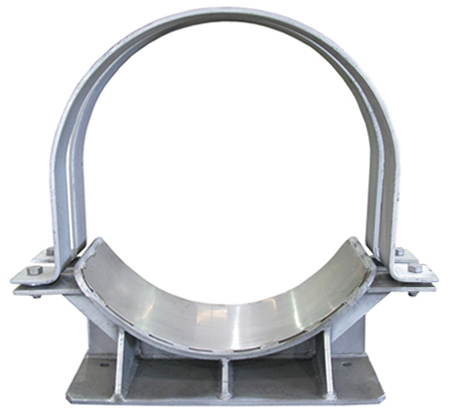

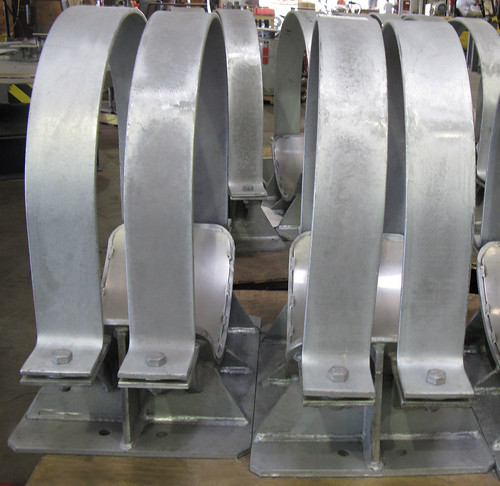

PT&P custom designed seventy-eight figure 2000 heavy duty pipe saddles for two 24″ insulated ductile iron pipelines. The two pipelines are routed beneath a 650′ bridge crossing over a river in upper New York State. The insulation is 3″ thick with high density polyethylene jacketing. Axial movements due to expansion can approach 3″. In order for the jacketing to avoid being damaged when displacements occur, the saddles have been lined with polished stainless steel.

Would you like to order similar pipe saddles for your current or future job? Get pricing!