|

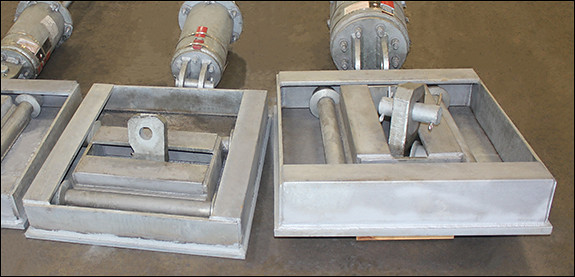

These 3-layer pre-insulated cryogenic pipe shoes were custom fabricated by Piping Technology& Products for a light hydrocarbon chemical plant in Texas. The insulation foam is made from polyurethane and the rest of the shoe components from carbon steel with HDG finish. The cold shoes are designed for 18″ pipe, the 3-layers of insulation total is 5.5″ thick, the clamps are 12″ wide, and cryogenic operating temperature. Standard quality control tests were performed prior to shipment.

Read More