very heavy loads with thermal expansion because of the stability they provide throughout the range of travel. These supports were tested in the press connected to a load cell to insure proper operation throughout the entire working range of the coils.

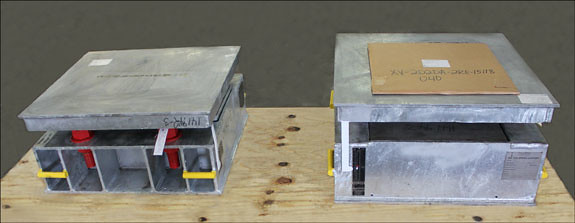

Read MoreCold Insulated Pipe Saddles with Slide Plates Designed for an Ethane Cracker at a Plant in Texas

PT&P designed cold insulated pipe saddles with PTFE slide plates to provide sliding and guiding support for horizontal piping leading to an ethane cracker at a plant in Texas. The project fulfilled an emergency request when the client realized the product was missing at time of installation. The pipe saddles are fabricated from carbon steel with a hot-dipped galvanized finish for pipe sizes ranging from 3″ to 56″. They have a diameter of 40″, height of 23-5/8″, width of 42-1/2″ and 11-7/8″ BOP. Visual inspection and dimensional checks using a section of pipe were completed prior to shipment.

Read MoreConstant Spring Supports Design and Application Webinar

This webinar is over, view the recording in the webinar archives

This Webinar will focus on the different types of constant spring supports. Learn about the special features available, in addition to the design of a constant support. View how the different cam/coil configurations produce a unique response to an applied load. Discover the step by step process used to size a spring for your application. Learn about the different attachments, testing, and installation and maintenance procedures. View examples of failed supports provided by our Field Service Division and learn why they failed and how to prevent it. Gain knowledge of the valuable tips used when deciding to adjust or replace a constant spring support, as well as shutdown and isolation procedures.

The featured presenter, Jerry Godina has over 15 years experience as a pipe support designer and manages PT&P’s engineer training development program. He also inspects existing supports, consults on site remediation projects and oversees installation on a regular basis.

Read MoreVariable Spring Supports Product Video

127 Cryogenic Insulated Pipe Supports Designed for a Chemical Plant

PT&P custom designed 127 cryogenic insulated pipe supports for a chemical plant in Texas. They are designed for pipe sizes ranging from 1″ – 24″ diameter and operating loads up to 120,517 lb. The insulation is high density polyurethane foam (PUF) ranging from 1″ to 7″ in thickness. The shoe and bearing plates were fabricated from carbon steel with a hot-dipped galvanized finish. The jacket was fabricated from aluminized steel and includes a vapor barrier. Standard Q.C. and dimensional tests were performed prior to shipment.

Read More