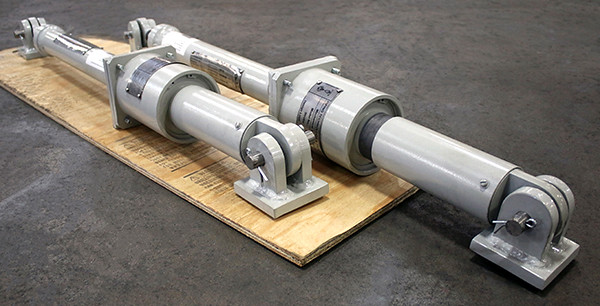

| Type: | Heavy-Duty Pipe Saddles |

| Size: | Up to 48” Diameter |

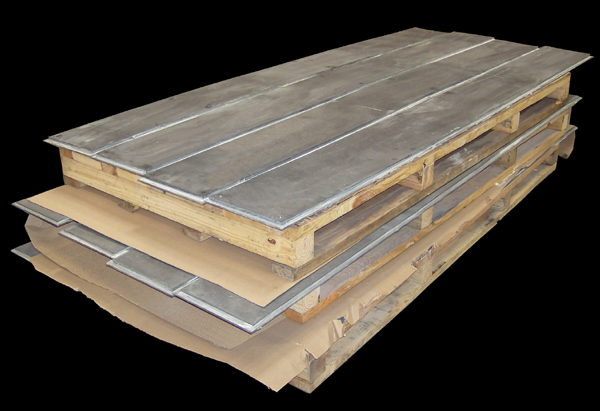

| Material: | A36 Carbon Steel |

| Testing: | Q.C. Visual Inspection | Pipe Dimensional Tests |

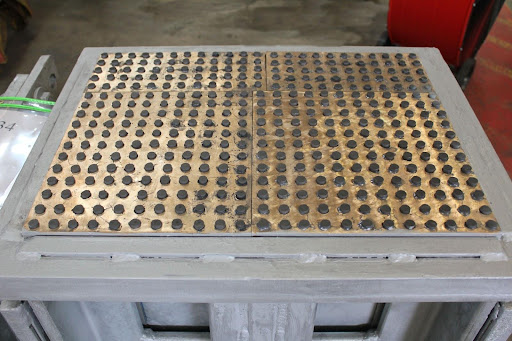

This week’s featured product, Piping Technology & Products, Inc. custom-designed heavy-duty pipe saddles for an LNG facility in Louisiana. The pipe saddles are part of a large liquefaction project and range in size. The largest pipe saddle will support a 48” diameter pipeline. They are fabricated utilizing A516 Gr70N low-temperature carbon steel base plates, and web plates. Standard Q.C., visual inspection with pipe dimensional tests were performed prior to shipment. A pipe saddle is a structure consisting of a saddle and integral base used to support the pipe by transmitting the load or forces to the adjacent structure. Since we are a custom fabrication shop, we specialize in the design and manufacture of pipe shoes and saddles to accommodate sloping lines, pipe elbows, hot and cold temperature lines, as well as storage tanks and pressure vessels. In addition to pipe saddles, we have also supplied a wide variety of pipe supports to LNG projects, as well as, Floating Rings. Below is just a brief list of supports supplied to LNG projects from our product portfolio:

Pipe Hanger Hardware

Cryogenic Insulated Shoes-G10 as well as PUF

Our products have gone into all key components of LNG facilities ranging from the liquefaction plant, the flare lines, loading lines, the terminals, and storage tank facilities.

PT&P REF. ORIGINAL POST 01082020

Read More