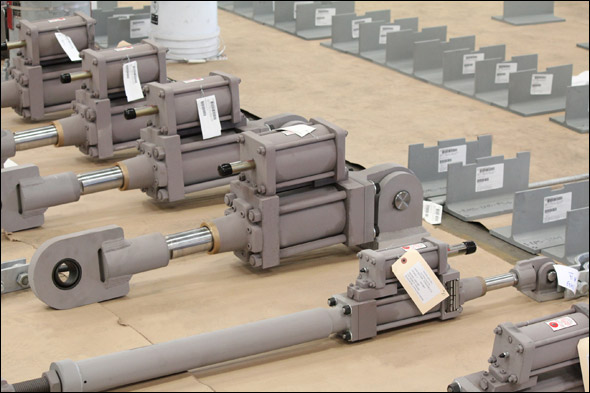

Fronek Anchor/Darling Enterprises, a division of PT&P designed and fabricated hydraulic snubbers for a geothermal facility in California. The Fig. 510 AD snubbers ranged in size from 34-3/4″ to 37-5/8″ piston-to-piston and were designed for a 50,000 lb. maximum load, 5″ cylinder size and a 6″ stroke. The Fig. 511 AD snubbers ranged in size from 56-15/16″ to 59-5/16″ P-P and were designed for a 20,000 lb. maximum load, 2-1/2″ cylinder size and a 6″ stroke. Hydraulic snubbers are designed to protect the piping system when a sudden, heavy load is applied (such as an earthquake of high intensity), which can cause serious vibrations leading to complete destruction. A custom three-bolt pipe clamp fabricated from carbon steel was designed to fit in a limited space. A cycle test throughout the full stroke from zero to fully extended was performed prior to shipment.

Read MoreBlog

7 Ways to Extend the Lifespan of a Hydraulic Snubber

Follow these 7 steps below to maintain and extend the life span of your hydraulic snubber.

1. Observe the fluid level to make sure there is sufficient fluid for the snubber to operate

2. Check for leaks – If the fluid level is decreasing, determine the cause and effect remedial action.

3. Check the condition of the load pins and spherical ball bushings. Apply a high pressure grease for long-term benefits.

4. Check the condition of the exposed portion of the piston rod. Check for scoring, paint or other physical damage.

5. Check the condition of the piston rod wiper. Verify that it’s in position and working effectively.

6. Check for evidence of abuse like welding arc strikes, bent or dented parts, scratched paint, etc.

7. Finally, check the overall physical appearance. This encompasses all of the above.

Read More

Variable Springs with Guided Load Columns and PTFE Lined Pipe Saddles

These F-type variable spring supports are fabricated from carbon steel with a hot dipped galvanized finish and designed with guided load columns to provide stability for minimum lateral movement. The fig. 46 pipe saddles are also fabricated from carbon steel with a HDG finish and lined with PTFE, 25% glass filled material. The pipe saddles are designed for 8″ to 36″ diameter pipe sizes, and the entire assembly is 50″ in height. These variable-saddle support assemblies are capable of supporting up to 22,300 lb. and 1″ vertical movements. We performed standard spring loading tests and a Q.C. inspection prior to shipping to an offshore oil and gas platform near Malaysia.

Read MoreMaintaining your PTFE Slide Plates

Slide plates are easy to maintain if you follow these certain steps when inspecting them. Visit our visual media section to learn what four steps to take for Slide Plate Inspection and Maintenance.

Our field service manager, David Baker, will show you what to look for when inspecting your PTFE slide plates. If you have any questions, feel free to call David Baker at 713-992-7048 or email us at info@pipingtech.com.

Read MoreCustom High Temperature Pipe Supports for a Granular Activated Carbon Manufacturing Plant

These high temperature pipe supports have a 25″ outside diameter, and were custom designed for a granular activated carbon manufacturing plant in Hawaii. They are fabricated from A-36 carbon steel with 10″ thick high density calcium silicate insulation. The hot shoes were designed for a 4″ diameter pipe-line, temperatures up to 1,800°F and an operating load of 1,000 lb. Standard Q.C. and dimensional tests were performed prior to an expedited shipment.

Do you require hot shoes on an upcoming project? Get pricing today!

Four Steps to Inspecting Your Hydraulic Snubber

Do you have a hydraulic snubber would you like inspect, but don’t know where to begin? Visit our visual media section and learn How To Inspect a Hydraulic Snubber.

This video will go over the four main steps when inspecting a hydraulic snubber. If you have any questions, feel free to call us at 713-731-0030 or email us at info@pipingtech.com.

Read MoreStock Upthrust Constants Modified with an Auxillary Platform

These 200 U-Type constant spring supports were modified to increase their installed height by adding a secondary plate and angles, which will be welded to the structural beam. The constants range in size from 25″ to 27″ in height, 52″ to 67″ in length, and 25″ in width. Their load capacities range from 10,300 lb. to 13,000 lb. with vertical movement ranging from 3″ to 4-1/2″. All constants were fabricated from A-36 carbon steel, and went through standard load and travel testing per MSS Standards prior to shipment.

Do you have a similar application that requires upthrust constants? Get pricing today!

Happy New Years from the PT&P Team

PTP-1 F-Type Variable Spring Assemblies

These PTP-1 F-Type variable spring assemblies fabricated from A-36 carbon steel, were custom designed to accommodate a height of 11-11/16″ while keeping the same spring rate. The F-Type variable is used to support the pipe from below and are typically mounted to concrete pads via anchor bolts or welded to structural steel. The variables are designed for loads up to 6,500 lb. and a total upward travel of 5/16″.

Want to learn more about variable springs? Check out a recording of a past live webinar.

48" Diameter Stainless Steel Glycol Makeup Tank Fabricated By Our Sweco Fab Division.

This Glycol Makeup Tank is fabricated entirely from ASTM A240-304 stainless steel and is rated for 0 psig at 150°F. The tank has a 1,000 gallon capacity and measures 48″ I.D. x 10′-8″ seam-to-seam. The stand pictured behind is also fabricated from stainless steel and measures 11′ high. The customer ordered six additional units and all the Makeup Tanks underwent leak testing prior to shipment.

Do you require a tank or vessel for an upcoming project? Let us price it for you today!