| Type: | Compact Spring Supports (Disc Springs) |

| Material: | Carbon Steel | PTFE, 25% Glass-Filled |

| Design: | Movement: 1/32″ to 1/4″ | Load: 12,000 lb. |

| Testing: | Standard Spring Rate & Calibration Tests |

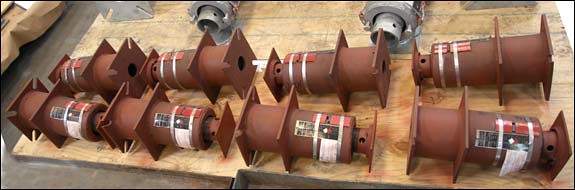

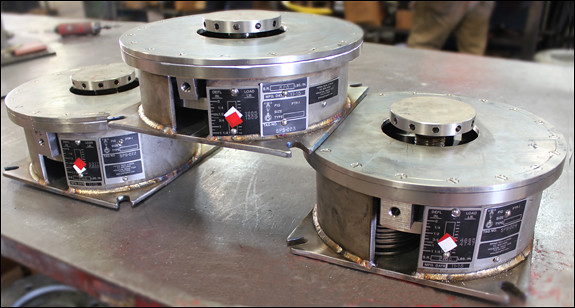

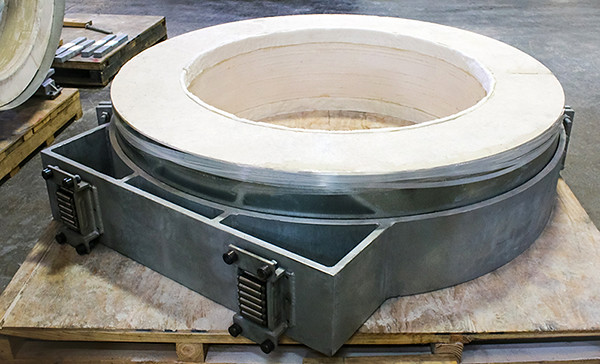

These compact spring supports were custom designed for an oil refinery expansion project. They will be installed underneath a heat exchanger supporting a load of up to 12,000 lb. The space available was limited to 3" for the installed height, and the movements ranged from 1/32" to 1/4". These units are the perfect solution for tight spaces where the distance between the supporting steel and the equipment/pipeline is extremely limited. These compact springs are fabricated from carbon steel and utilize engineered Belleville (disc spring) washers to achieve the desired spring rate. 25% glass-filled (PTFE) slide plates are bonded to the top of the load flange and provide a low coefficient of friction in order to adjust the spring’s height.

Here at Piping Technology and Products, we manufacture a wide range of variable spring supports along with constant spring supports. Our experience and know-how have helped to facilitate designs to incorporate site conditions where no conventional support is available.

PT&P REF. ORIGINAL POST 03092017

Read More