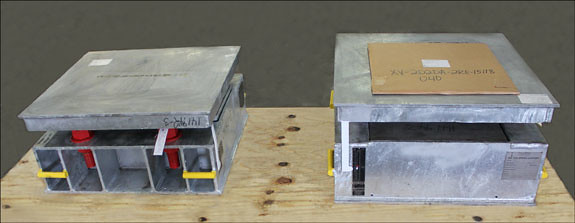

PT&P custom designed big ton spring supports for a propane dehydrogenation facility in Texas. The components within these assemblies include the spring housing, load columns, travel stops, spring coils and lifting lugs. While both assemblies measure 42” x 24” x 26-1/2”, they were each modified based on independent specifications for operating loads and movement. The first will accommodate a load of 94,261 lb. and 0.085” of movement, while the second will accommodate a load of 102,219 lb. with 0.08” of movement.

This type of support is ideal for applications, such as pressure vessels, that combine very heavy loads with thermal expansion because of the stability they provide. The big tons were tested in the load cell to insure proper operation throughout the entire working range of the coils.

Read More

This webinar will give you an introduction to Pipe Shields, Inc. and its unique line of pre-insulated pipe supports, slides, guides and anchors that it developed and patented over it’s 40 year history. It will cover various designs, commercial applications (chilled and heated water lines, HVAC systems and low pressure steam lines), installation and maintenance procedures and the benefits of using pre-insulated pipe supports (vs. doing insulation in the field). This webinar will be delivered by Albert Dizon, General Manager of Pipe Shields, who has been working with pre-insulated pipe supports for 30+ years. Join us and receive some of his experience and wisdom!

This webinar will give you an introduction to Pipe Shields, Inc. and its unique line of pre-insulated pipe supports, slides, guides and anchors that it developed and patented over it’s 40 year history. It will cover various designs, commercial applications (chilled and heated water lines, HVAC systems and low pressure steam lines), installation and maintenance procedures and the benefits of using pre-insulated pipe supports (vs. doing insulation in the field). This webinar will be delivered by Albert Dizon, General Manager of Pipe Shields, who has been working with pre-insulated pipe supports for 30+ years. Join us and receive some of his experience and wisdom!

This presentation will cover Pipe Clamps, including Hold-Down Clamps, Riser Clamps, Clevis Hangers, Yoke U-Bolt Clamps and Structural Supports. Learn how the appropriate type of pipe support is chosen based on the different design conditions. Find out how Finite Element Analysis is used in the design process and view the custom pipe supports designed for extreme applications.

This presentation will cover Pipe Clamps, including Hold-Down Clamps, Riser Clamps, Clevis Hangers, Yoke U-Bolt Clamps and Structural Supports. Learn how the appropriate type of pipe support is chosen based on the different design conditions. Find out how Finite Element Analysis is used in the design process and view the custom pipe supports designed for extreme applications.